Measurement method of heat release rate in a ventilated confined space based on three-zone oxygen consumption method

A technology of heat release rate and limited space, applied in the direction of thermal development of materials, can solve the problems of uneven distribution and unreliability of flue gas, and achieve the effect of reducing consumables and simplifying the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] Other structures of this embodiment are the same as those of Embodiment 1 except the following features:

[0067] In this embodiment, the fire source of the combustion test is located at the bottom of the wall, and the fuel is methanol oil pool.

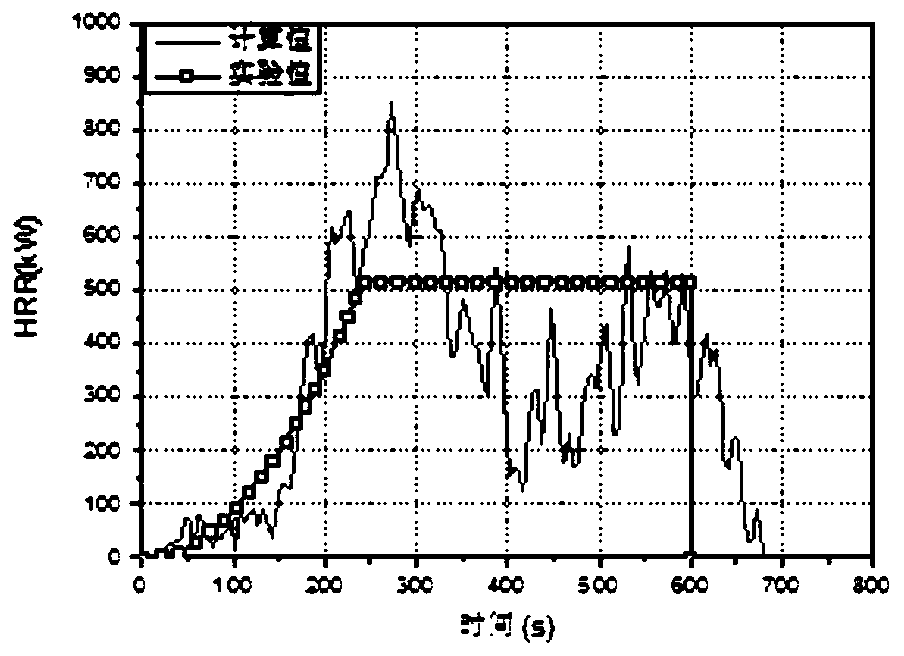

[0068] The comparison between the calculated value of the heat release rate in this embodiment and the experimental value of actual combustion figure 2 shown.

Embodiment 3

[0070] Other structures of this embodiment are the same as those of Embodiment 1 except the following features:

[0071] In this embodiment, the fire source of the combustion test is located beside the wall, and the fuel is PMMA solid.

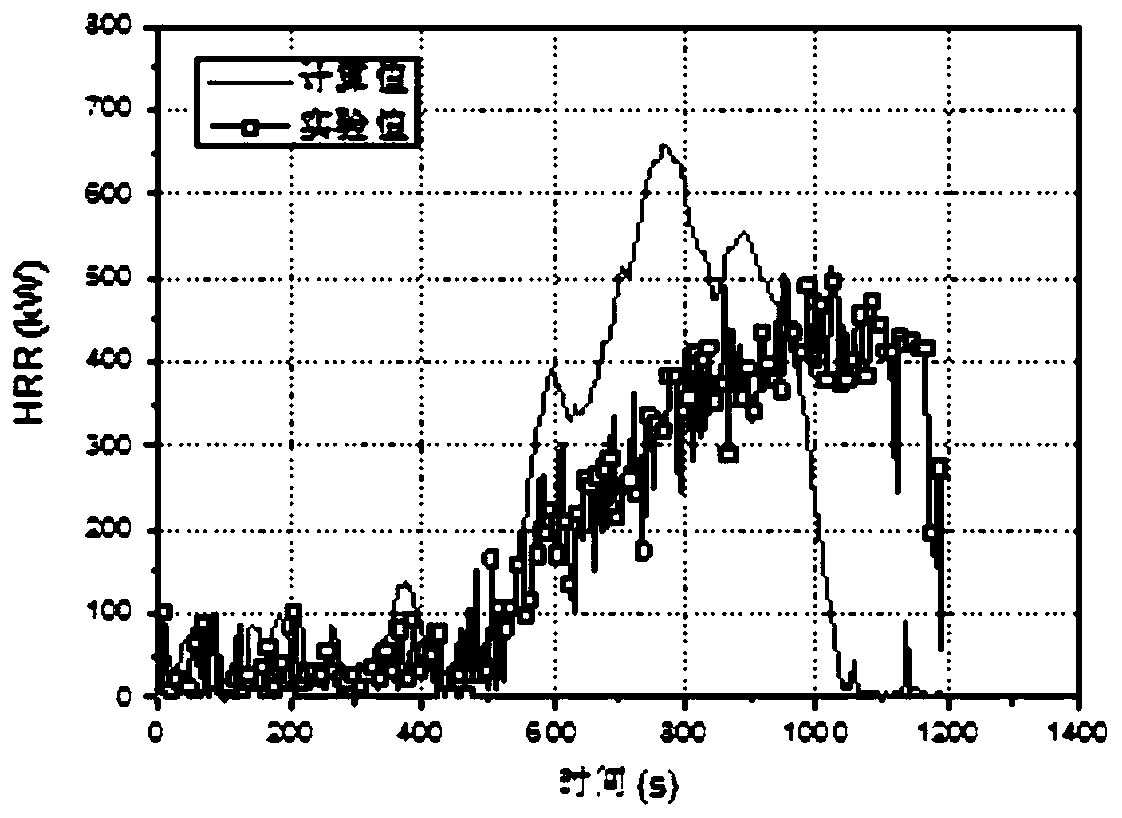

[0072] The comparison between the calculated value of the heat release rate in this embodiment and the experimental value of actual combustion image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com