Band sawing machine with wood dust removal and separation function

A band saw machine and sawdust technology, applied in band saws, separation methods, and dispersed particle separation, etc., can solve problems such as health hazards, wood chips of different sizes, and potential safety hazards, and achieve easy installation, increased service life, and reduced effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

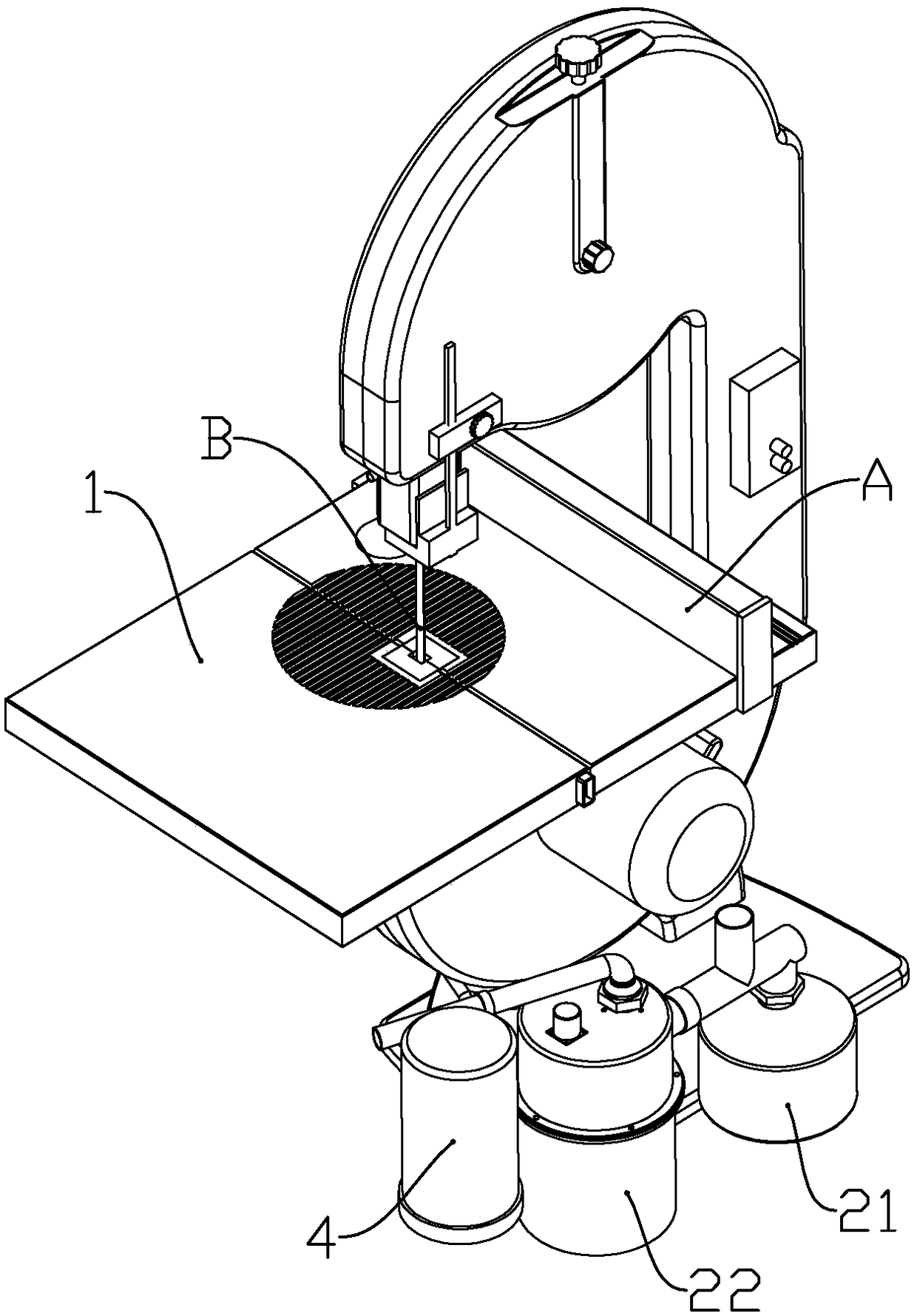

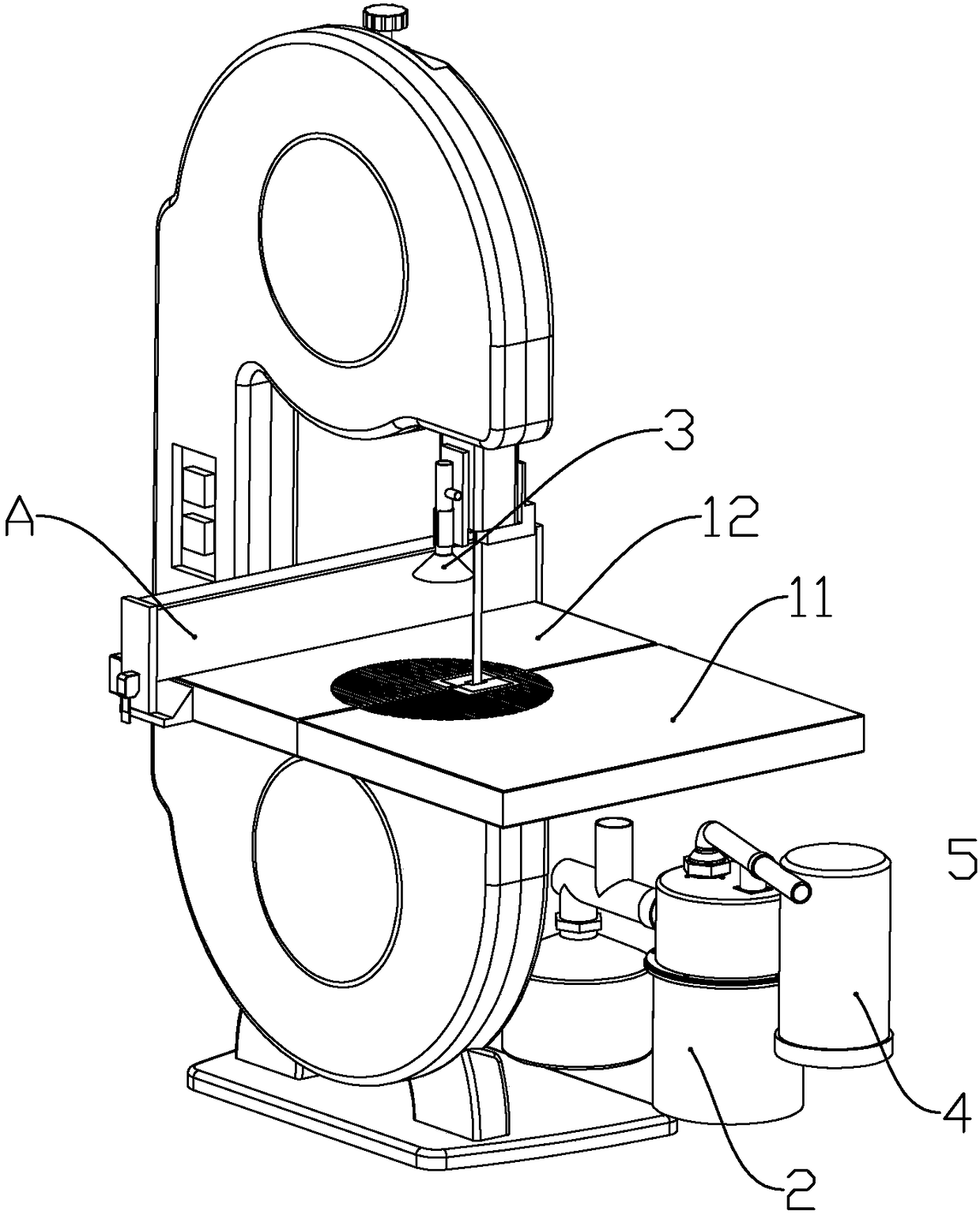

[0047] according to Figure 1 to Figure 13 As shown, a band saw machine capable of cleaning and separating sawdust described in this embodiment includes a body, a workbench 1 installed on the body, a saw band B installed on the body, and a saw band B movably installed on the workbench. The backing A, the dust collection assembly 2 arranged under the workbench, the air duct assembly 3 movably installed on the body, and the compressed air pump 4 respectively connected with the dust collection assembly and the air duct assembly through pipelines.

