Composite wall for passive ultra-low energy buildings

A technology for composite walls and buildings, applied in passive houses, buildings, building components, etc., can solve the problems of high maintenance and operation costs, unsatisfactory application effects, etc., reduce operation and use costs, improve energy transfer efficiency, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

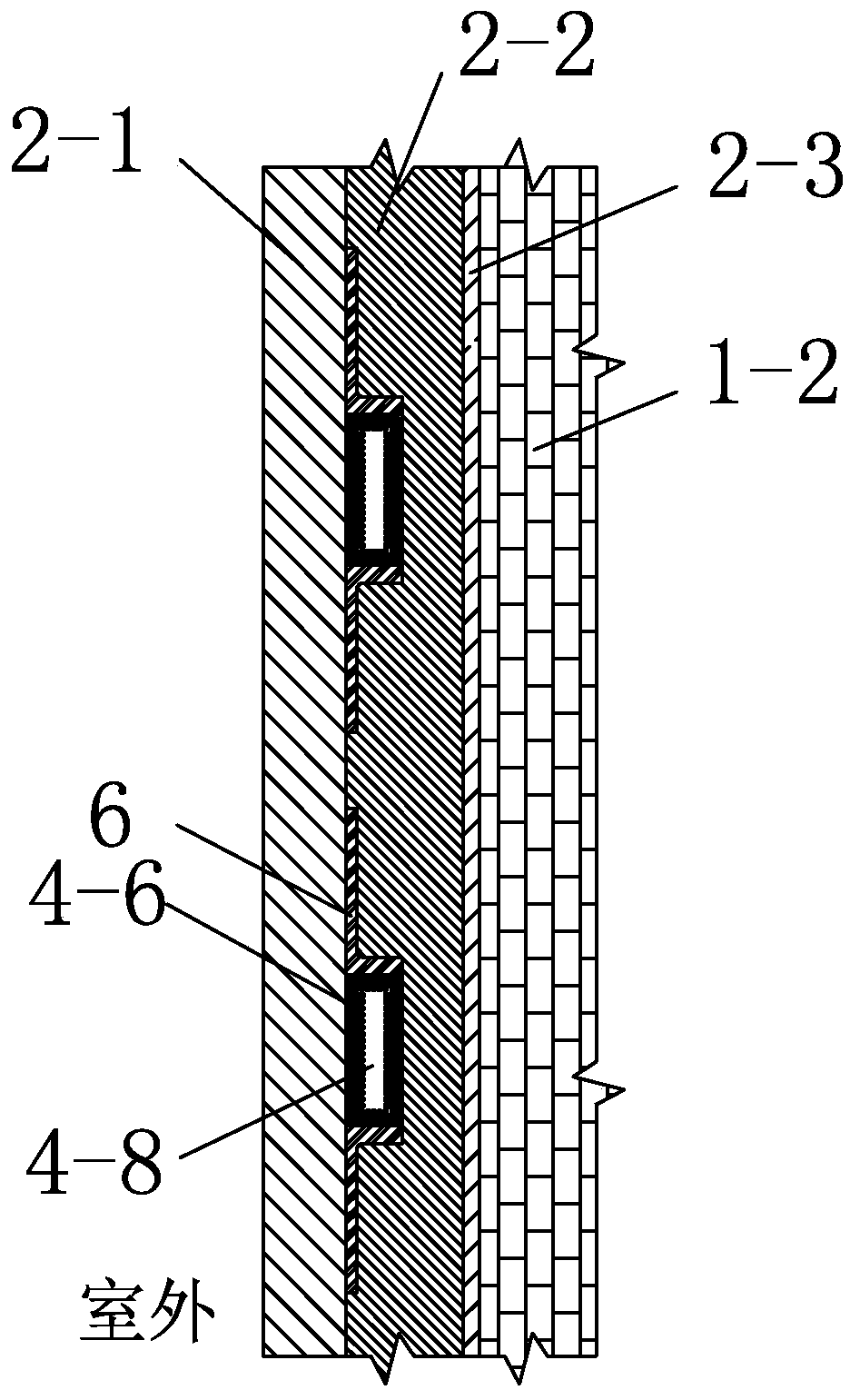

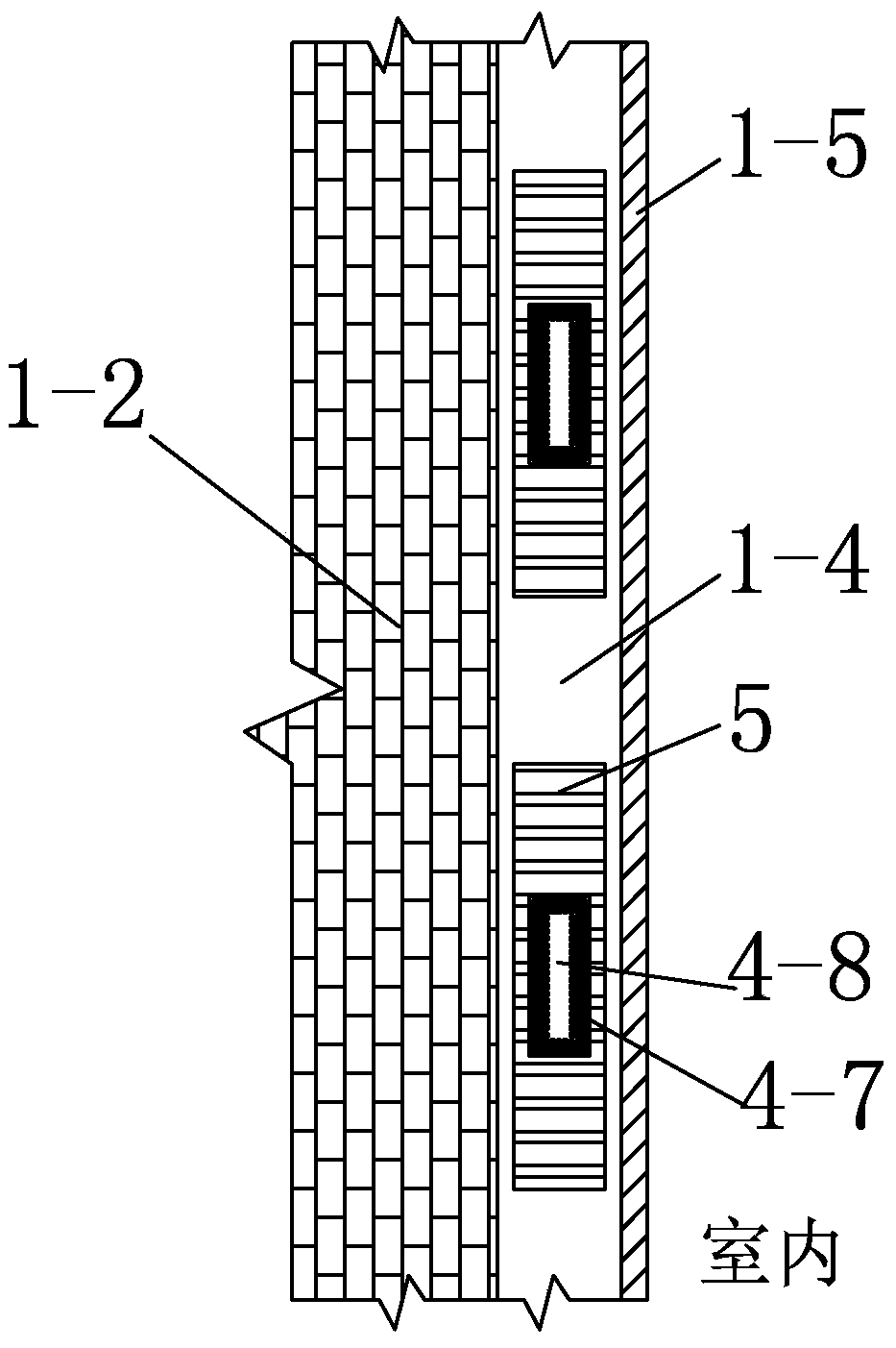

[0026] The schematic diagram of the composite wall for passive ultra-low energy consumption buildings of the present invention is as follows Figure 1-Figure 3 As shown, it includes a composite wall 1 , an outer wall member 2 and a plurality of loop heat pipe units. The composite wall 1 is sequentially composed of an external plastering layer 1-1, a wall insulation layer 1-2, a foundation wall 1-3, an energy storage layer 1-4, and an internal plastering layer from outdoor to indoor. 1-5. The outer wall member 2 is inlaid and fixed on the outer wall plastering layer 1-1 and the wall insulation layer 1-2. The outer member of the wall is a photovoltaic module 2-1, a member insulation layer 2-2 and a substrate 2-3, which are integrated from the outside to the inside. Each loop heat pipe unit includes a closed circulation pipeline composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com