Parameter inversion method of probability integral method based on quantum annealing method

A probabilistic integration method and parameter inversion technology, applied in the field of mine deformation monitoring, can solve the problems of poor reliability of probabilistic integration parameters, slow convergence speed, and reduced accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

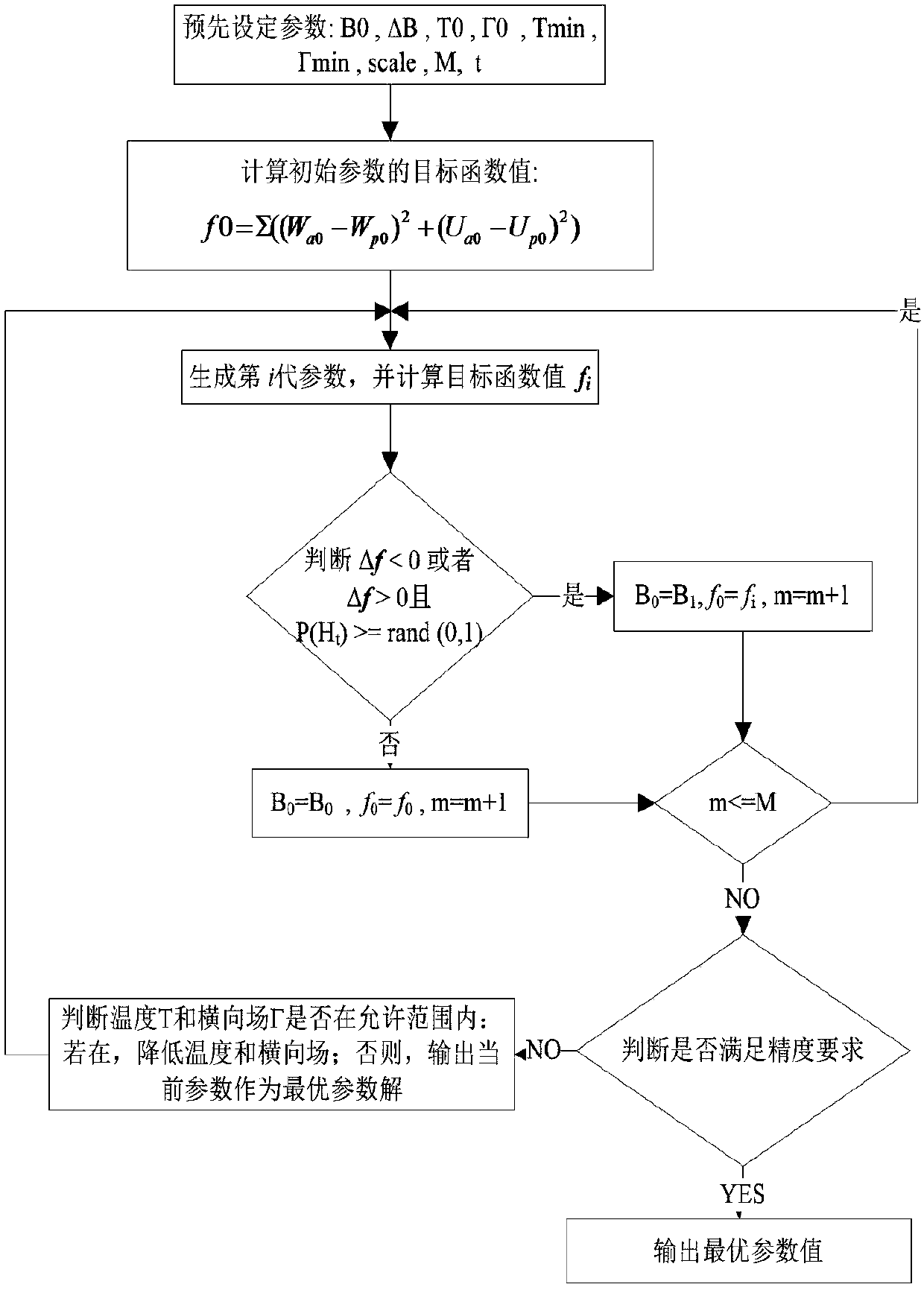

[0019] Example 1, such as figure 1 As shown, a parameter inversion method of the probability integration method based on the quantum annealing method is given, including the following steps:

[0020] Assume that the subsidence and horizontal movement measured at the surface movement observation point above the working face are respectively W ai , U ai , the predicted subsidence value and horizontal movement value of the observation point at the i-th iteration are respectively W pi , U pi , taking the minimum sum of squares of the difference between the predicted value and the observed value as the criterion, the energy in a certain state is calculated as,

[0021] E. i = f i =Σ((Wp i -Wa i ) 2 +(Up i -Ua i ) 2 )

[0022] Then the Hamilton quantity under no external force in quantum annealing is,

[0023] h 0 =E i+1 -E i = f i+1 -f i

[0024] Step 1. Preset the initial value of the probability integral parameter B 0 , temperature and transverse field variati...

