Airbag polishing head with self-adjusting air pressure

An airbag polishing and air pressure technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding machine parts, etc., can solve problems such as affecting polishing quality, avoid rigid contact, improve surface quality, and avoid rigidity touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

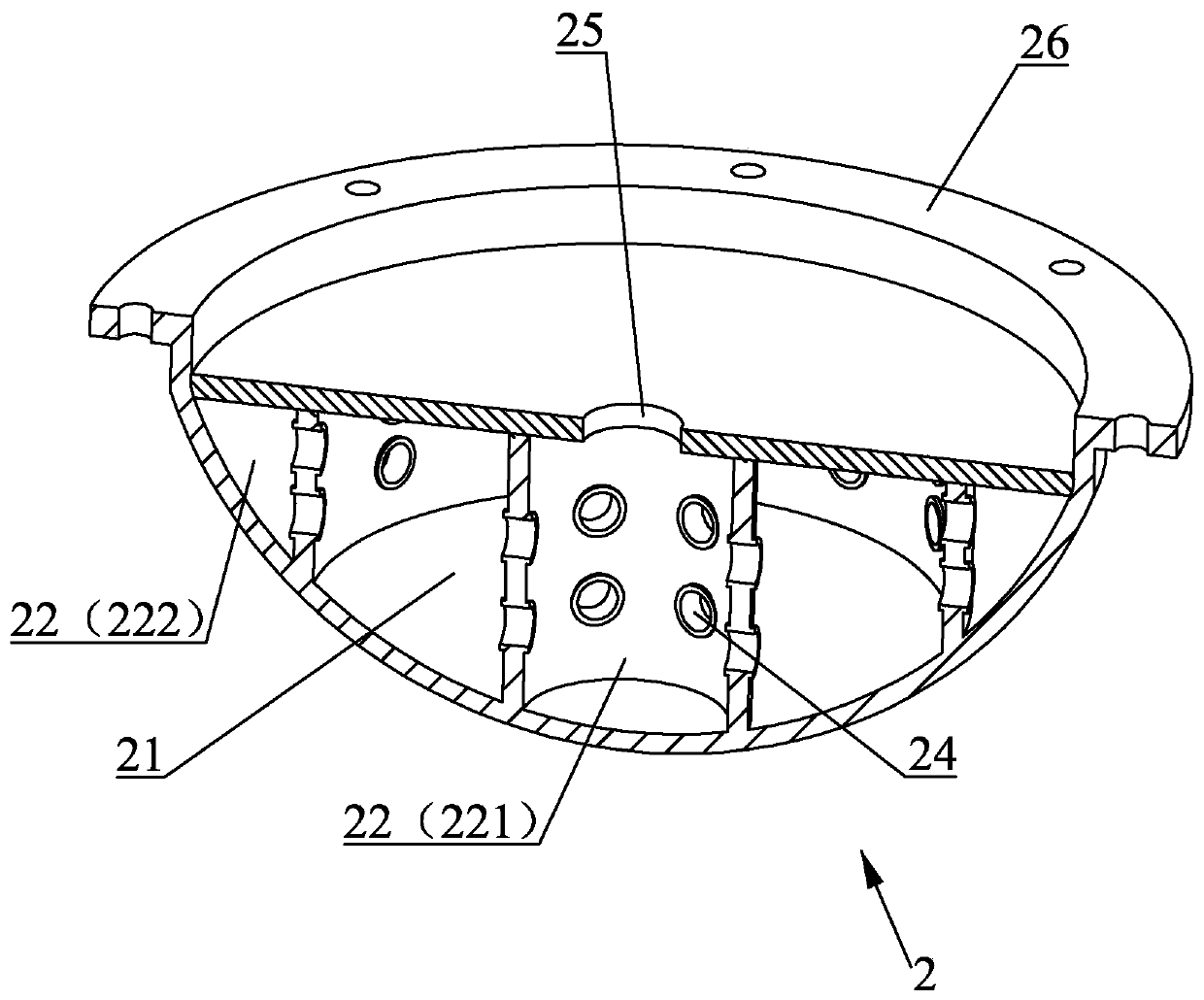

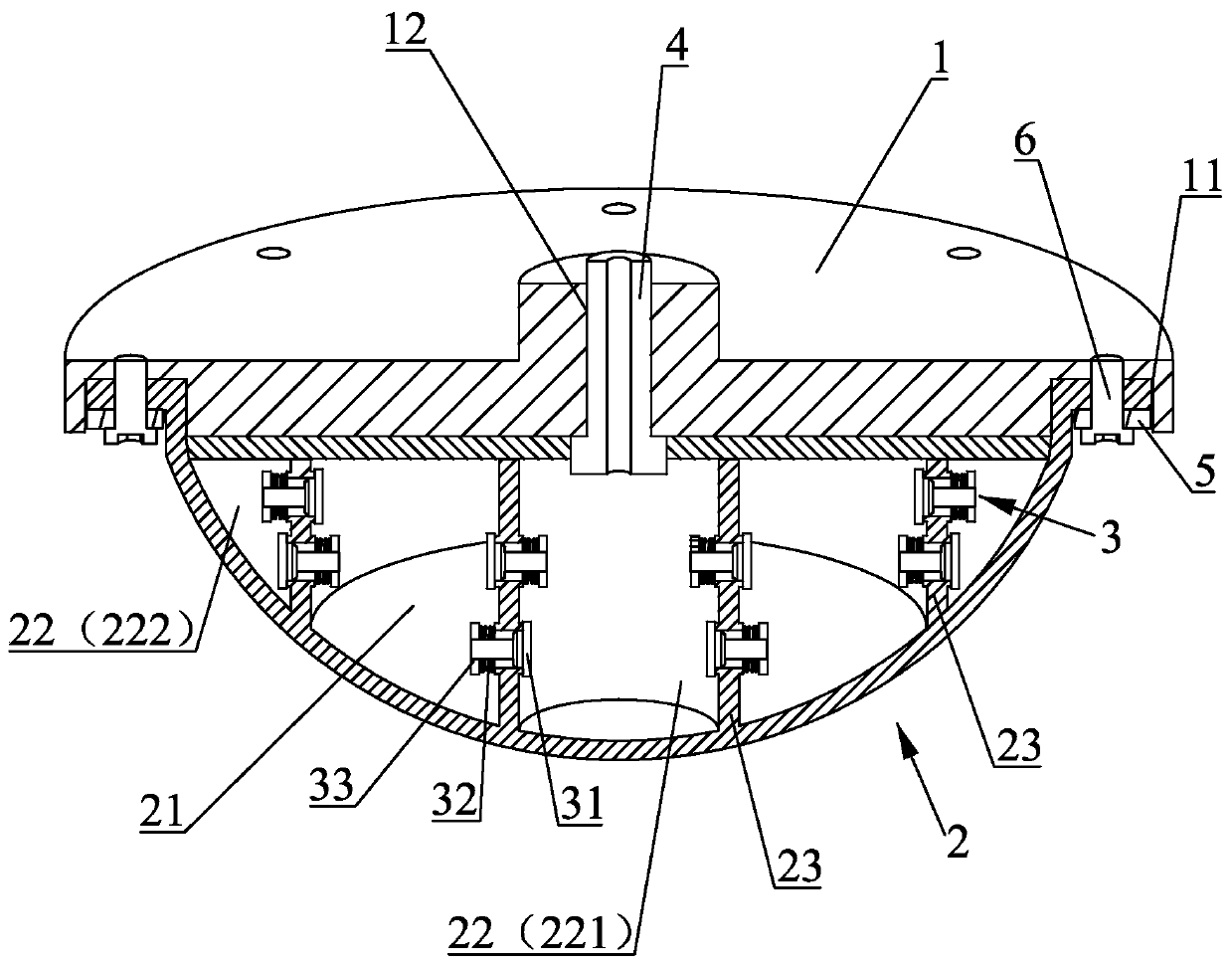

