Thin-walled casing part non-chatter processing method and processing fixture thereof

A technology of box parts and processing methods, which is applied in the field of chatter-free processing methods and processing fixtures for thin-wall casing parts, can solve the problems of cutting chatter workpieces, thin-wall processing deformation, and unsolvable problems, so as to improve processing Accuracy, guarantee processing accuracy, improve the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

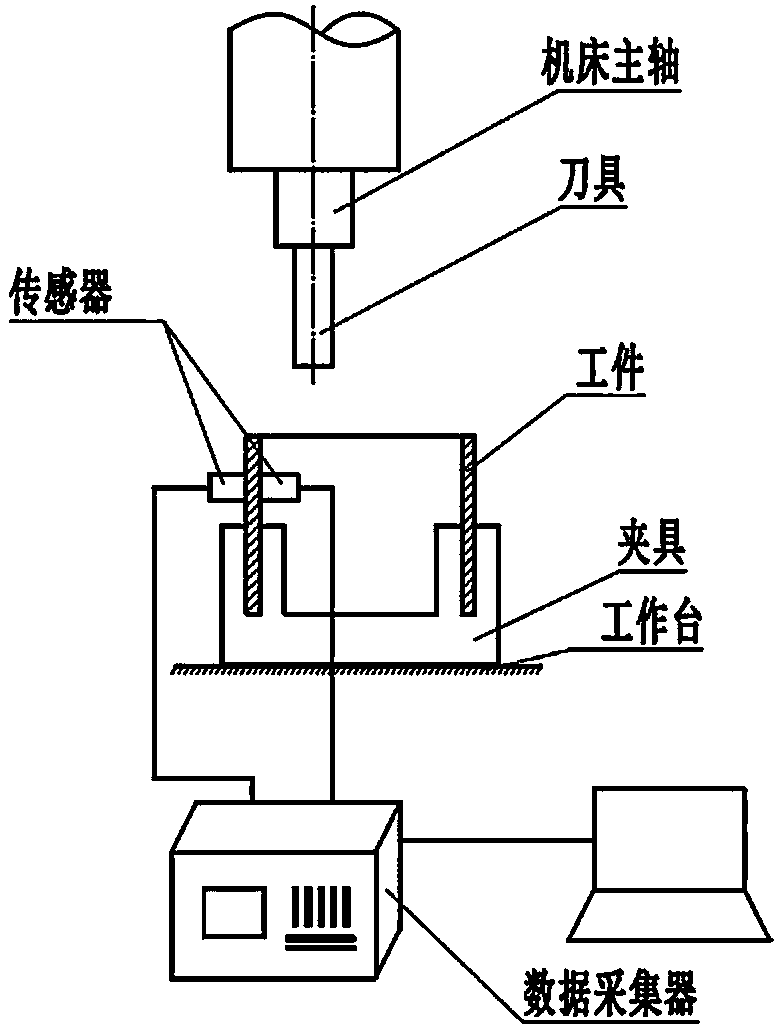

[0025] see figure 1 , the chatter-free processing method of the thin-walled casing parts of the present invention comprises the following steps:

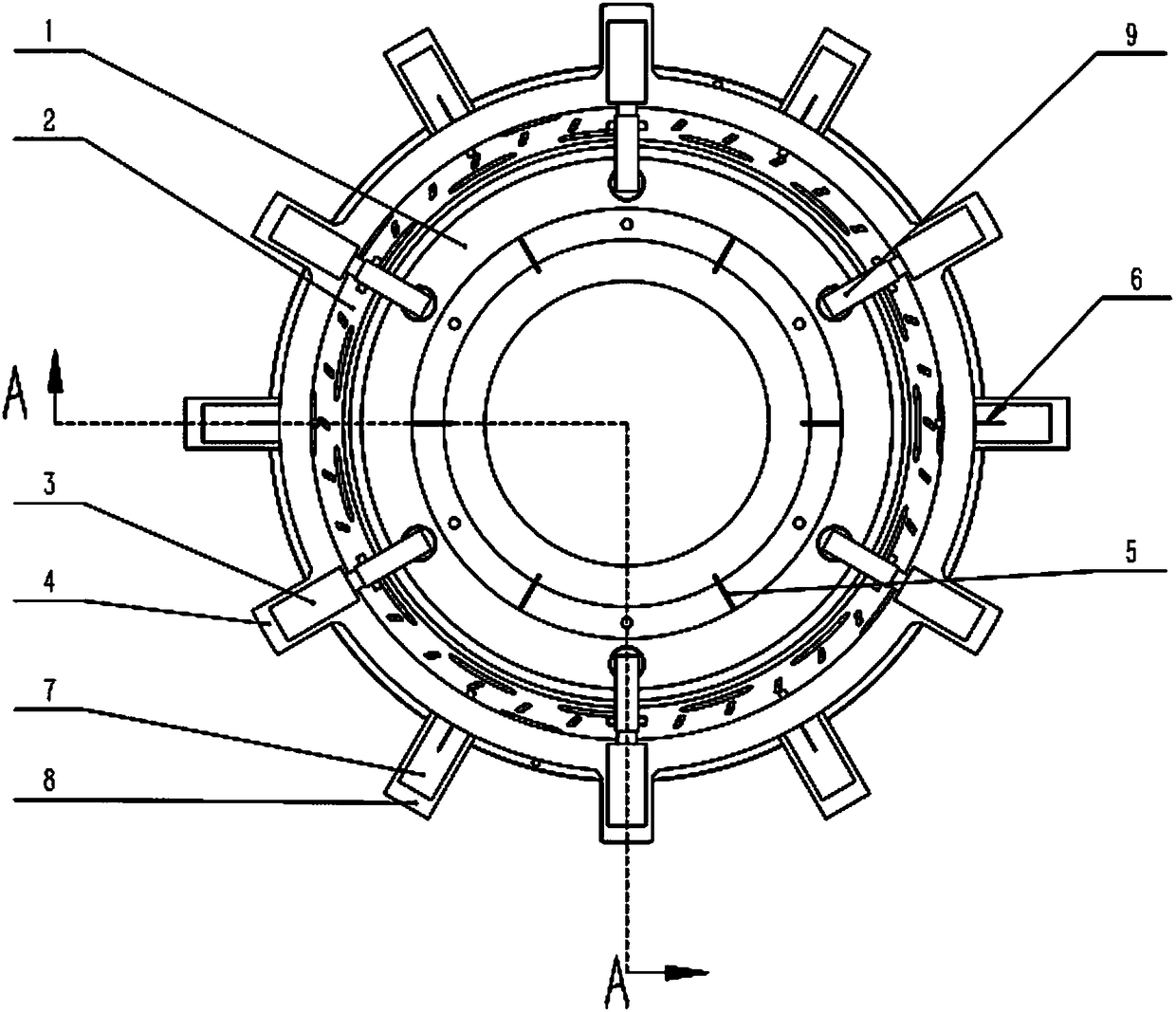

[0026] Step 1. First install the clamping device on the outside of the workpiece, process the inside of the casing 2, monitor the state of the casing 2 during processing in real time through the outside acceleration sensor 6, fix the base 8 on the turntable of the machine tool, and the support block 5 through the pin And connecting bolt 14 is fixed on the base 8. The upper side pressing cylinder 3 clamps the upper side of the casing 2 through the elastic block 11, and the lower side pressing cylinder 7 directly clamps the lower side of the casing 2. Through the joint action of the upper side / lower side pressing cylinders, the machine Clamping positioning of cassette 2.

[0027] After the milling process starts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com