Adjustable type equipment clamping device

A clamping device and adjustable technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of complex structure, low clamping force of manipulators, and high manufacturing costs, and achieve flexible rotation process, large clamping force, and structure. Streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

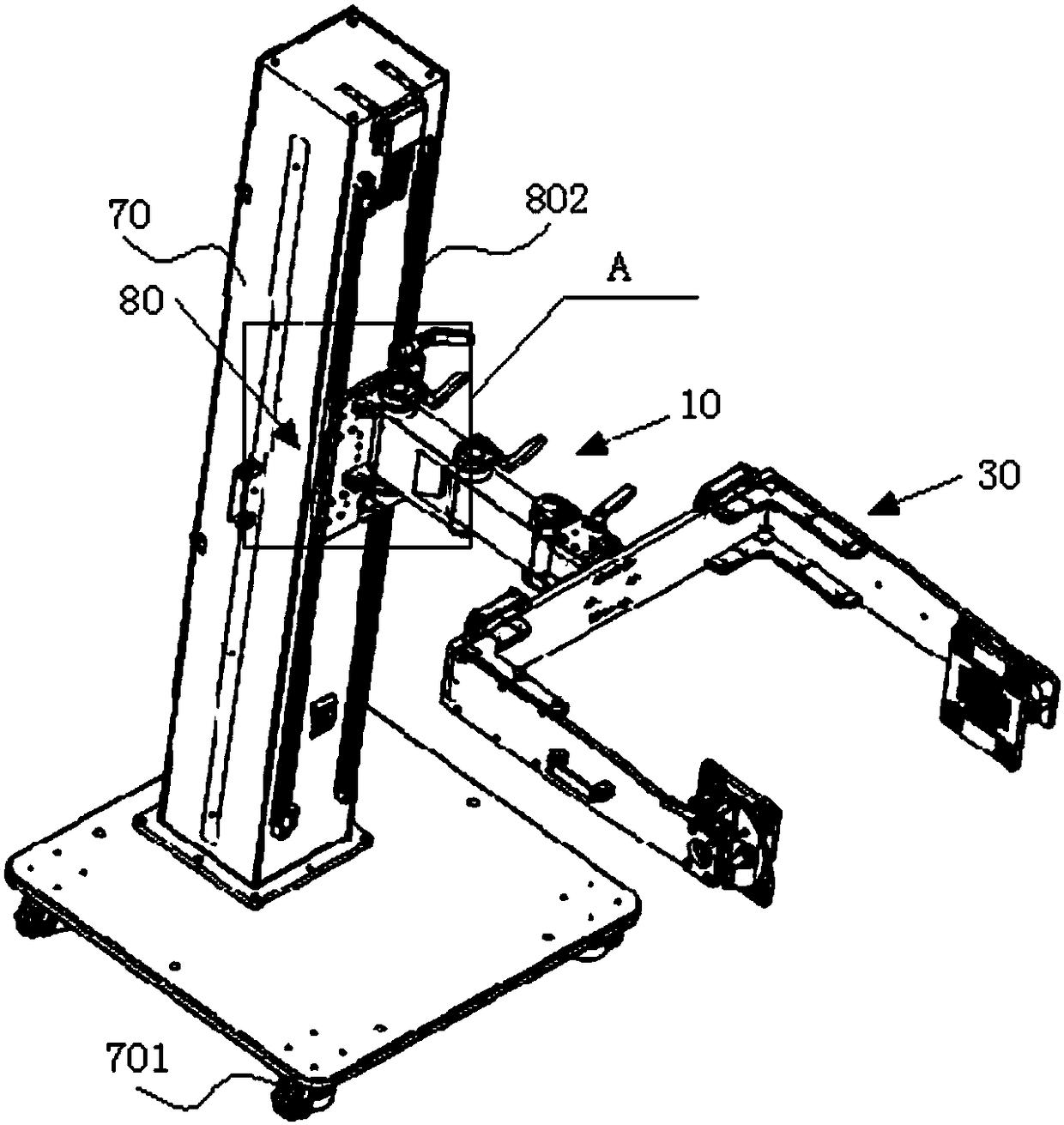

[0054] Embodiment: an adjustable equipment clamping device, such as figure 1 As shown, it includes a frame 70, a manipulator installed on the frame, and a longitudinal sliding structure 80 that drives the manipulator up and down;

