Bearing module and bearing

A technology of bearing components and bearings, applied in the field of machinery, can solve problems such as the impact of bearings that cannot be ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It can be seen from the background art that the bearing cage is prone to fracture when subjected to impact or vibration.

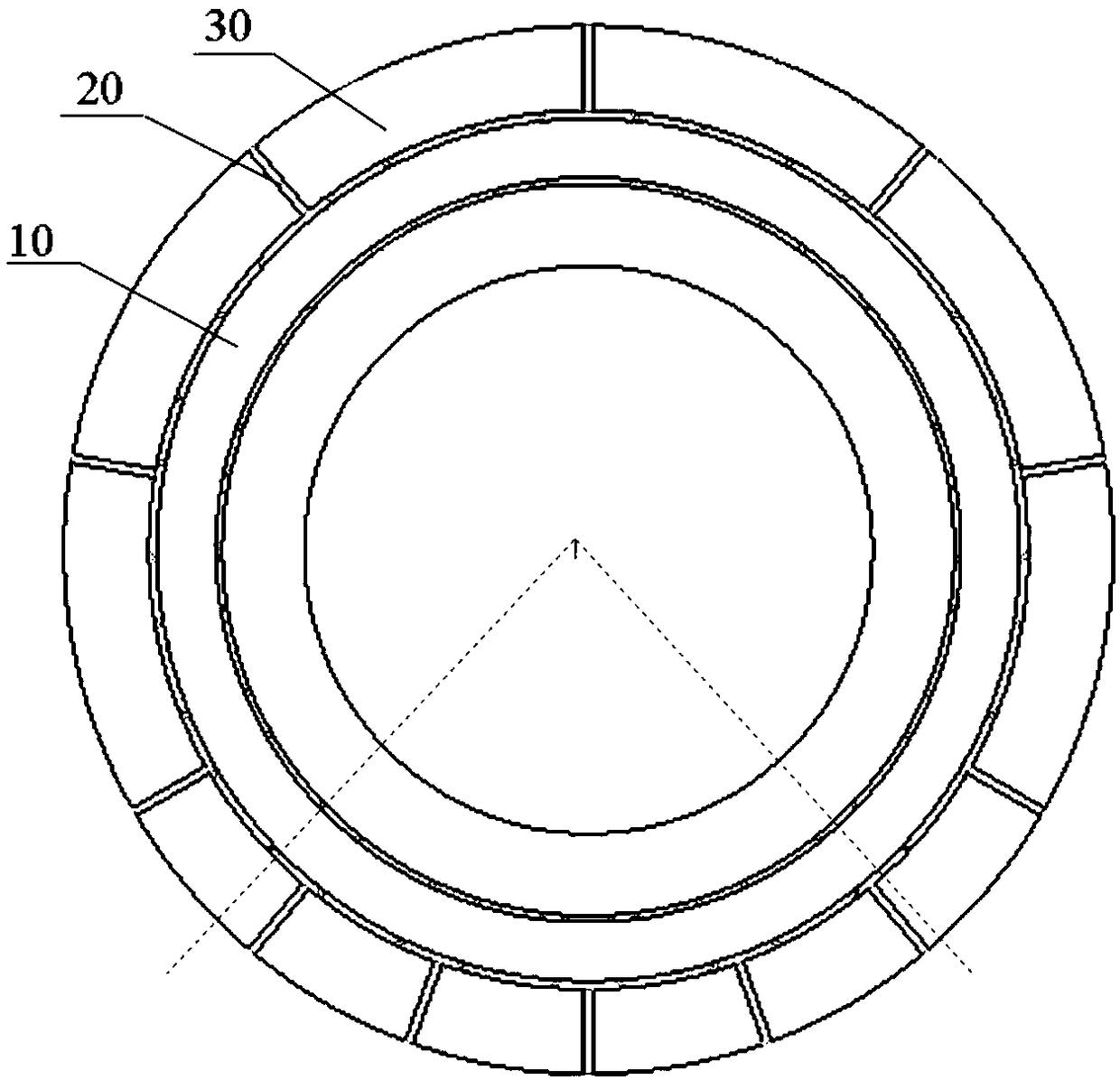

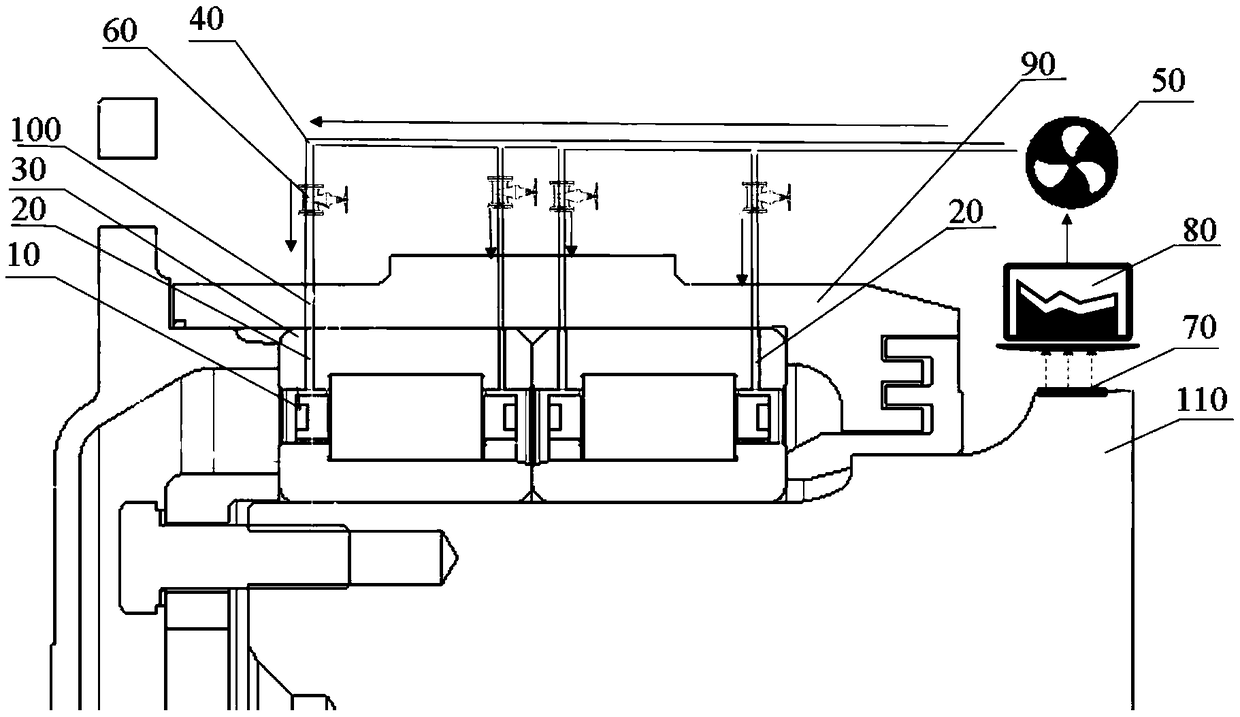

[0030] In order to improve the impact resistance of the bearing, an embodiment of the present invention provides a bearing, which includes a cage and a bearing guide ring; there is a radial gap between the bearing guide ring and the cage, and the bearing guide ring has a There is an air guide hole in the guide ring, the air guide hole in the guide ring communicates with the radial gap and extends to the outer surface of the guide ring of the bearing. During the working process of the bearing, the external air is provided for the bearing through the air source, so that the gas enters the radial gap through the guide ring air guide hole opened on the outer surface of the bearing guide ring, so that the air between the bearing guide ring and the cage A circle of air film is formed to provide support for the cage in the circumferential direction. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com