A rack and pinion transmission material receiving device for a die-cutting machine

A technology of rack and pinion and feeding device, applied in non-rotational vibration suppression, metal processing and other directions, can solve the problems of semi-finished products, inability to easily adjust the tilt position, etc., and achieve the effect of improving quality, reducing temperature and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

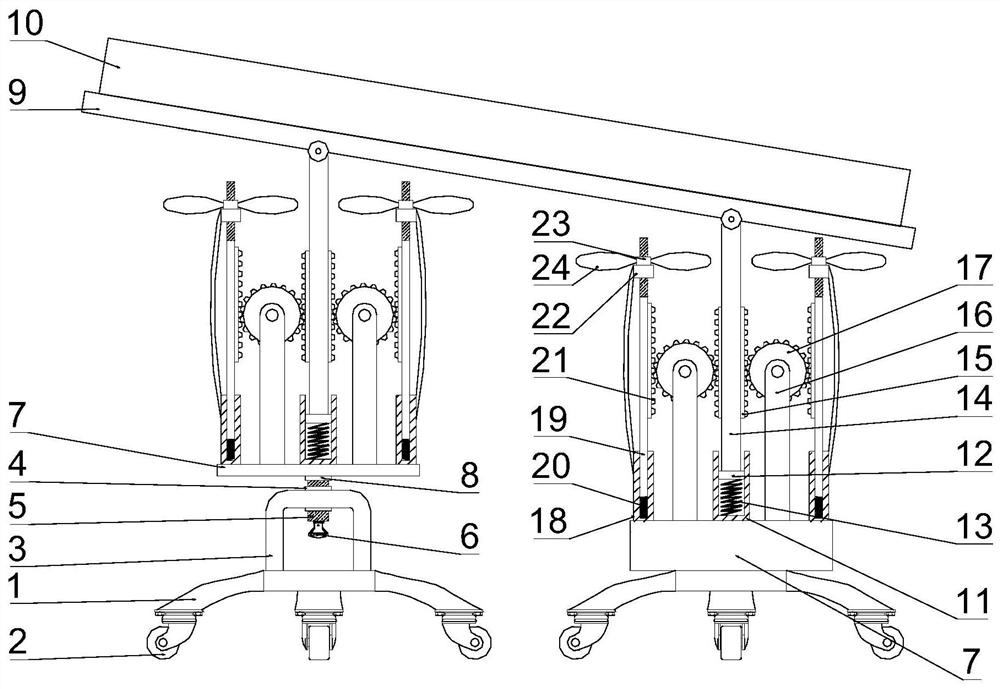

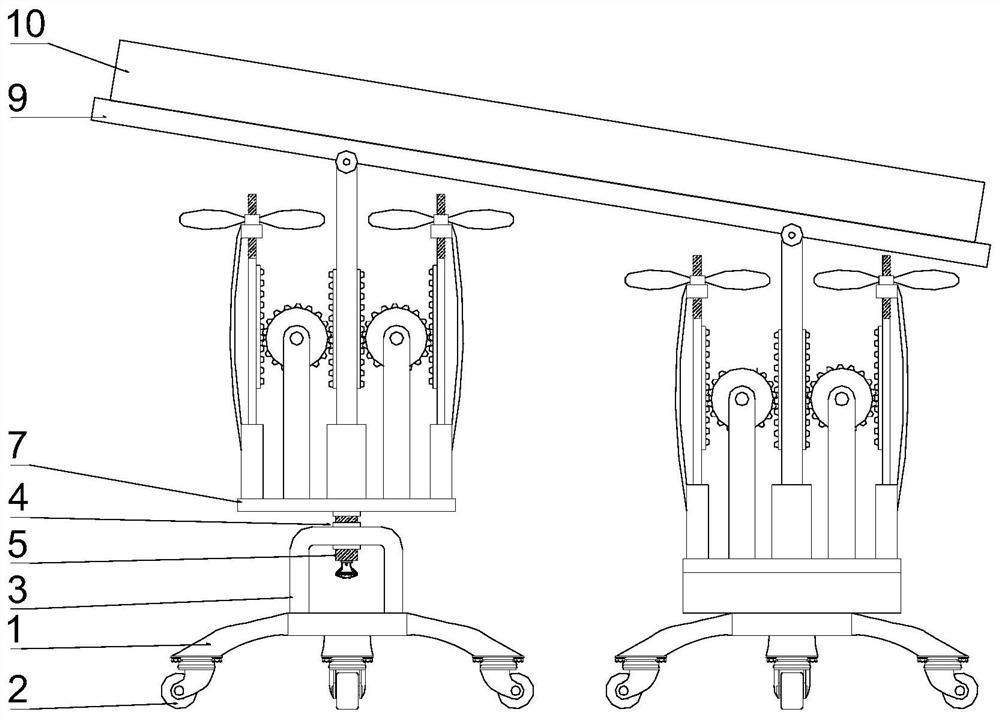

[0022] see Figure 1-2 , a rack and pinion transmission material receiving device for a die-cutting machine, comprising a material receiving plate 9 and a bottom plate 1, the bottom plate 1 is provided with a pair, and the upper part of the bottom plate 1 on the left side is fixedly connected with an inverted U-shaped The mounting frame 3 is fixedly nested with a threaded buckle 4 on the mounting frame 3, and the inside of the threaded button 4 is provided with an internal thread, and the threaded buckle is internally screwed with a threaded column 5, and the upper part of a pair of base plates 1 is provided with a fixed plate 7, which is located at A bearing 8 is installed on the lower surface of the fixed plate 7 on the left side, and the upper polished rod portion of the threaded column 5 is installed in the 8 mounting holes of the bearing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com