Embodiment 2

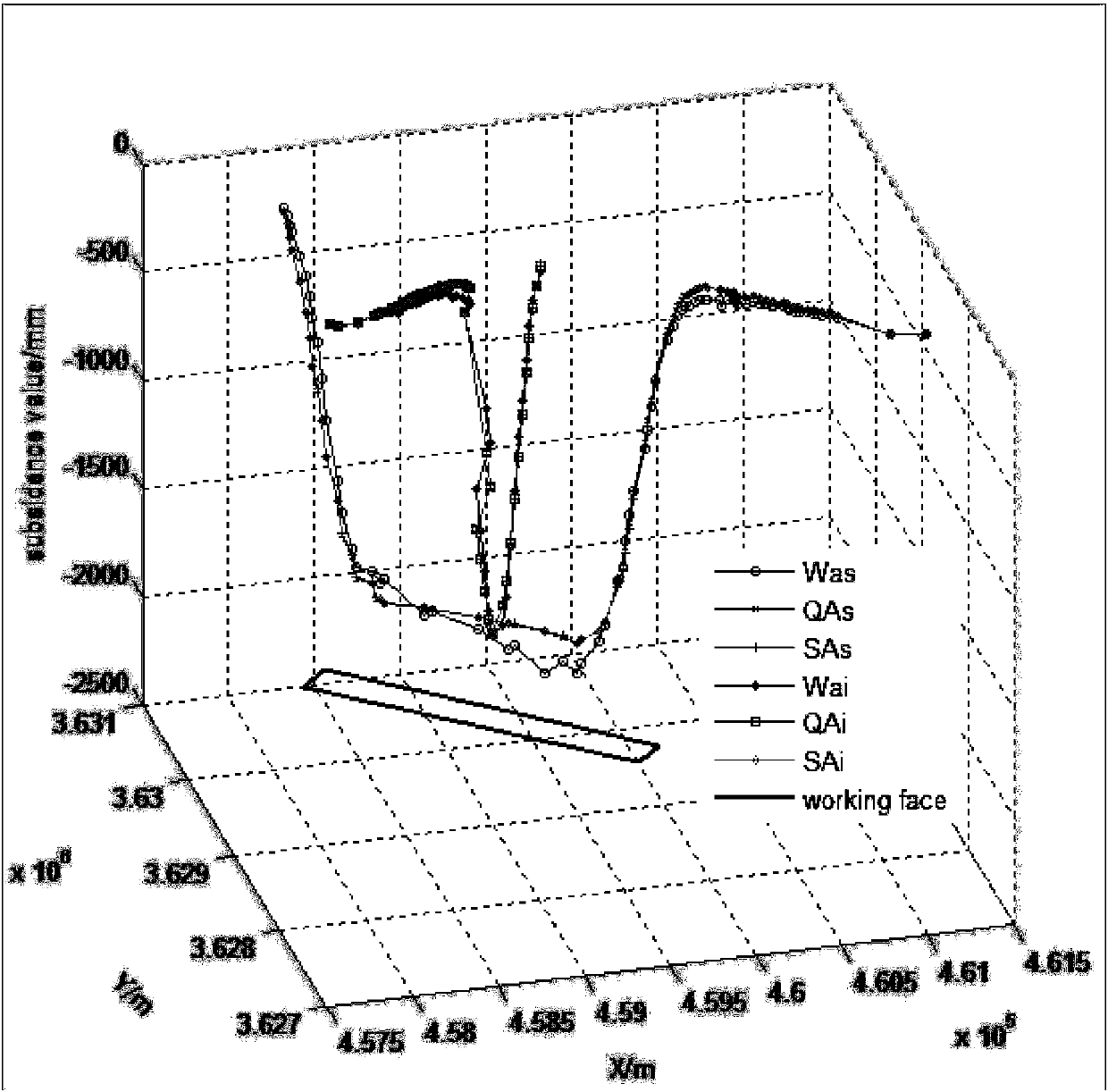

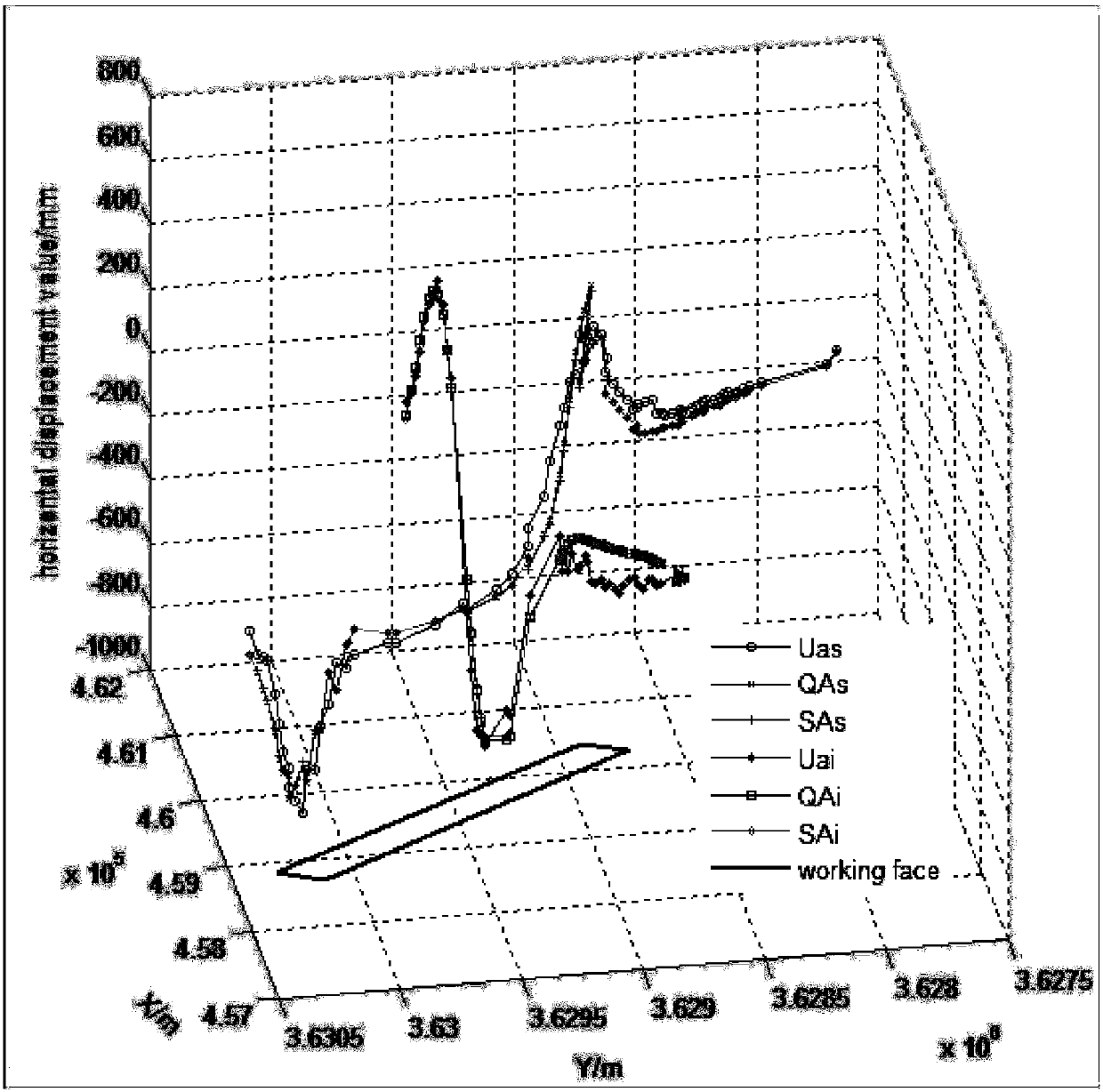

[0032] The 1414 (1) working face of Guqiao Coal Mine in Huainan Mining Area adopts comprehensive mechanized coal mining, mining full height at one time, and managing the roof by the whole caving method, and the working face recovery time is 343 days. The working face is arranged along the direction of the coal seam, the mining size is 2120m×251m (the direction of the working face is full mining, the tendency is not full mining, and the overall mining is not full mining)), the average mining height is 3.0m, and the average inclination angle of the coal seam is 5°. The average buried depth of the working face is 735m. The inclination observation line is arranged at 1144m and 976m from the cutting hole and stop production line, and a total of 3 control points and 50 monitoring points are arranged with a point spacing of 30m and a length of 1500m inclination line. The trend observation line is set at a distance of 39m away from the center line of the working face in the downhill d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com