Three-dimensional printer and three-dimensional printing platform adjustment method

A 3D printer and 3D printing technology, applied in processing platforms/substrates, manufacturing auxiliary devices, processing data acquisition/processing, etc., can solve problems such as abnormal pressure signal lines, failure to connect extruded filaments, and deformation of printing platforms. To achieve the effect of simplifying the design process, preventing deviation and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

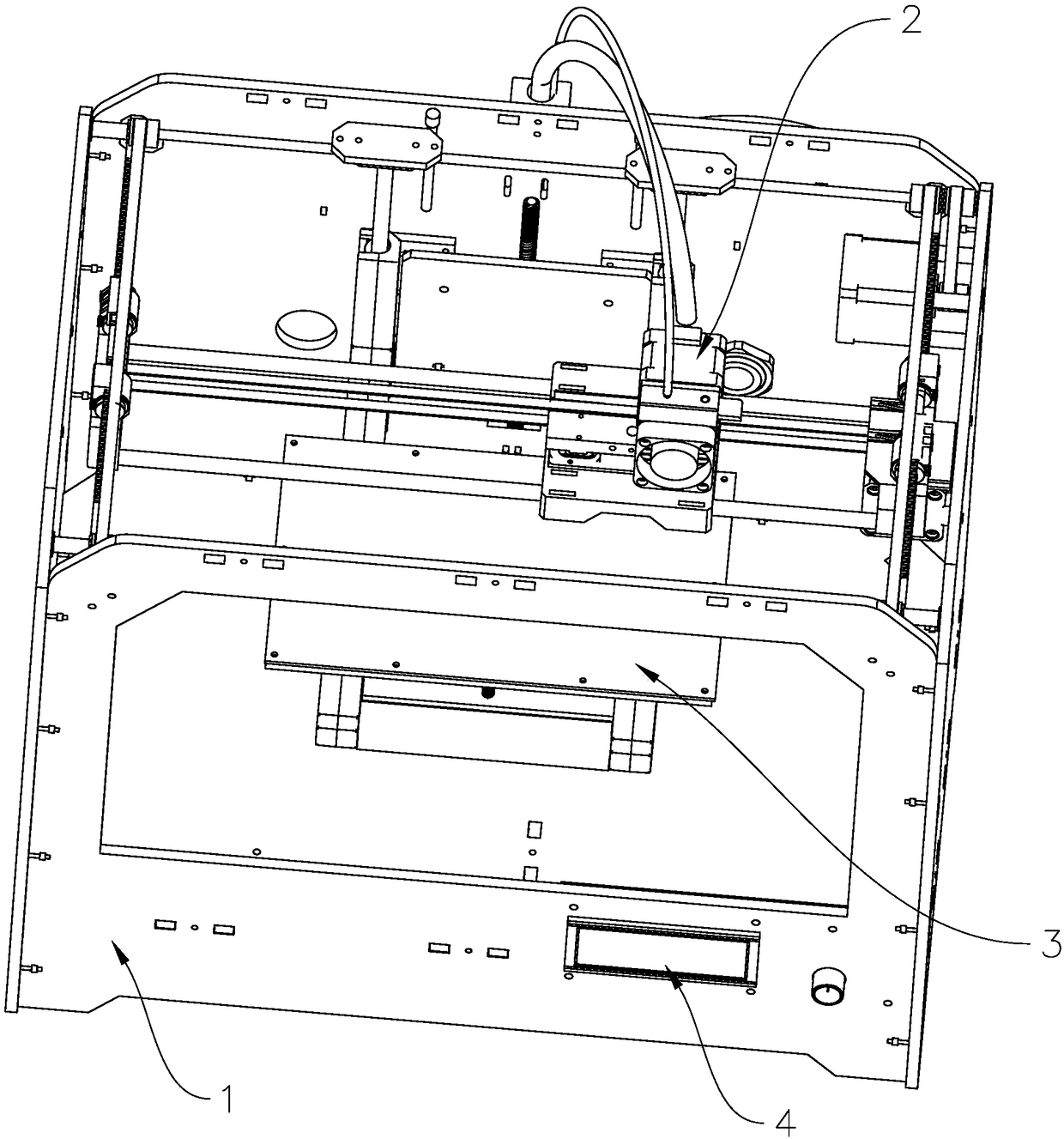

[0036] Such as figure 1 As shown, the 3D printer of the present invention includes a print head device 2 and a 3D printing platform 3 that are installed in a frame 1 of the 3D printer. Wherein, the printing head device 2 can move in the horizontal plane, and the three-dimensional printing platform 3 can move vertically. The 3D printer also includes a control unit (not shown) and a display unit 4 , the control unit is used to control the movement of the printing head device 2 and the 3D printing platform 3 , and the control unit is electrically connected to the display unit 4 .

