Warm forging forming technology of plum coupling

A plum-blossom coupling and forming process technology, applied to engine components, mechanical equipment, etc., can solve problems that threaten the life safety of equipment operators, claws break and fly out, etc., and achieve improved organizational structure and mechanical properties, metal flow, etc. The effect of line integrity, improving plasticity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

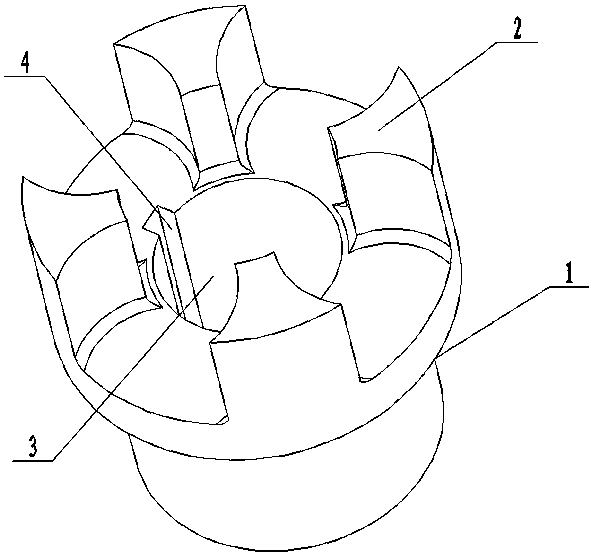

[0013] Such as figure 1 As shown, the warm forging forming process of the plum blossom coupling includes the following process steps: material selection for the driving shaft coupling 1, blanking, shot blasting, heating, upsetting the head of the driving shaft coupling 1, and The shaft coupling 1 is back-extruded to obtain figure 1 The driving shaft coupling 1 of the shape shown, four driving coupling jaws 2 are formed on the upper end of the driving shaft coupling 1, and the driving shaft coupling shaft hole 3 and the driving coupling shaft hole 3 are formed inside the driving shaft coupling 1. Shaft device keyway 4, get long, get driving shaft coupling forging.

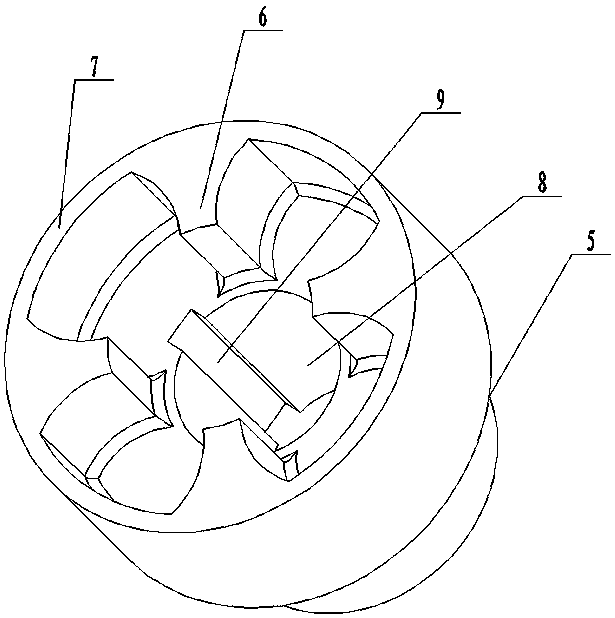

[0014] Material selection, blanking, shot blasting, heating, upsetting the head of the driven shaft coupling 5, and back-extruding the driven shaft coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com