Swelling positioning detection tool for detecting perpendicularity of casing pipe type product and detection method

A technology of positioning detection and verticality, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of different detection tooling structures and principles, so as to save development and manufacturing costs, improve detection efficiency, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

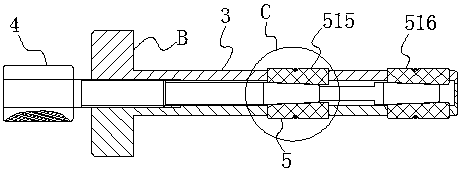

[0042] Embodiment 1: as figure 2 and image 3 As shown, an expansion positioning detection tool for the verticality detection of casing products, which includes an outer sleeve 3 with a detection reference plane B and a conical expansion pin 4 arranged inside the outer sleeve 3, the conical expansion pin 4 can move back and forth inside the outer sleeve 3 along the axial direction of the outer sleeve 3, the central axis of the outer sleeve 3 coincides with the central axis of the tapered expansion pin 4, and there are holes on the peripheral surface of the outer sleeve 3 A plurality of through slots, each of which is provided with a movable wedge 5; during detection, after the outer sleeve 3 is inserted into the casing product 1, the tapered expansion pin 4 is pushed out along the axial direction of the outer sleeve 3. The inner movement of the sleeve uses the cooperation of the tapered expansion pin 4 and the movable wedge 5 to drive the movable wedge 5 to move and protrude...

Embodiment 2

[0054] Embodiment 2: as Figure 9 and Figure 10 As shown, the plurality of through grooves 6 of the outer sleeve 3 are all tapered through grooves, and the movable wedge is trapezoidal, and the upper bottom edge 511 and the lower bottom edge 412 of the trapezoidal movable wedge are hypotenuses, and the ladder One side waist of the shape movable wedge is a straight edge, and the other side waist of the trapezoidal movable wedge is a hypotenuse; Utilize the tapered through groove 6 and the inclined upper base and the inclined lower bottom of the trapezoidal movable wedge 5 Edge fit, so that multiple trapezoidal movable wedges 5 are limited in multiple tapered through grooves 6 on the outer sleeve; when testing, use the inclined waist of the trapezoidal movable wedge and the cone of the tapered expansion pin The surface is in contact with each other, and the straight waist of the trapezoidal movable wedge is in contact with the inner peripheral surface of the casing product. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com