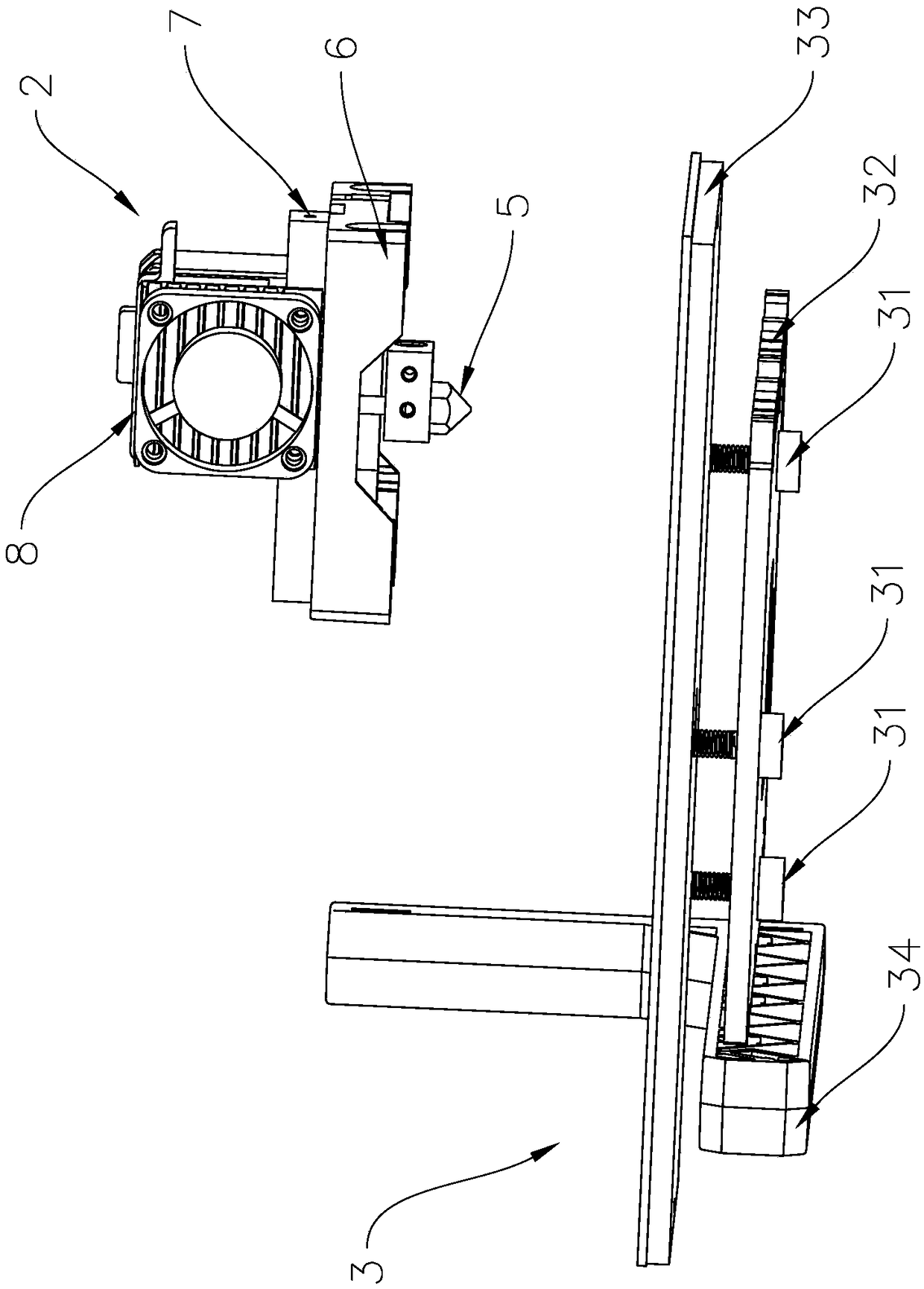

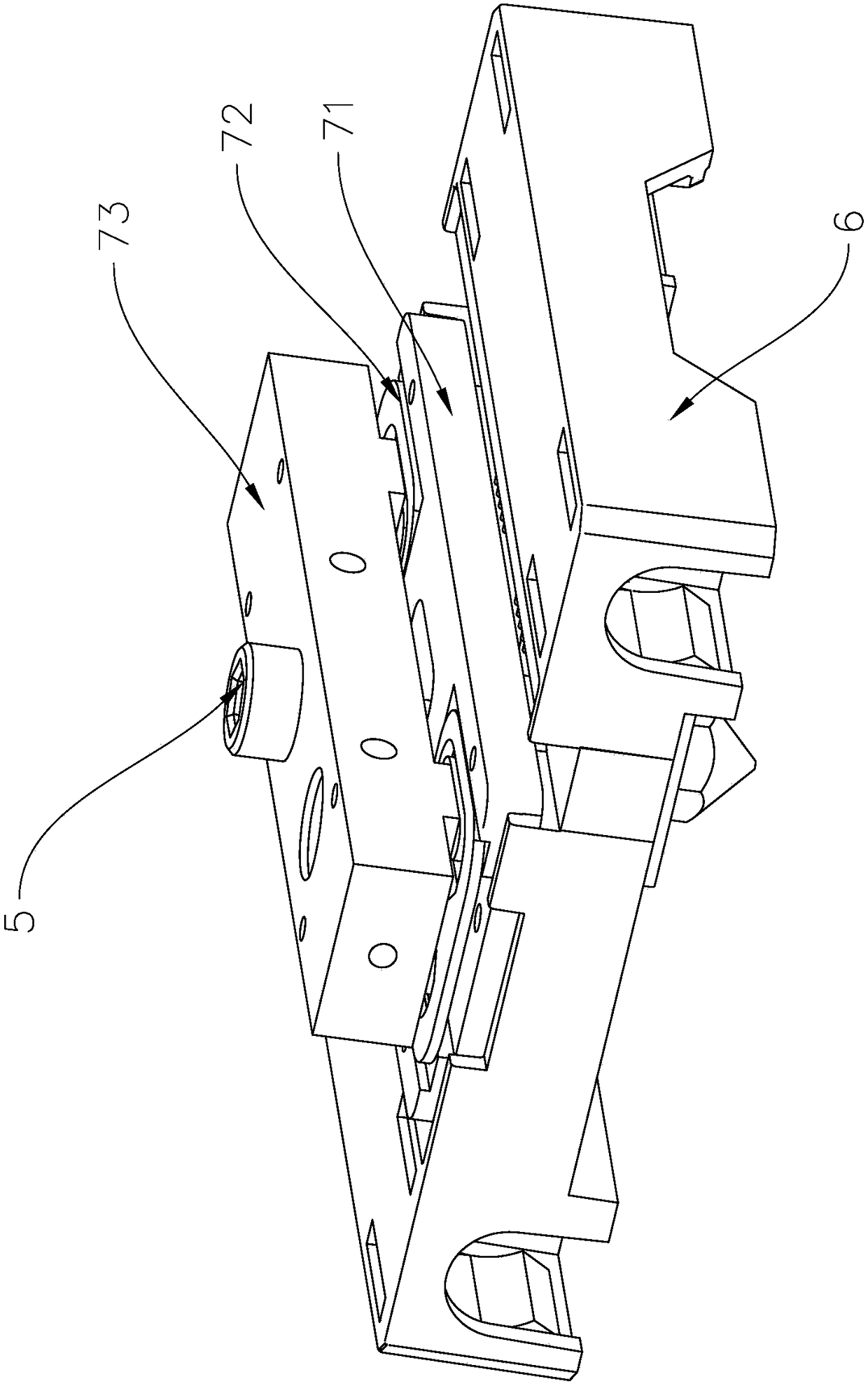

[0037] see figure 2 and image 3, the print head device 2 includes a fixed seat 6, a print head 5 and a pressure sensor module 7, the pressure sensor module 7 is detachably mounted on the fixed seat 6, and the print head 5 is detachably mounted on the pressure sensor module 7. The print head device 2 also includes a driving motor 8 detachably mounted on the fixing base 6, and the driving motor 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com