Linear vibration device for electrolytic machining

A linear vibration and vibration shaft technology, applied in electric machining equipment, electrochemical machining equipment, attachments, etc., can solve the problems of poor buffer damping, complex structure, etc., to reduce frictional resistance, stable and reliable transmission, and meet vibration requirements. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

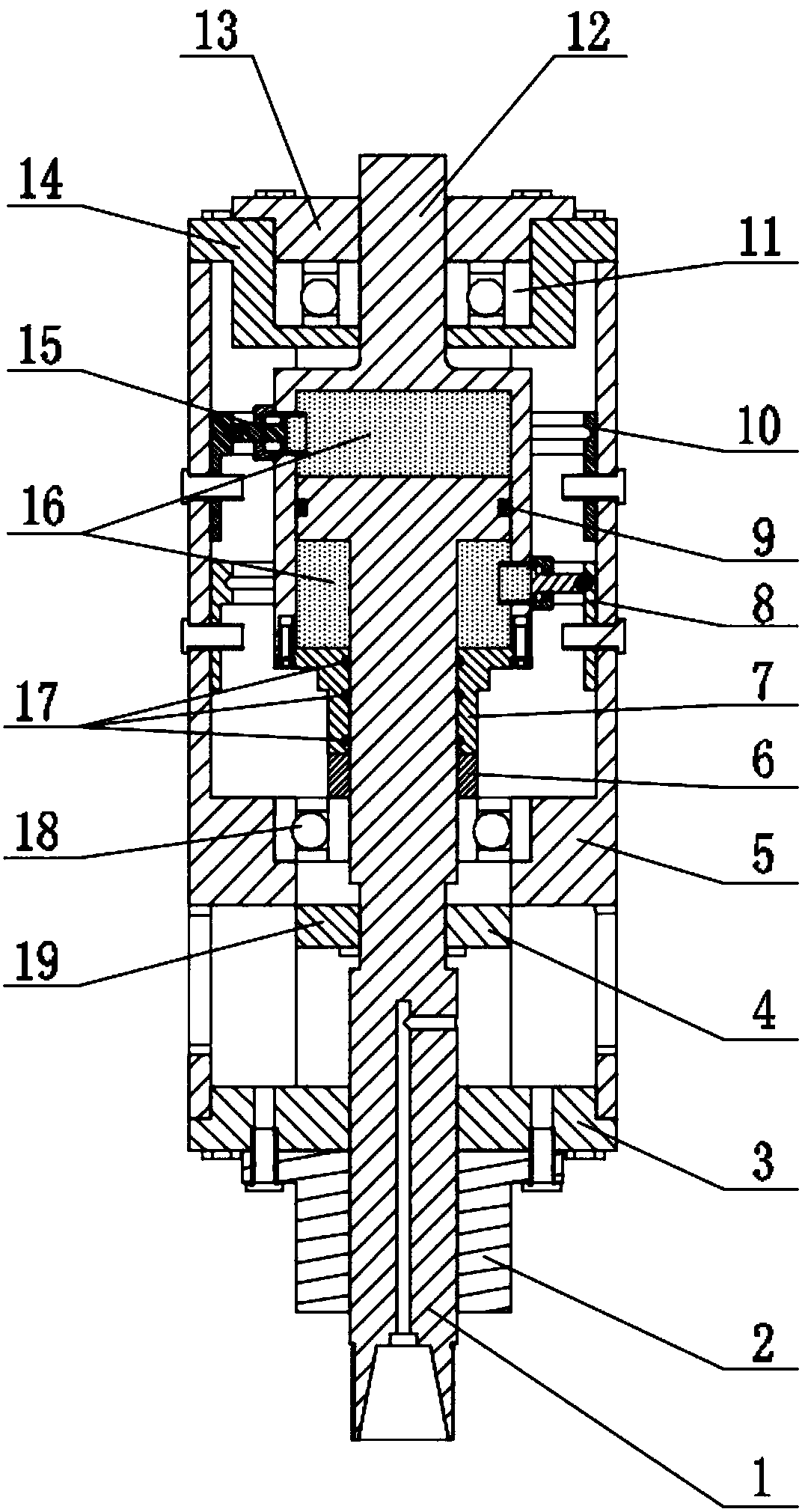

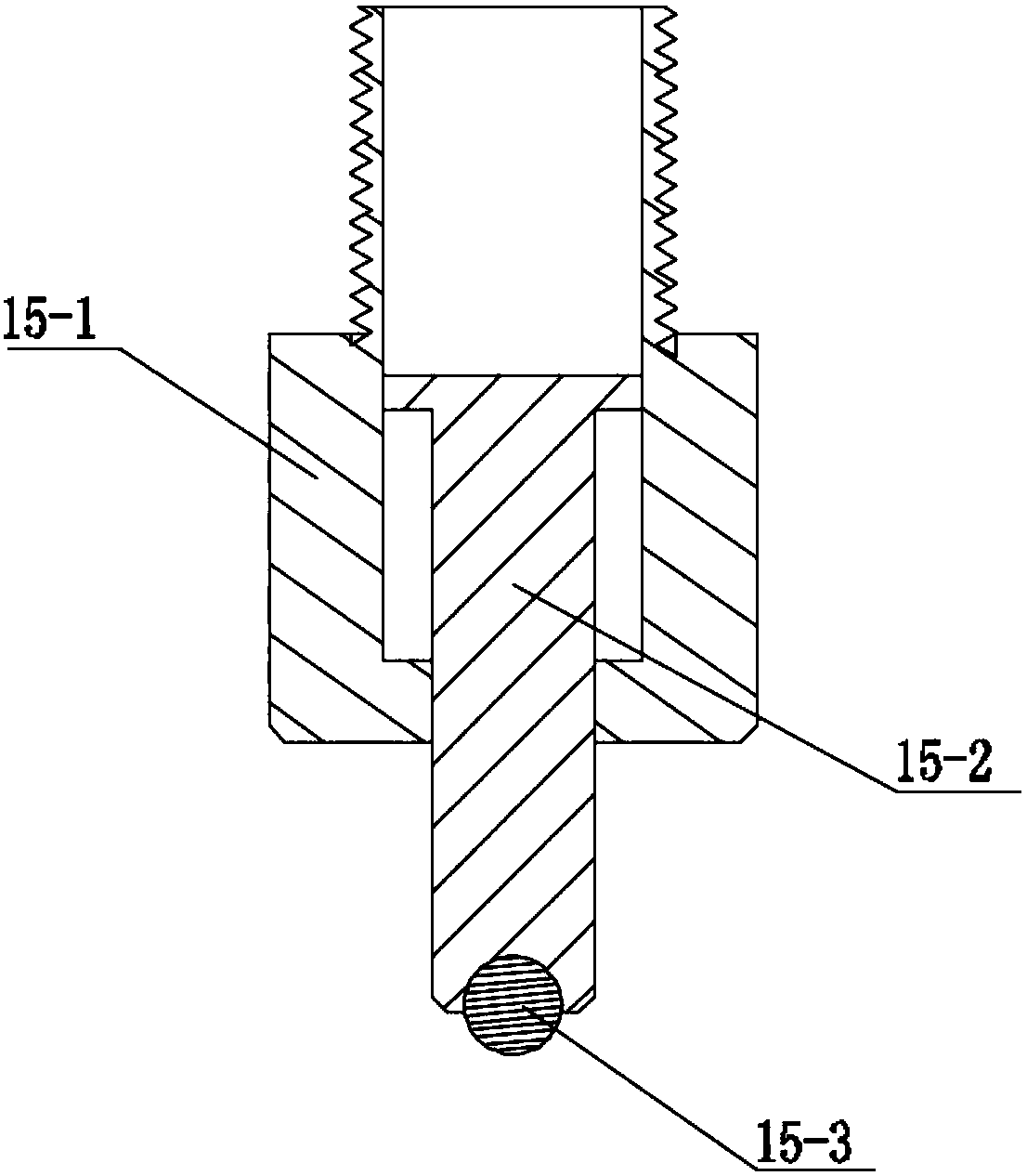

