Ironing auxiliary device and stitch adjusting mechanism

The technology of an auxiliary device and an adjustment method, which is applied in the field of ironing, can solve problems such as poor straightness and aesthetics of clothes, non-standard midline, secondary wrinkles of clothes, etc., and achieve good straightness and aesthetics, and good ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

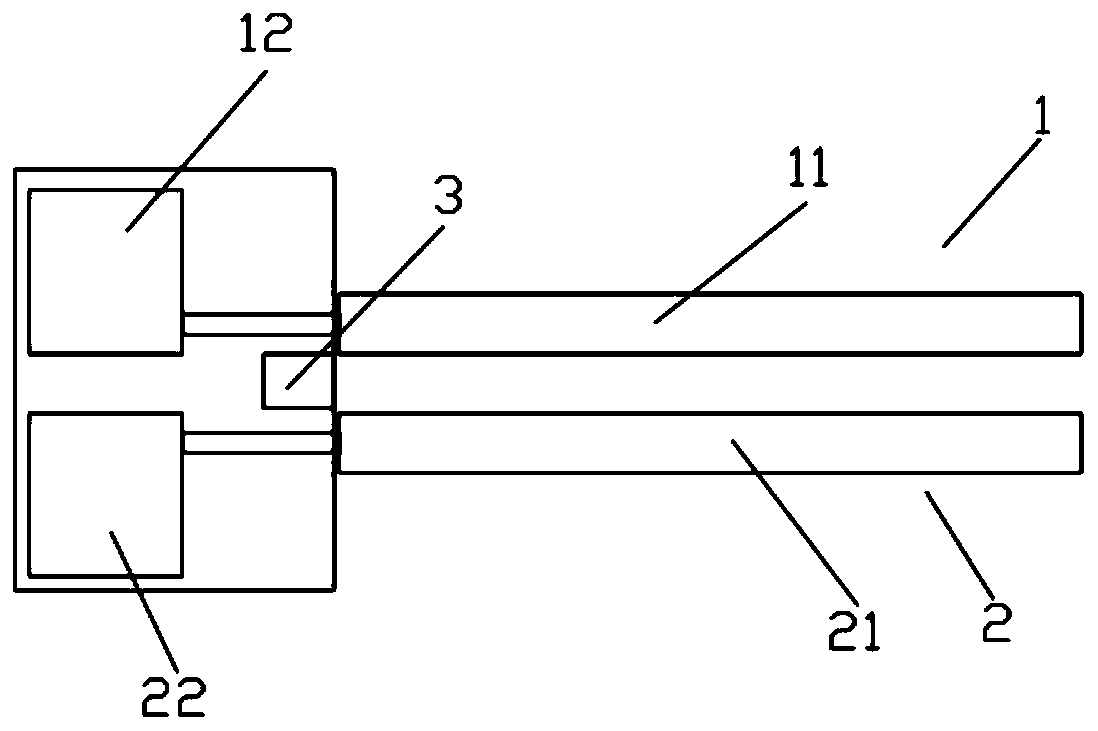

[0033] like figure 1 As shown, the ironing auxiliary device includes a first rubbing assembly 1 , a second rubbing assembly 2 and a detection assembly 3 . The first rubbing assembly 1 and the second rubbing assembly 2 can move in two opposite directions respectively, and respectively drive the cloth on the front and rear sides of the clothes to move in two opposite directions to achieve the effect of rubbing. In addition, the ironing auxiliary device can be used as a clamp, the first rubbing assembly 1 and the second rubbing assembly 3 can clamp the clothes fabric in the middle, and the first rubbing assembly 1 and the second rubbing assembly 2 go to the same Direction movement realizes straightening and flattening of clothes, and two or more auxiliary ironing devices can be used at the same time to clamp two or more points at both ends of the cloth of the clothes, so that the clothes can be straightened and flattened better. The detection component 3 confirms the initial pos...

Embodiment 2

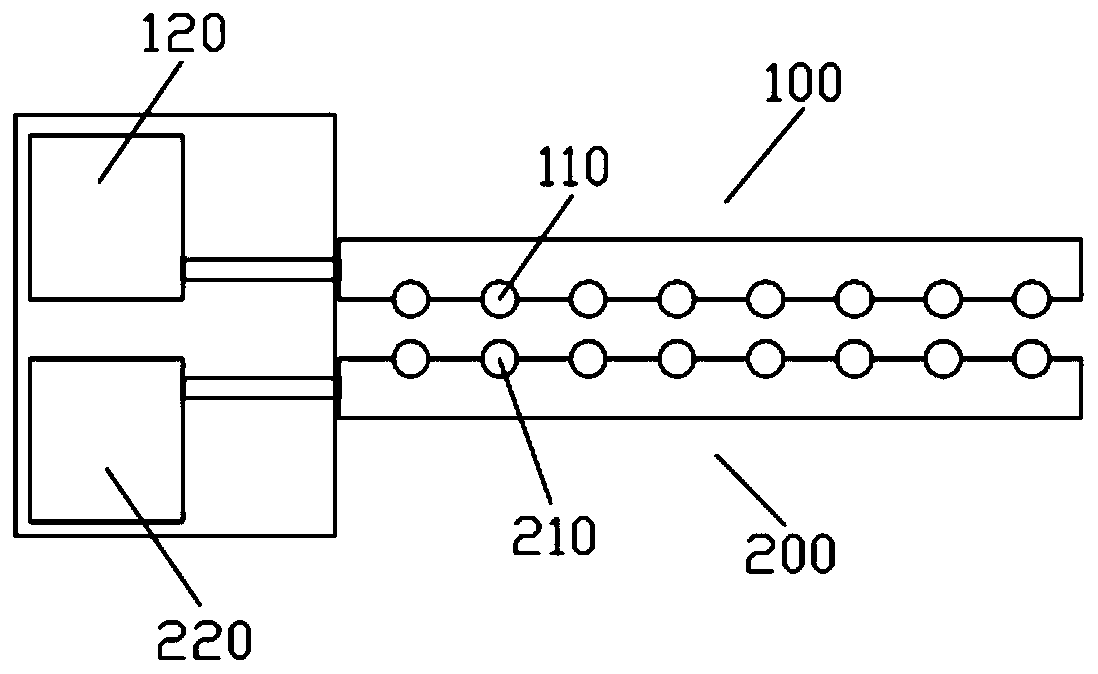

[0037] The difference between this embodiment and embodiment 1 is that, as figure 2 As shown, the first rubbing assembly 100 includes a plurality of first rollers 110 and a first rotation driving device 120 that drives a plurality of first rollers 110 to rotate together, and the second rubbing assembly 200 includes a plurality of second rollers 210 and drives multiple A second rotary drive device 220 that rotates together with a second roller 210. The first roller 110 and the second roller 210 respectively contact the front and rear sides of the clothes and sandwich the clothes between the two rollers 110, 210, the first rotation driving device 120 drives the first roller 110 to rotate, and the second rotation driving device 220 drives The second roller 210 rotates, and the rotation directions of the first roller 110 and the second roller 210 are opposite, thereby driving the fabrics on the front two sides of the clothes to move in two different directions to realize the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com