Optical transparent adhesive sheet, optical transparent adhesive sheet production method, laminate, and touch panel-equipped display device

A technology of optically transparent and adhesive sheets, which is applied in chemical instruments and methods, adhesive products, identification devices, etc., can solve the problems of consumption and difficulty in obtaining thick-film OCA sheets, etc., to improve operability, improve visibility, The effect of suppressing whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] First, a solid hydrogenated petroleum resin-based thickener (IMARV P-100) is added to polyolefin polyol (EPOL) at a temperature of 100°C to 150°C, and stirred to obtain a thickener-dissolved Thickener masterbatch in polyolefin polyol. The content of the thickener in the thickener masterbatch was adjusted to 30% by weight. Then, using a reciprocating rotary mixer AJITER (AJITER) to mix 100 parts by weight of polyolefin polyol (EPOL), 24 parts by weight of HDI-based polyisocyanate A, 163 parts by weight of thickener masterbatch and 0.01 parts by weight of catalyst (Dimethyltin dilaurate) was stirred and mixed to prepare a thermosetting polyurethane composition.

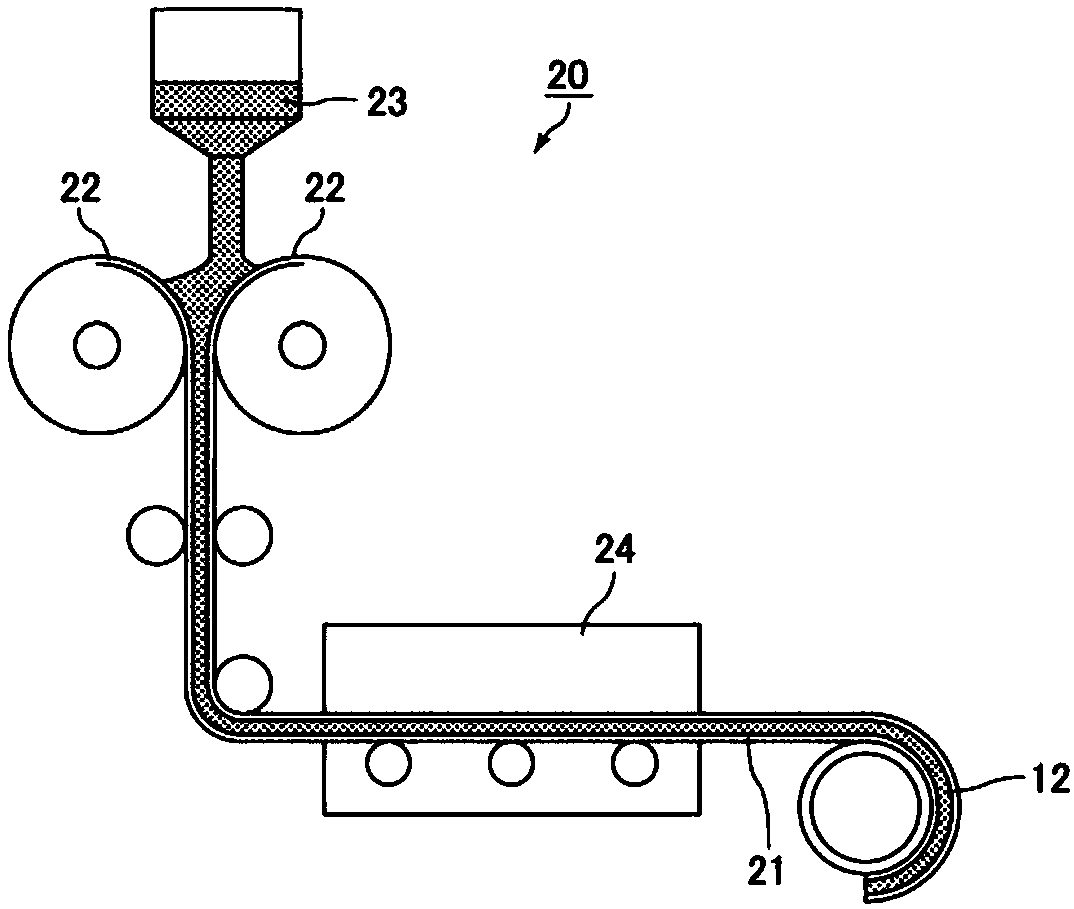

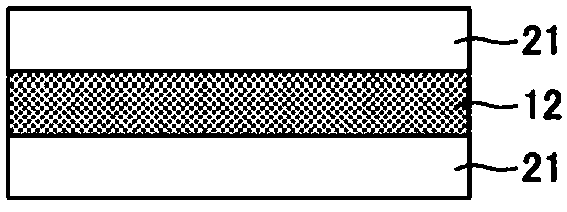

[0113] Thereafter, the obtained thermosetting polyurethane composition was injected into figure 2 The forming device 20 is shown. Furthermore, the thermosetting polyurethane composition was transported while being sandwiched by a pair of release films (PET film with a release treatment on the surface) 21, and...

Embodiment 2~ Embodiment 5 and comparative example 1~ comparative example 4

[0116] Except for changing the formulation or the thickness of the optically transparent adhesive sheet as shown in the following Table 1, it was carried out in the same manner as in Example 1, and the mold release films of Examples 2 to 5 and Comparative Examples 1 to 4 were produced, respectively. optically clear adhesive sheet.

[0117]

[0118] Furthermore, in the above-mentioned Table 1, "HDI-based A" means "HDI-based polyisocyanate A", "HDI-based B" means "HDI-based polyisocyanate B", and "HDI-based C" means "HDI-based polyisocyanate C". , "HDI-based D" means "HDI-based polyisocyanate D", and "HDI-based E" means "HDI-based polyisocyanate E".

[0119] (Characteristics and Evaluation of Optically Clear Adhesive Sheets)

[0120] Regarding the optically clear adhesive sheets with release films produced in Examples and Comparative Examples, (1) measurement of moisture absorption, (2) measurement of initial haze, (3) after high-temperature and high-humidity test were carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com