Combined CO2 laser tube

A laser tube and combined technology, applied in the field of CO2 laser tube, can solve the problems of difficulty in outputting higher power and poor stability, and achieve the effects of not easy to deform, improve stability, and increase laser power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

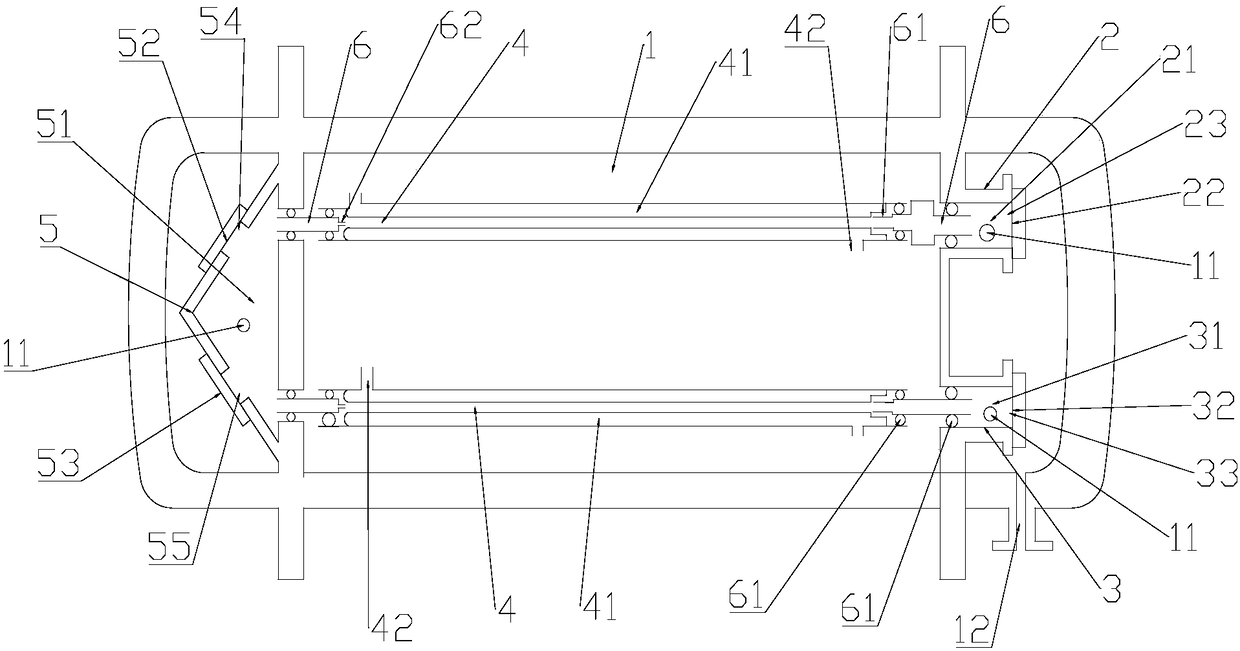

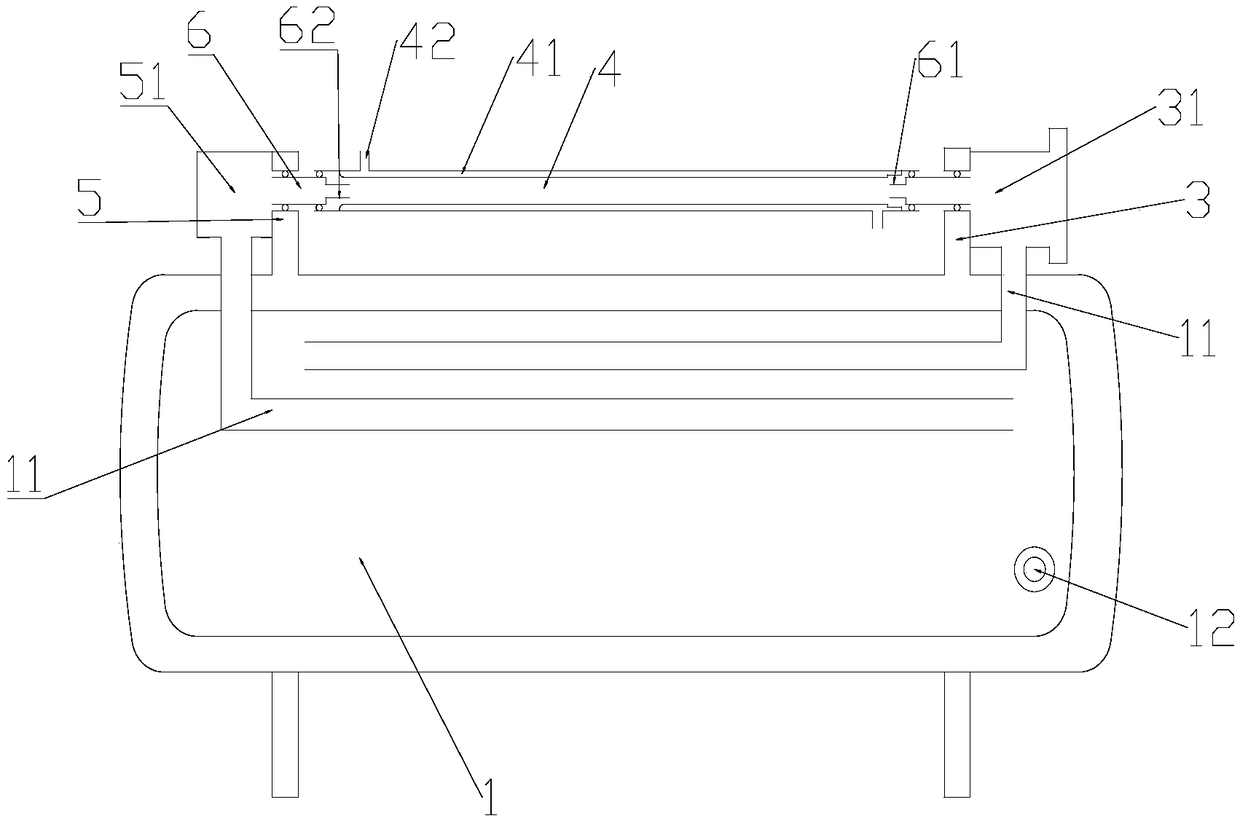

[0013] The present invention will be further described now in conjunction with accompanying drawing.

[0014] Such as Figure 1-2 As shown, a combined CO 2 The laser tube includes a gas storage tube 1, the gas storage tube 1 is provided with a total reflection mirror seat 2 and a window mirror seat 3, the total reflection mirror seat 2 has a total reflection cavity 21, and the window mirror seat 3 has a window cavity 31, The total reflection cavity 21 and the window cavity 31 are communicated through a number of discharge tubes 4 which are connected end to end in sequence, and a turn-back mirror seat 5 is arranged between two adjacent discharge tubes 4, and the turn-back mirror seat 5 has a turn-back cavity 51, and in the turn-back cavity 51 A first reflector 52 and a second reflector 53 are installed, the first reflector 52 cooperates with the second reflector 53 to reflect the laser emitted from the previous discharge tube 4 to the next discharge tube 4, and the total refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com