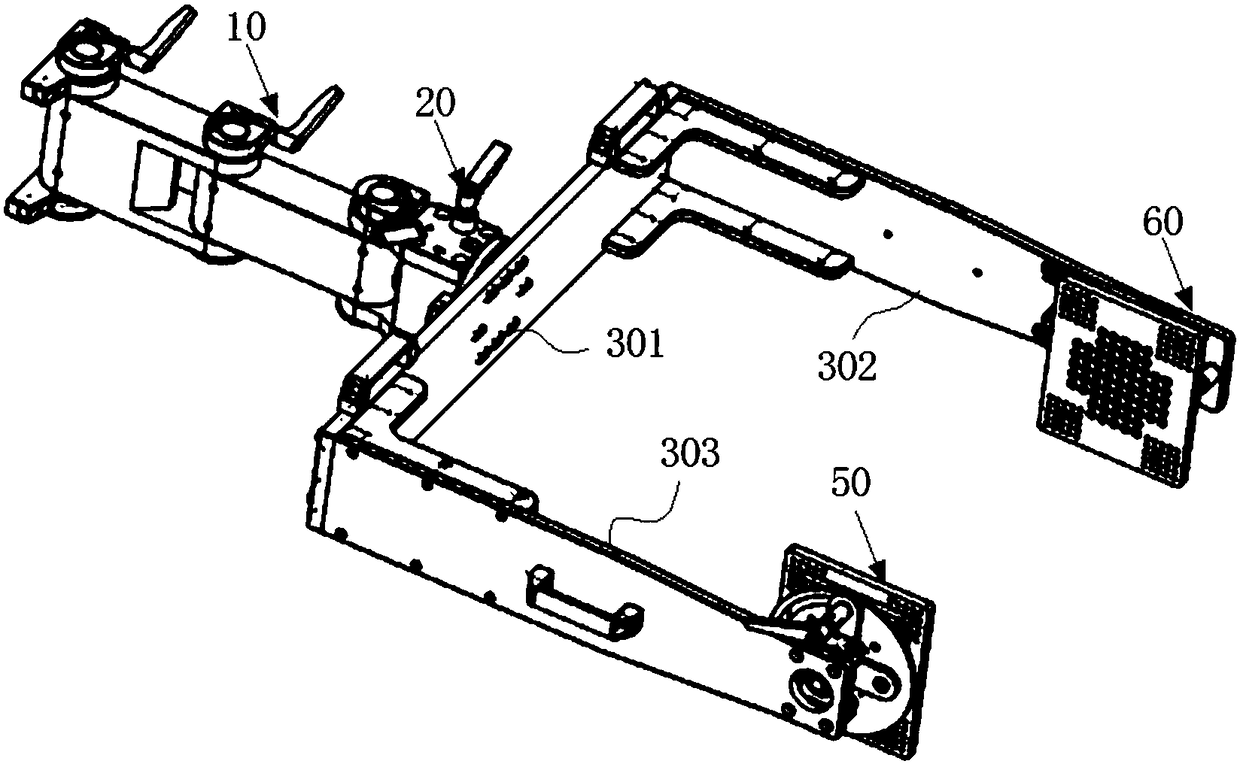

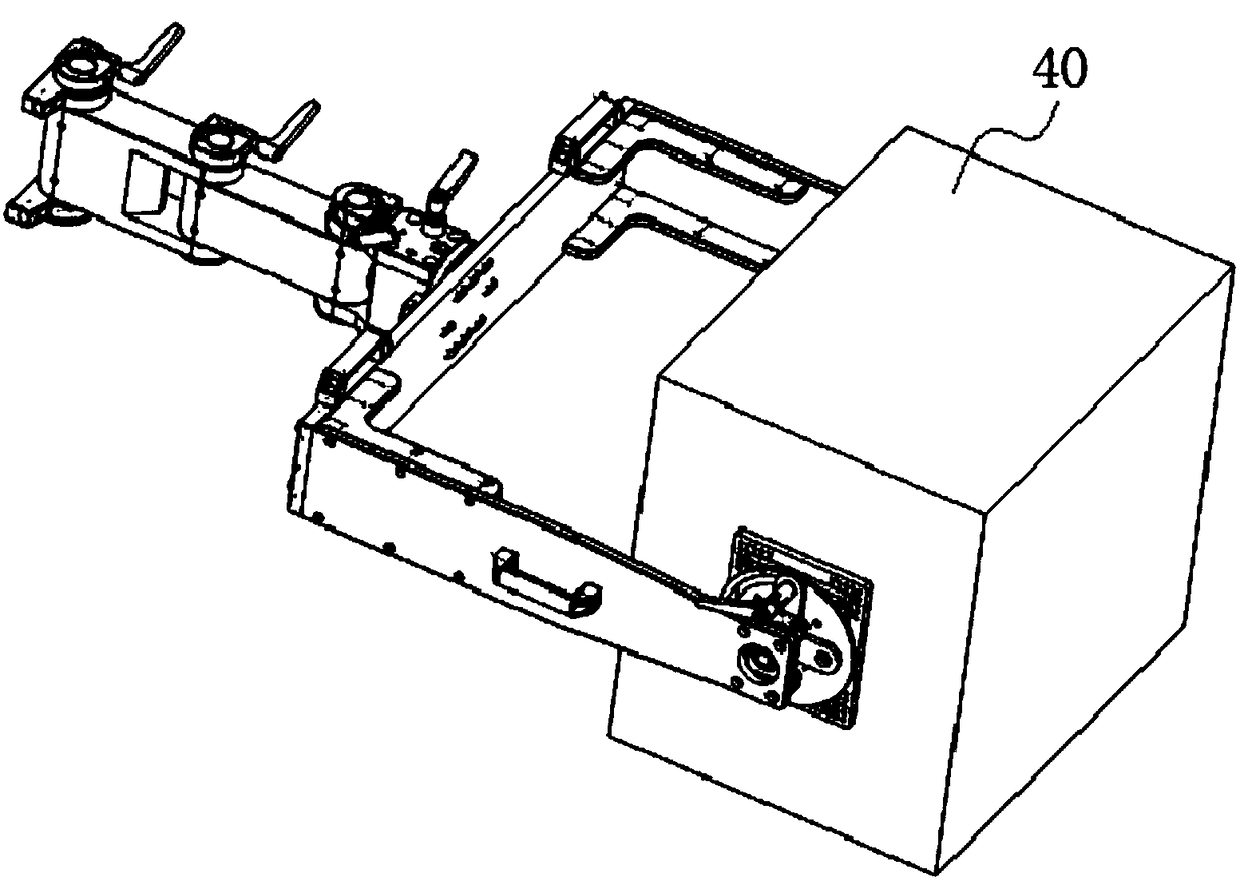

[0055] Such as Figure 1 to Figure 10 As shown, the manipulator includes a reversing structure 10, a locking structure 20 and a clamping arm 30, one end of the locking structure is connected to the reversing structure, and the other end is connected to the clamping arm; The arm of the clamping arm includes a left arm 302 and a right arm 303 capable of clamping the device 40 to be clamped, the left arm and the right arm are parallel to each other, and the opening of the clamping arm is defined as the front, and Taking the side close to the device as the inside, one of the front end of the left arm and the front end of the right arm is provided with a first clamping mechanism 50, and the other has a second clamping mechanism 60, through which the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com