Integrally-formed arc type milling cutter

An arc and integrated technology, which is applied in the field of arc milling cutters, can solve the problems of lack of cooling devices, etc., achieve the effects of convenient use, avoiding the decrease of structural stability, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

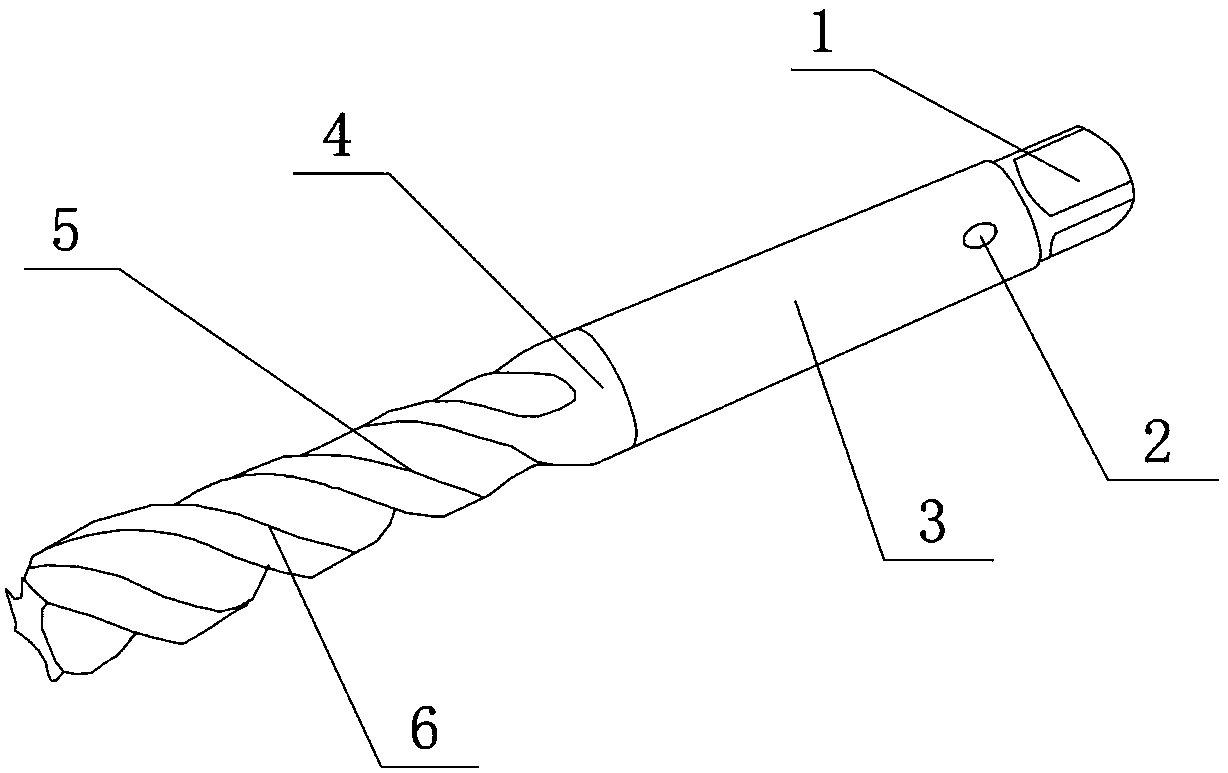

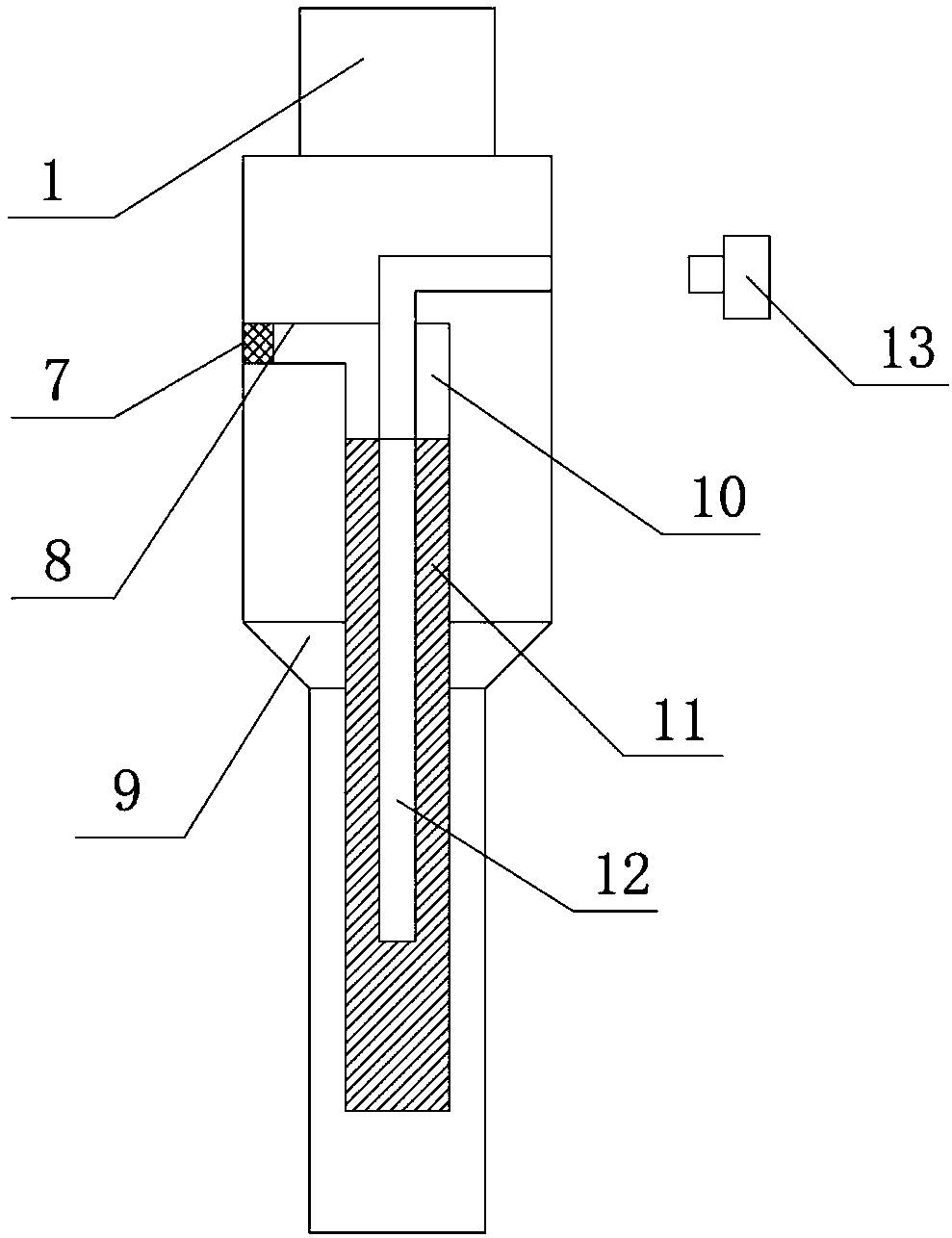

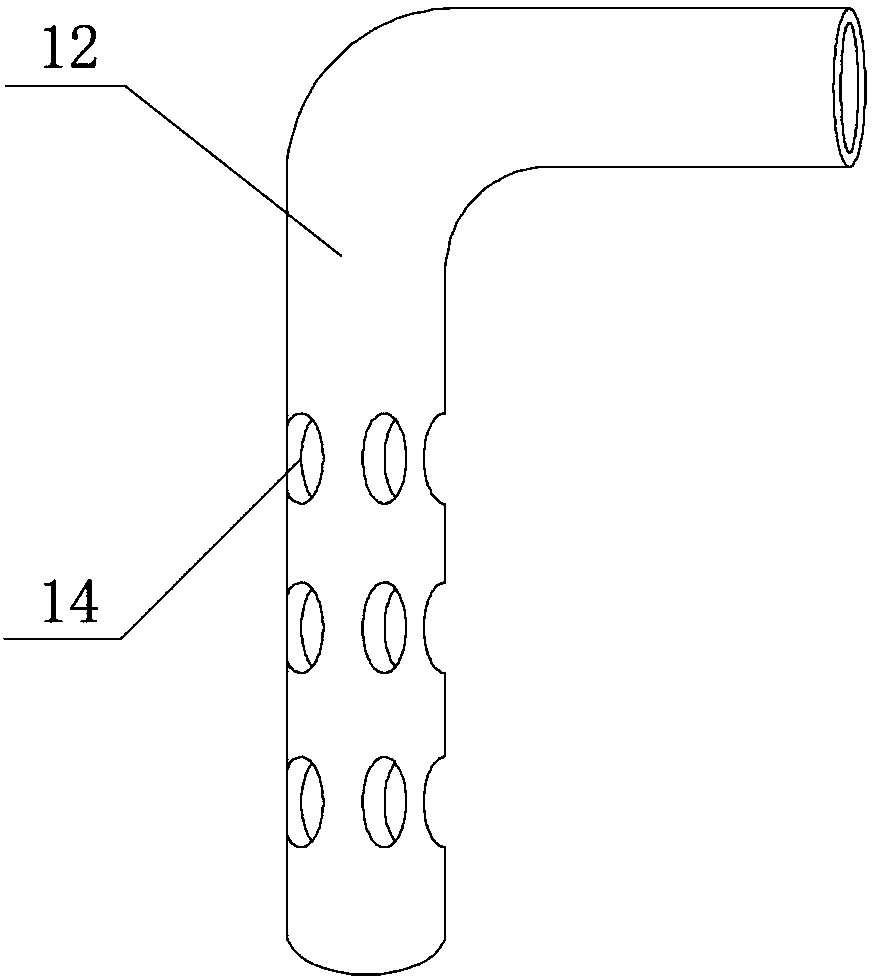

[0021] see Figure 1-4 As shown, an integrally formed arc type milling cutter includes a working head 4, a connecting block 9 is arranged at one end of the working head 4, a connecting rod 3 is arranged at one end of the connecting block 9, and a connecting head 1 is arranged at one end of the connecting rod 3, and the working head 4 is formed by The spiral groove 5 and the cutting