Composite-material core-level cover plate for rocket, and preparation method thereof

A composite material core and composite material technology, which is applied in the foam interlayer, composite assembly structure forming, including internal skeleton, large size, rocket core stage cover and its preparation field, can solve the rigidity and stability of the cantilever cable-stayed structure. Poor, cable-stayed ropes make it inconvenient for operators to walk, and there are potential safety hazards, etc., to improve safety, facilitate disassembly, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

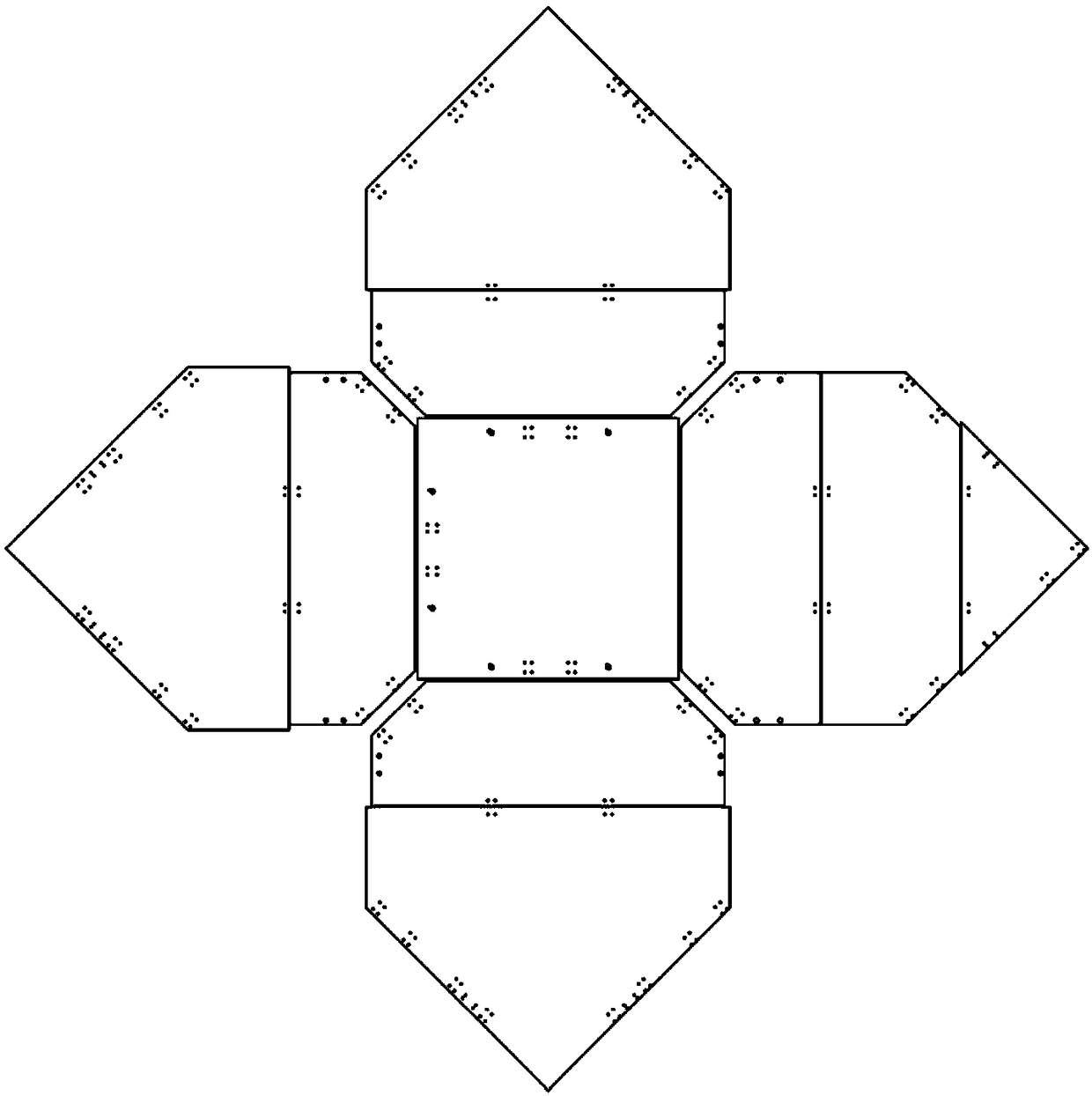

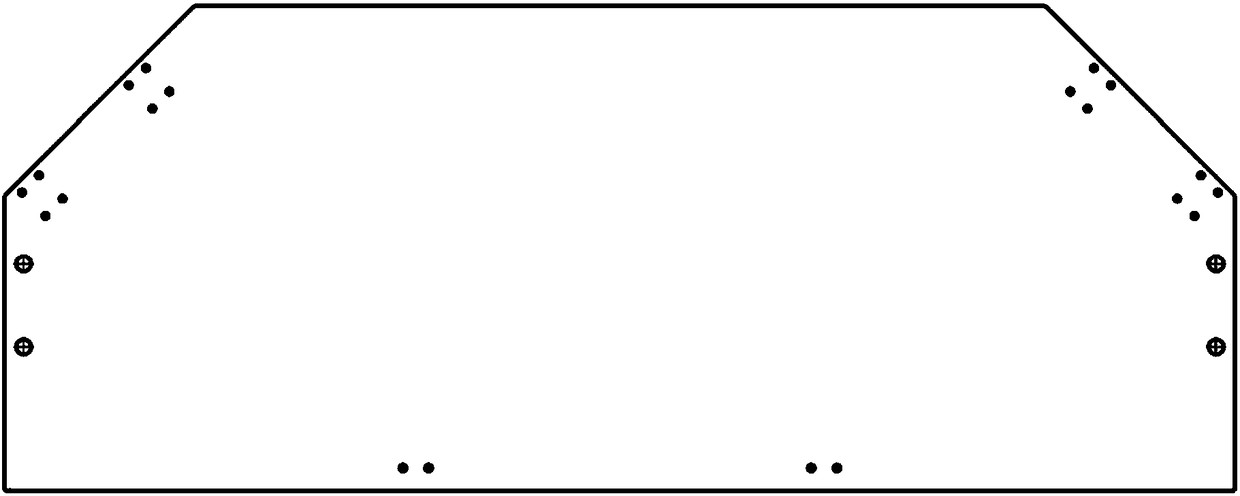

[0047] The preparation method of the cover plate is given below. In this method, each of the above-mentioned detachable units is prepared in the following manner, and after the preparation is completed, the final cover plate is connected according to the above connection method; the internal skeleton is used as a cross grid structure. illustrate. Specific preparation such as Figure 8 As shown, the steps are as follows:

[0048] (1) Process the foam according to the design size and position of the actual foam core material and inner core, such as Figure 7 , Figure 5 As shown; according to the design drawings, for example, the foam at the position of the FRP pre-embedded block is in a disconnected state, and the thickness control at the intersection of the grid skeleton should be considered during the processing. Generally, the thickness of the skeleton skin is 1 to 1.5 times smaller than the design size;

[0049] (2) Build a skeleton forming mold composed of edge stoppe...

example 1

[0060] The metal mandrel, frame mold and pressure equalizing plate are made of Q235 steel. The shape of the product is a quadrilateral flat plate, and the overall size is 1200mm×1200mm×35mm.

[0061] The three sides of the product are simply supported, the center is loaded with a 500kg counterweight, and the load is maintained for 20 minutes. The deformation of the center is 3.7mm, and the deformation of the free side is 2.1mm.

example 2

[0063] The metal mandrel, frame mold and pressure equalizing plate are made of Q235 steel. The shape of the product is a pentagonal flat plate, and the overall size is 1600mm×1300mm×35mm.

[0064] The three sides of the product are simply supported, the center is loaded with a 500kg counterweight, and the load is maintained for 20 minutes. The deformation of the center is 3.7mm, and the deformation of the free side is 2.1mm.

[0065] The four sides of the product are simply supported, and the side in the middle of the two right angles is the free side. A 500kg counterweight is loaded at the center, and the load is maintained for 20 minutes. The deformation of the free side is 13.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com