Powder supplying center capable of being automatically cleaned

A powder supply center and automatic cleaning technology, applied in the direction of liquid supply devices, etc., can solve the problems of long time consumption, external environmental pollution, low degree of automation, etc., and achieve the effects of easy maintenance and cleaning, good fluidization effect, and simplified settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

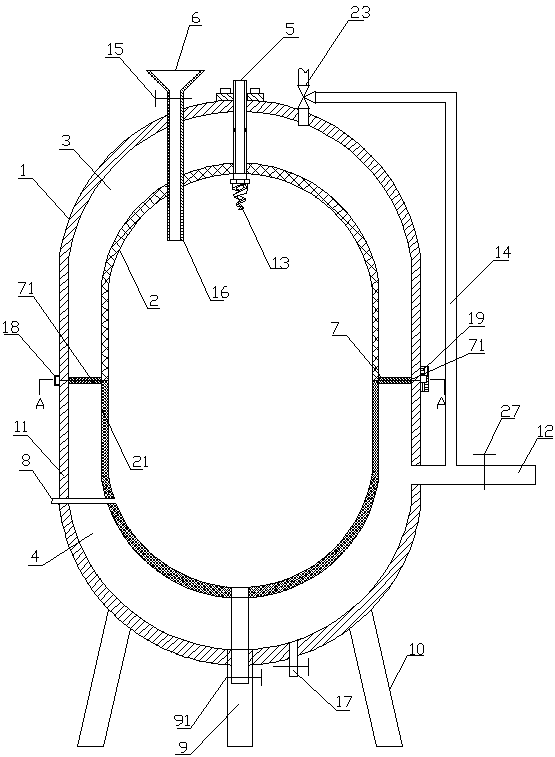

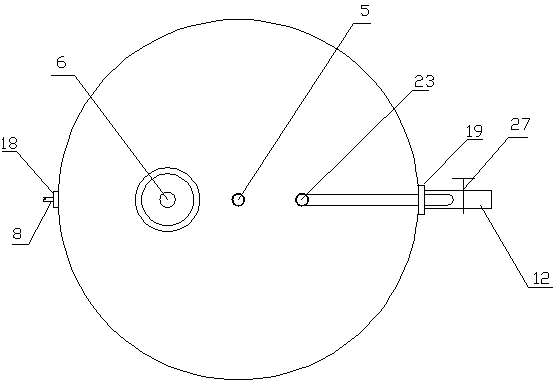

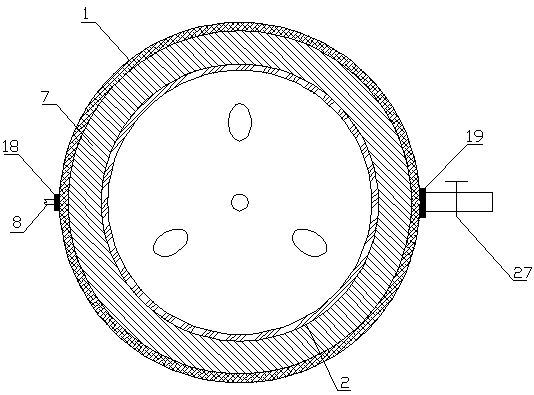

[0023] Such as Figure 1-Figure 3 The shown self-cleaning powder supply center includes a bracket 10 on which a pressure-holding shell is installed, and the pressure-holding shell is composed of an upper pressure-holding shell 1 and a lower pressure-holding shell hinged with the upper pressure-holding shell 1. The upper pressure-holding shell 1 and the lower pressure-holding shell 11 are both oval-shaped and arranged up and down. The pages are hinged together, and when turned over and closed, the lower surface of the upper pressure-holding shell 1 and the upper surface of the lower pressure-holding shell 11 are bonded and sealed, and the upper pressure-holding shell 1 and the other side of the lower pressure-holding shell 11 pass through The hoop 18 is connected, and the connection structure of the hoop 18 is the prior art. Such as figure 1 As shown, a powder bucket is suspended in the pressure-holding housing, and the powder bucket is composed of an upper powder bucket 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com