edge 6 are composed of a groove 10 inside the connecting rod 3, a sponge layer 11 is arranged inside the groove 10, and an air outlet 8 is arranged on one side of the groove 10, that is, the circular arc milling cutter is discharged through the air outlet 8, and then It can reduce the internal pressure of the arc-type milling cutter, thereby avoiding the decrease of the structural stability of the arc-type milling cutter due to excessive internal pressure of the arc-type milling cutter. Catheter 12, one end of the catheter 12 is provided with a liquid inlet 2, the inside of the liquid inlet 2 is cov...

Embodiment 2

[0023] read on Figure 1-4 , the difference from Example 1 is that the groove 10 runs through the connecting rod 3, the connecting block 9 and the working head 4, and the groove 10 is closely connected with the sponge layer 11, so that the cooling liquid in the sponge layer 11 can be round The arc milling cutter plays the role of cooling. The cover 13 is threadedly connected to the liquid inlet 2 , and the shape of the catheter 12 is L-shaped, thereby preventing external dust from entering the catheter 12 from the liquid inlet 2 . The shape of the connecting block 9 is a truncated cone, and the connecting block 9 is fixedly connected with the connecting rod 3 and the working head 4, so that the stress concentration between the working head 4 and the connecting rod 3 can be reduced, and the circle can be improved. The service life of the arc milling cutter. The helical grooves 5 and the cutting edges 6 are alternately arranged, and the direction of rotation of the cutting edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com