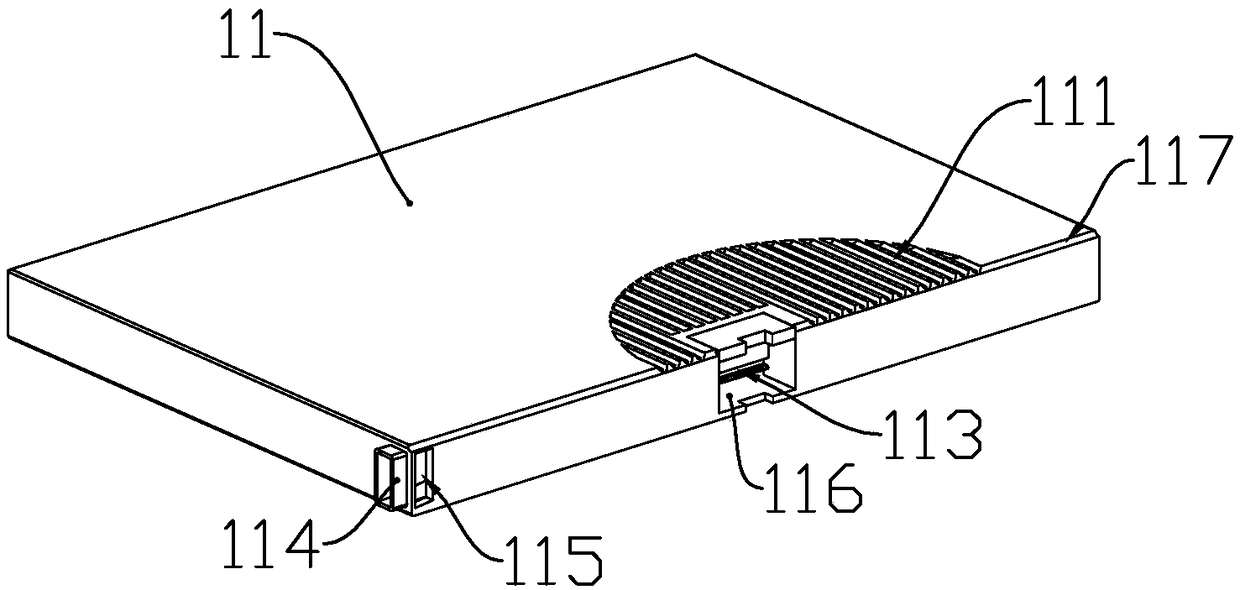

[0048] The workbench includes an outer workbench 11 and an inner workbench 12 fixedly connected to each other; the saw band is located between the outer workbench and the inner workbench; the outer workbench and the inner workbench are both It is hollow; the upper end surface of the inner workbench is formed with a second sawdust inlet 121 for sucking sawdust; the second sawdust suction cavity 122 is formed in the inner workbench below...

Embodiment 2

[0071] combine Figure 14 As shown, this embodiment makes the following improvements to the dust collection assembly on the basis of Embodiment 1: the second filter assembly includes a dust collection cover, a second dust collection cylinder, an inner cylinder, a filter pipe, and an air outlet pipe , the second delivery rod and the second impeller 227 fixedly connected to the upper end of the second delivery rod; the second impeller is coaxial with the second delivery rod; the second impeller is formed corresponding to the horizontal tube A plurality of blades 2271 equidistantly distributed in the circumferential direction; the outlet pipe includes a horizontally arranged horizontal tube 2241; the horizontal tube is arranged along the tangential direction of the blade; The cover body 2242; the inner cavity of the cover communicates with the horizontal tube and is isolated from the outside world.

[0072] When the compressed air pump works, an airflow is generated in the air o...

Embodiment 3

[0074] This embodiment has made the following improvements on the basis of Embodiment 1: the compressed air pump is replaced by a vacuum pump and a compression pump; Road connection; the outlet end of the compression pump is respectively connected with the blowing pipe and the blowing pipe through pipelines.

[0075] The vacuum pump and the compression pump are electrically connected to the controller.

[0076] The negative pressure generated by the vacuum pump sucks the sawdust generated during use into the dust collection assembly, and the compressed air is pumped into the blowing pipe and blowing pipe through the compression pump, and controlled according to the user's needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com