Seam test on a fuel injection pump, and fuel injection pump required for applying same

An inspection method and technology of fuel injection pumps, applied to fuel injection pumps, liquid tightness measurement using liquid/vacuum degree, fuel injection devices, etc., can solve problems such as hindering inspections, short circuits, etc., and achieve the effect of increasing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

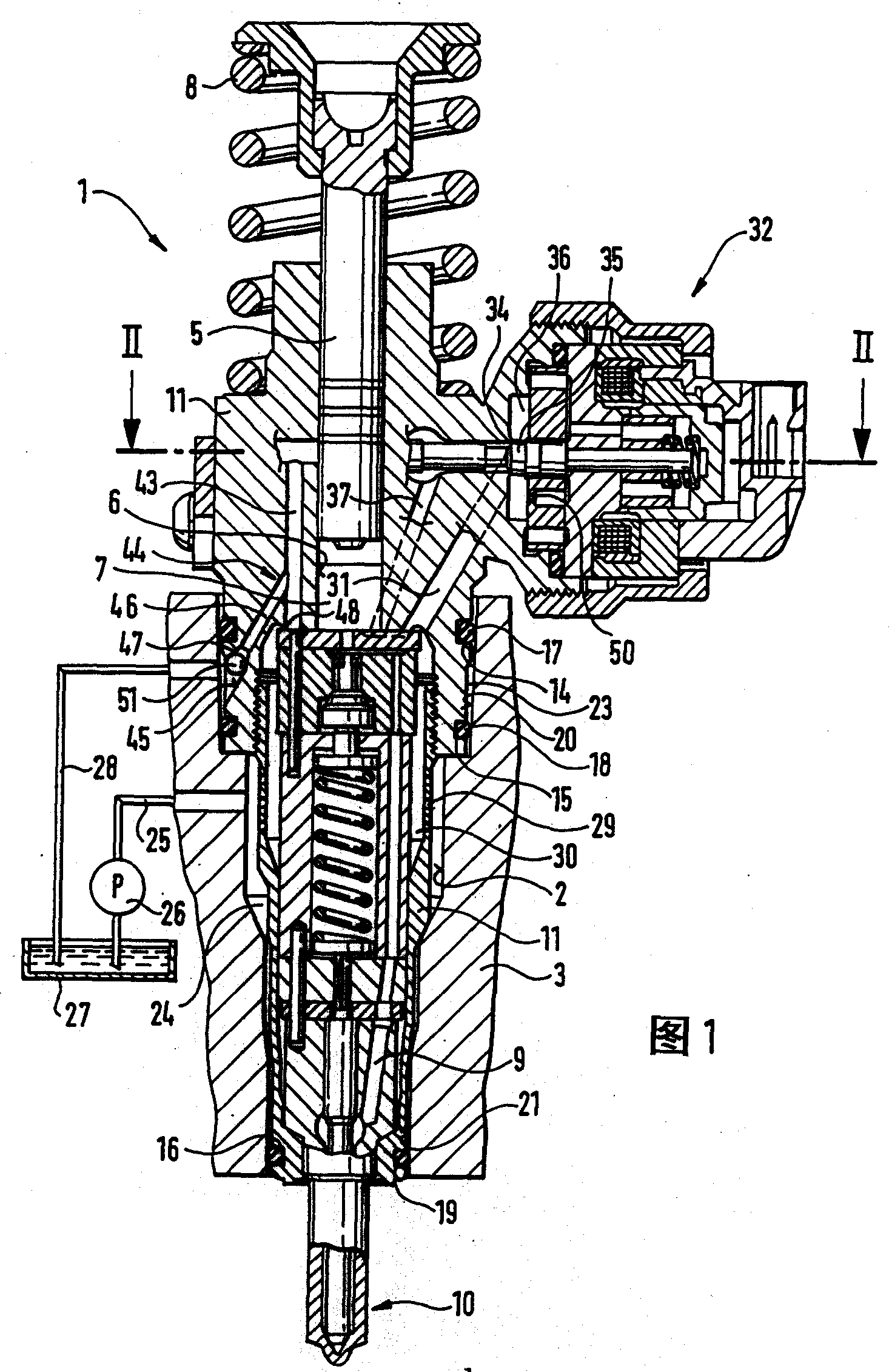

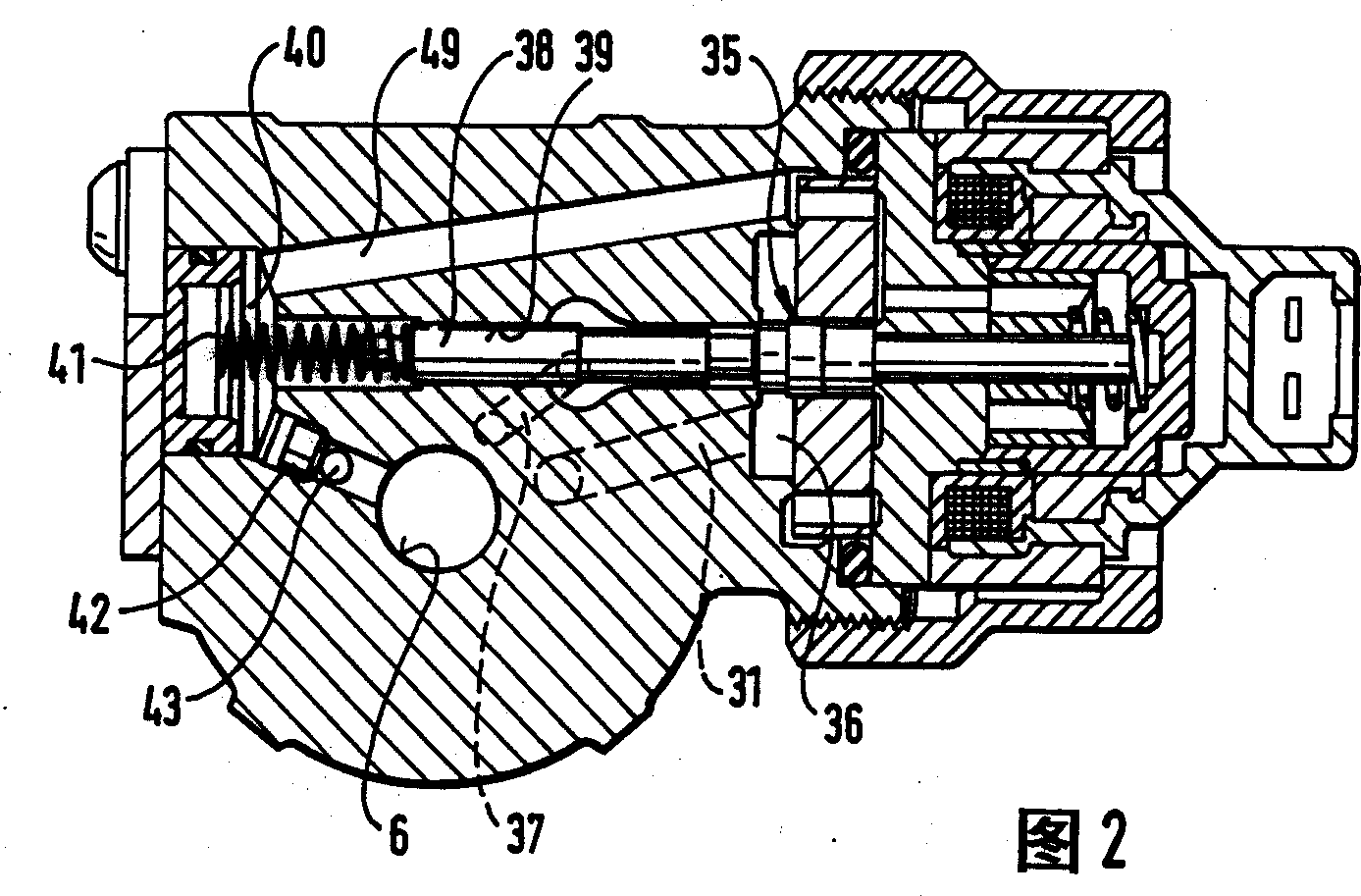

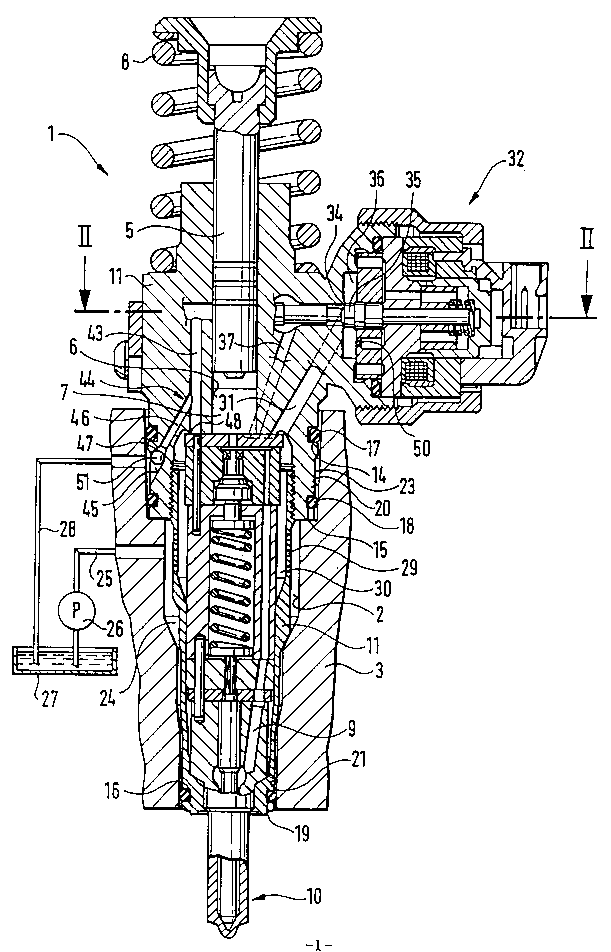

[0012] The fuel injection pump shown in FIG. 1 is a so-called pump nozzle 1 which is inserted into a receptacle 2 in a motor housing 3 . This type of oil pump nozzle has a pump piston 5, which is driven to and fro by a driving device of the engine itself. The pump piston surrounds a pump working chamber 7 in a cylinder bore 6 , from which fuel is supplied via a pressure line 9 to the fuel injection valve 10 when the pump piston moves against the force of a restoring spring 8 . The pump piston, the pump working chamber and the fuel injection valve are located in a common housing 11 consisting of housing parts screwed together. The fuel pump nozzle is characterized by the shortest possible connection between the pump working chamber 7 and the injection point of the fuel injector 10, where the connecting fuel line 9 is guided in a dimensionally stable housing instead of a Normally elastically deformable fuel hose, this hose affects fuel injection due to its displacement.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com