Forming equipment of paper-parcel-free coaxial core filter stick and running process of forming equipment

A molding equipment and coaxial core technology, applied in the fields of e-liquid filter elements, applications, tobacco, etc., can solve the problems of unintroduced paperless coaxial filter rod forming technology, undisclosed coaxial filter rod forming technology, etc., to achieve The shape of the end face is simple and beautiful, saving the use cost and reducing the input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

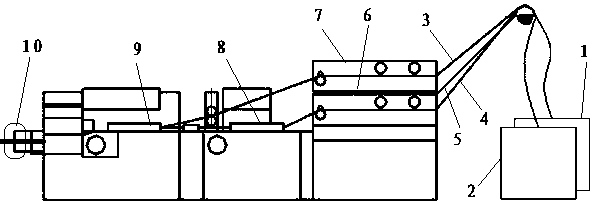

[0022] Such as figure 1 The forming equipment for a coaxial core filter rod without a paper wrapping shown in the figure has an outer layer tow transmission mechanism and an inner layer tow transmission mechanism, a combined opening mechanism, an inner layer without a paper wrapping filter core curing and shaping mechanism, The outer layer has no paper bag filter element for solidification and shaping, composite molding mechanism, and filter rod lead-out mechanism.

[0023] The outer layer tow transmission mechanism and the inner layer tow transmission mechanism are jointly connected to the combined opening mechanism;

[0024] The combination opening mechanism has upper and lower rows of opening branches, which respectively open the inner layer tow and the outer layer tow, and the two groups of tows are opened and the walking speed is synchronized; the outer layer of tow passes through and opens in the upper row , the inner layer tow is passed and opened in the lower row.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com