UHP tire for improving wetland performance

A tire and performance technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems that safety and stability cannot be guaranteed, and cannot meet the needs of automobile use, so as to improve safety and stability , Improve water breaking ability, suitable size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

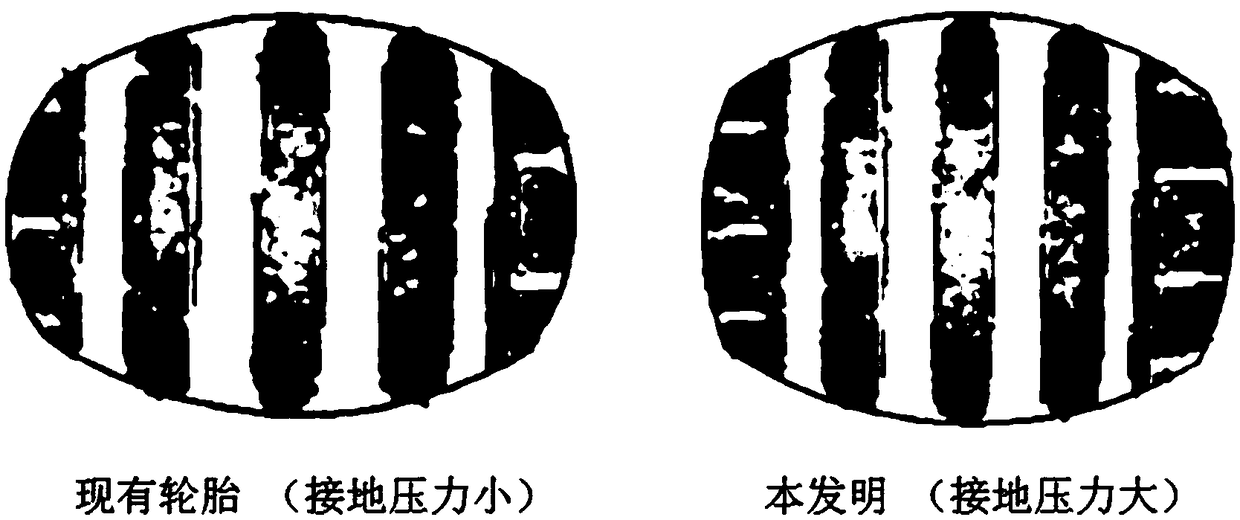

[0043] see figure 1 with figure 2 , a UHP tire for improving wet performance, comprising a tread with a crown arc with a total length of TDW, and the relationship between the total length of the crown arc TDW and the nominal section width SN of the tire is 0.80≤TDW / SN≤0.82, preferably The ratio of TDW / SN is 0.81; the tread of the tire is equally divided into two parts with a crown arc length of 0.5TDW by the equatorial plane CL of the tire, and the crown arc length of each part is half of the total length of the tire crown arc. And each part of the crown arc length of 0.5TDW includes three sections of contour curves successively connected from the equatorial plane CL to the tire shoulder, so that on the tire meridian section, the contour curve of the tread extends from the tire equatorial plane to the tire shoulder. The intersection point of the surface profile to the tread end of the shoulder is divided into a first profile curve with an arc length of TW1, a second profile ...