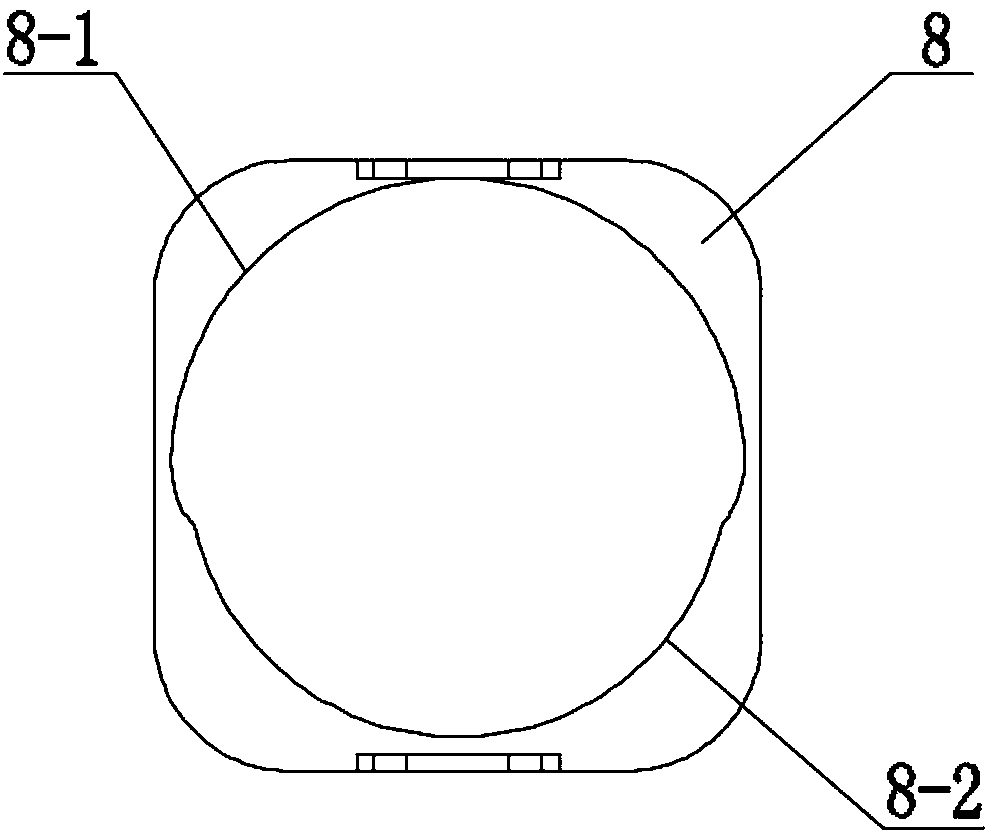

[0035] combinefigure 1 and figure 2 As shown, a linear vibrating device for electrolytic machining in this embodiment includes a box body 5, an input shaft 12, a vibrating shaft 1, a lower cam 8, an upper cam 10 and a small oil cylinder 15, and the box body 5 is used as the main body of the linear vibrating device The input shaft 12 can be connected with an external motor and rotated under the drive of the external motor. The input shaft 12 is rotated and installed in the box body 5, and the vibration shaft 1 and the input shaft 12 are installed coaxially. In the box body 5, and between the vibration shaft 1 and the box body 5 is also provided with a stop structure, one end of the input shaft 12 has a piston cylinder, the piston cylinder can be integrally formed at one end of the input shaft 12, the vibration shaft 1 One end has a piston matched with the above-mentioned piston cylinder, the piston can slide up and down in the piston cylinder, and the piston is also provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com