Railway gauge block mold with fine-tuning size and its size fine-tuning method

A railway track and size technology, which is applied in the field of railway gauge block production, can solve problems such as time-consuming and labor-intensive, increased risk of customer complaints, and increased mold costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

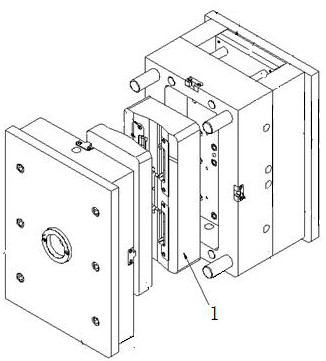

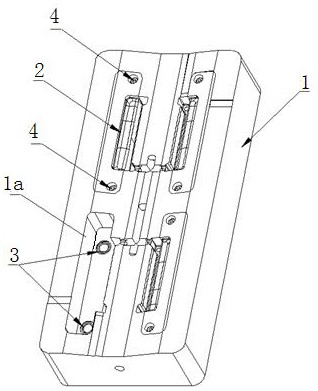

[0036] The following will be attached Figure 1~4 The present invention is further described with examples.

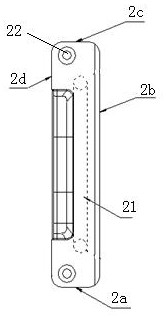

[0037] The railway gauge block mold whose size can be finely adjusted is characterized in that it includes a movable mold core 1 and a detachable insert 2 installed in the mold cavity 1a of the movable mold core, and the number of said inserts 2 is multiple , and because the corresponding product sizes are different, the specifications and models of each insert are different, and each insert 2 can be installed in cooperation with the mold cavity 1a.

[0038] As shown in the figure, there are four mold cavities 1a on the movable mold core 1, and an insert 2 is installed in each mold cavity. By installing inserts with different specifications and models in the mold cavity 1a, the mold production can be changed. The size of the produced product, including the gauge side thickness, angle and crimping side thickness, so as to realize the fine adjustment of the product size...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com