Embodiment 2

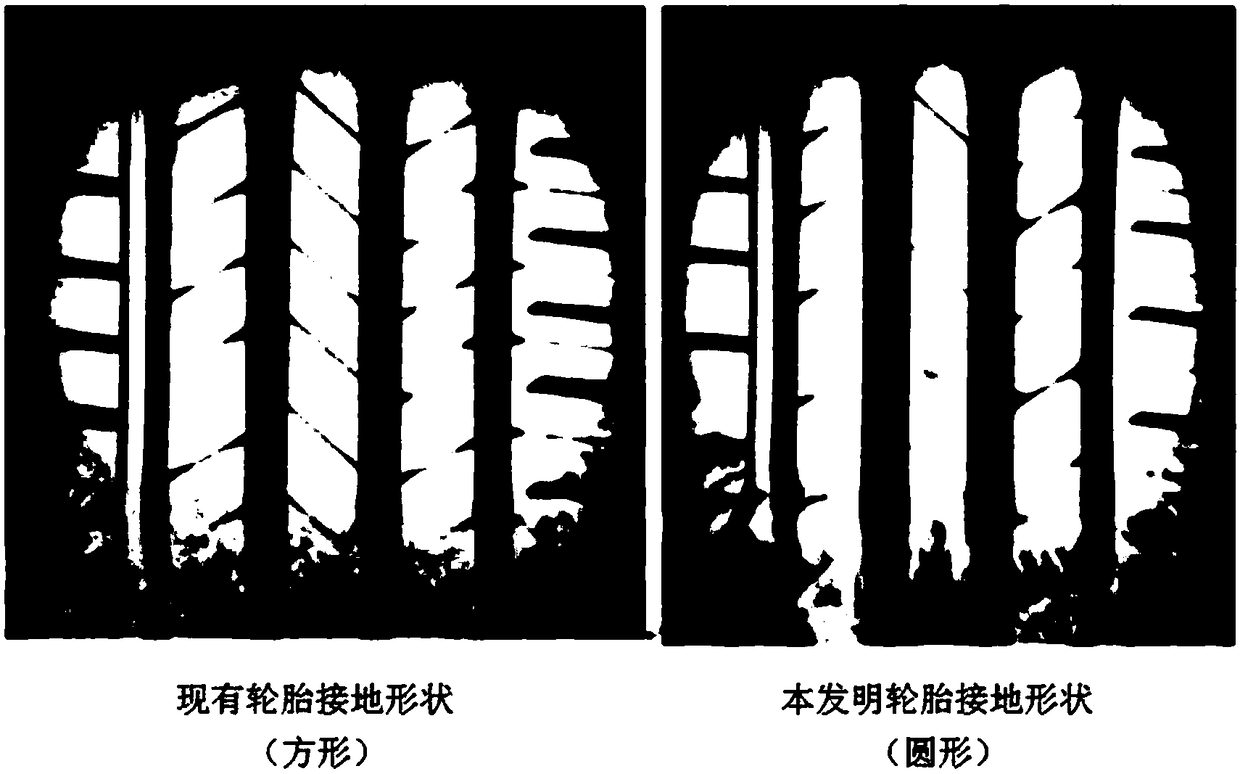

[0047] see Image 6 The tread of the tire is provided with longitudinal main grooves and a plurality of pattern blocks defined by adjacent longitudinal main grooves, and the longitudinal main grooves include first longitudinal main grooves 1, second longitudinal main grooves opened sequentially in the tire width direction The longitudinal main groove 2, the third longitudinal main groove 3 and the fourth longitudinal main groove 4; the width of the first longitudinal main groove 1 is a, the width of the second longitudinal main groove 2 is b, the width of the third longitudinal main groove 3 is The width is c, the width of the fourth longitudinal main groove 4 is d, there is a relationship of (a / TDW): (b / TDW): (c / TDW): (d / TDW) = 0.09: 0.17: 0.17: 0.13, The sea-to-land ratio of the tire is controlled at about 36.3%, thereby optimizing the total groove area and the total contact area of the tire; at the same time, (a / TDW): (b / TDW): (c / TDW): (d / TDW)=0.09:0.17:0.17:0.13, each ...

Embodiment 3

[0053] see Figure 6-8 , the pattern blocks include the outer pattern block 14, the first shoulder block 5 defined by the first longitudinal main groove 1 and the second longitudinal main groove 2, the second longitudinal main groove 2 and the third longitudinal main groove 3 defined The crown block 6, the second shoulder block 7 defined by the third longitudinal main groove 3 and the fourth longitudinal main groove 4, and the inner tread block 13, the inner tread block 13 is arranged on the fourth longitudinal main groove 4 away from One side of the second shoulder pattern block 7 and the outer pattern block 14 are arranged on the side of the first longitudinal main groove 1 away from the first shoulder pattern block 5, and the side of the inner pattern block 13 is provided when the tire is installed and used. The side close to the vehicle body and provided with the outer pattern block 14 is away from the vehicle body.

[0054] The first shoulder block 5 is provided with mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com