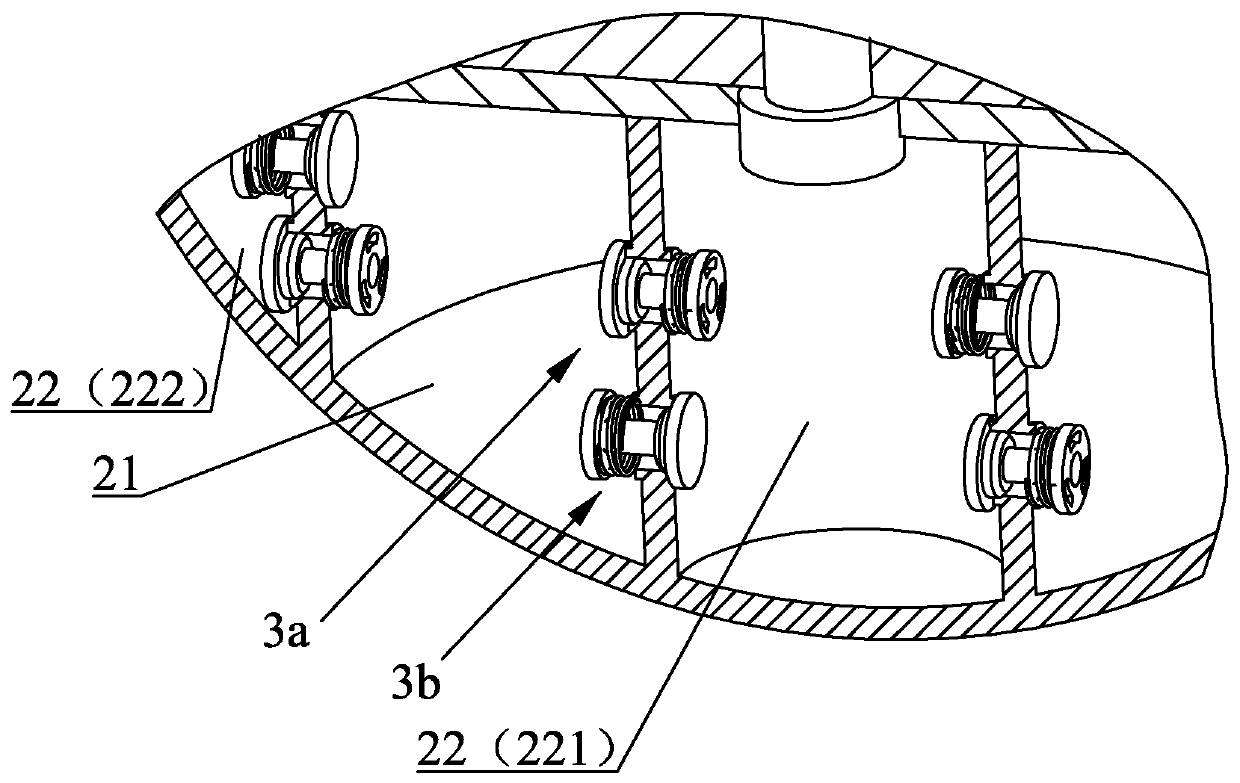

[0028] What the present invention discloses is a kind of air bag polishing head that can self-adjust air pressure, as Figure 1 to Figure 5 Shown is a preferred embodiment of the present invention. The airbag polishing head includes an airbag disc 1 , a polishing airbag 2 , an air pressure self-regulating module 3 and an intake valve 4 . in:

[0029] The airbag disc 1 is used for fixed installation of the polishing airbag 2, and various structures can be adopted for its fixed installation. In this embodiment, an annular groove 11 is provided below the airbag disc 1, and an annular boss 26 is arranged on the outer periphery of the non-processing side of the polished airbag 2. When installing, the annular boss 26 is stuck in the annular groove 11, and then the A compression washer 5 is sleeved on the polishing airbag 2 and located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com