Car door sliding rail stretch bending machine

A technology of stretch bender and slide rail, which is applied in the field of auto parts processing, can solve the problems of difficult bending in the vertical and horizontal directions, low qualified rate of slide rail finished products, low production efficiency, etc., to ensure cutting effect, convenient positioning, and the effect of improving swing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

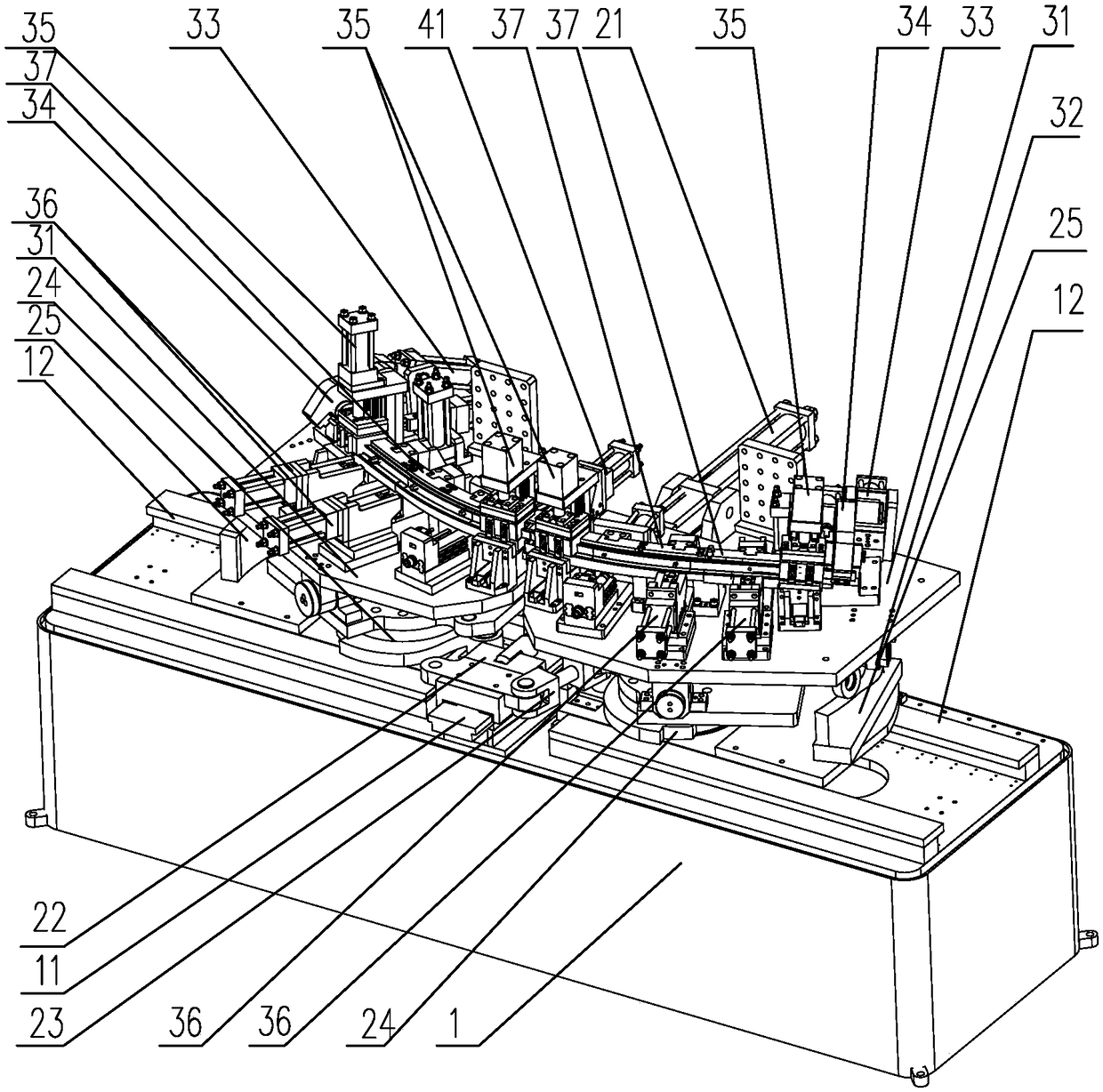

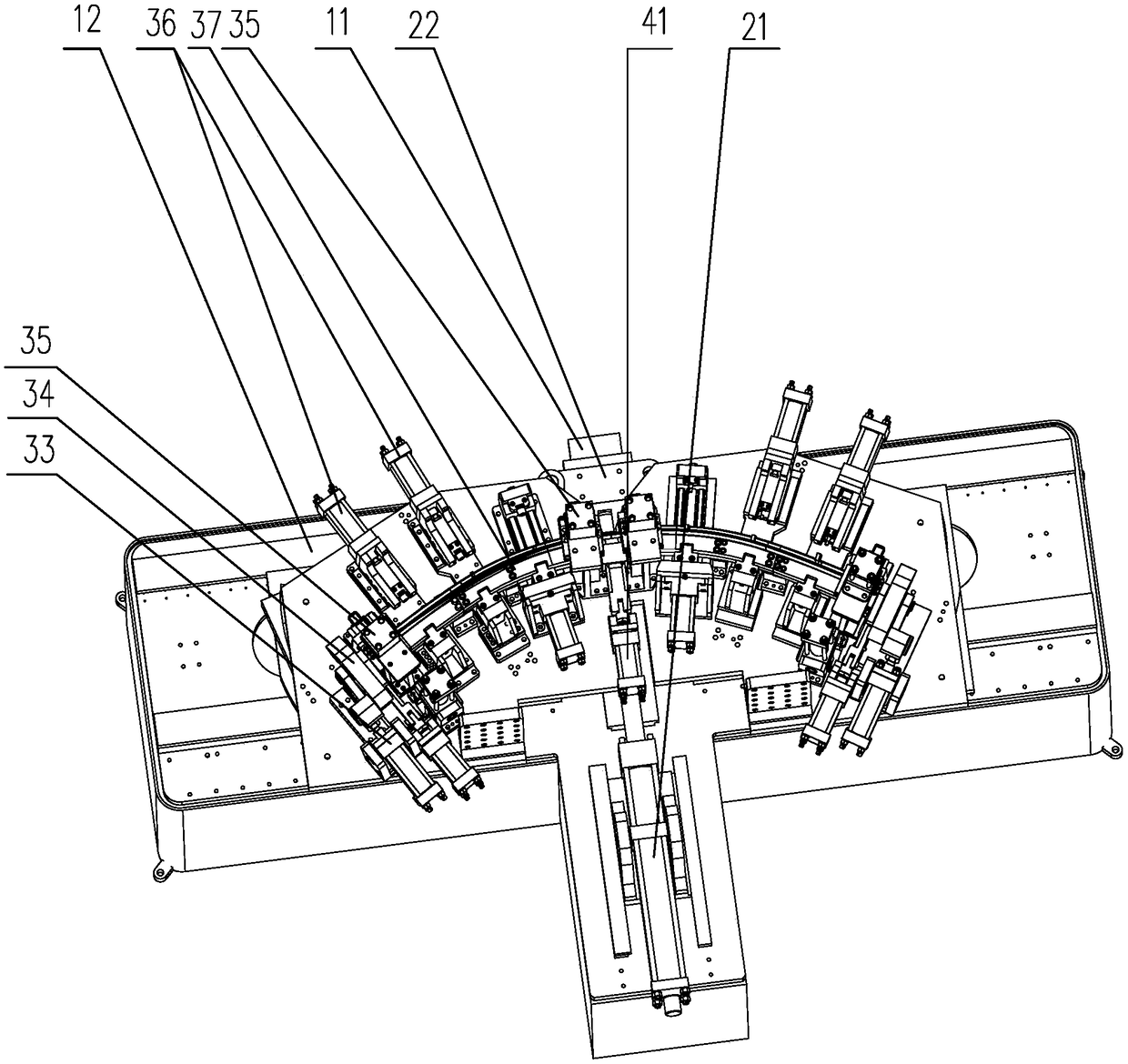

