A tool management method

A tool management and tool technology, applied in the direction of data processing applications, instruments, calculations, etc., can solve the comprehensive management, tool cost reduction, and optimization of the entire life cycle that does not fully cover tool demand analysis and testing, warehouse management, tool pre-adjustment, and on-site use. Difficult to find a breakthrough, lack of scientific and reasonable management of tool life, etc., to achieve the effect of reducing quality hidden dangers, minimizing tool inventory, and reliable tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to make the object, beneficial effect and technical solution of the present invention clearer, the method of the present invention will be introduced below through the management process of the tool A in the tool management system (TMS).

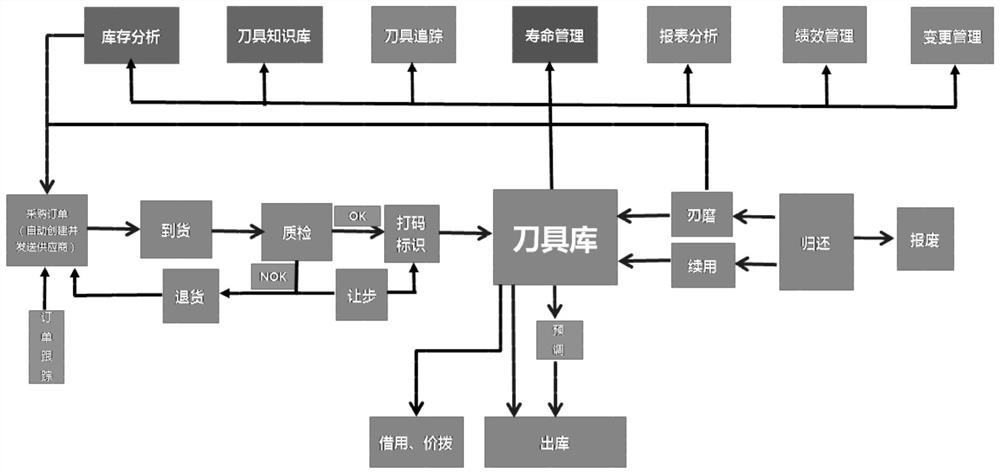

[0064] Such as figure 1 As shown, the present invention is based on the overall architecture of TMS, comprising the following steps:

[0065] 1. Basic data entry

[0066] 1) Maintain the properties of tool A in TMS, including tool code, name, material category, spare part type, cutting parameters, inspection standards, tool diagram, tool material, tool life attribute, procurement cycle, supplier, price and other information;

[0067] 2) Maintain basic information such as production lines, equipment, products, tool suppliers, warehouse locations, organizational structures, quality inspection standards, measurement units, mail systems, and user permissions;

[0068] 3), maintenance process route. Maintain the process route o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com