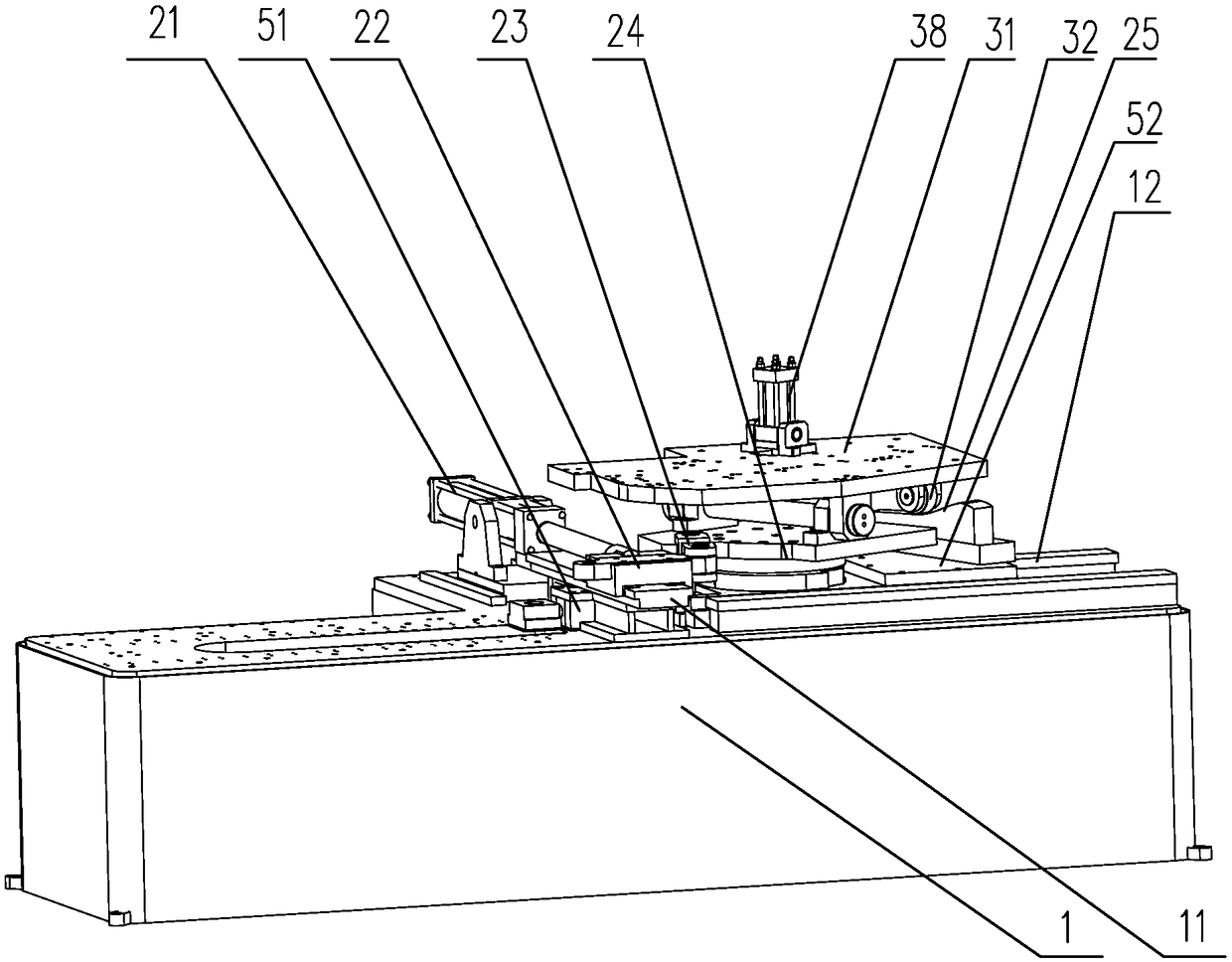

[0028] Depend on Figure 1 to Figure 6It can be seen that the present invention discloses a car door slide rail stretch bending machine, which includes a bracket 1, and two groups of stretch bending devices are mirrored on the bracket 1, and the stretch bending devices include a movable platform 31 and a motor for driving the movable platform. 31 movement drive mechanism, the movable platform 31 is movably arranged on the support 1, and the movable platform 31 is provided with a loading track 37, and the described loading track 37 is arranged in an arc shape, and the movable platform 31 is provided with a useful The positioning device is used to fix the material on the loading track 37. The positioning device includes a pressing mechanism for positioning the two ends of the door slide rail and a fixing mechanism for fixing the main body of the door slide rail. The pressing mechanism includes a pressing member 34 and a first pressing cylinder 33 which is obliquely arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com