Alloy-box travel suitcase

A suitcase and box body technology, applied in the field of suitcases, can solve the problems of high cost, difficulty in popularization, and heavy weight, etc., and achieve the effect of light weight, low price, and enhanced impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

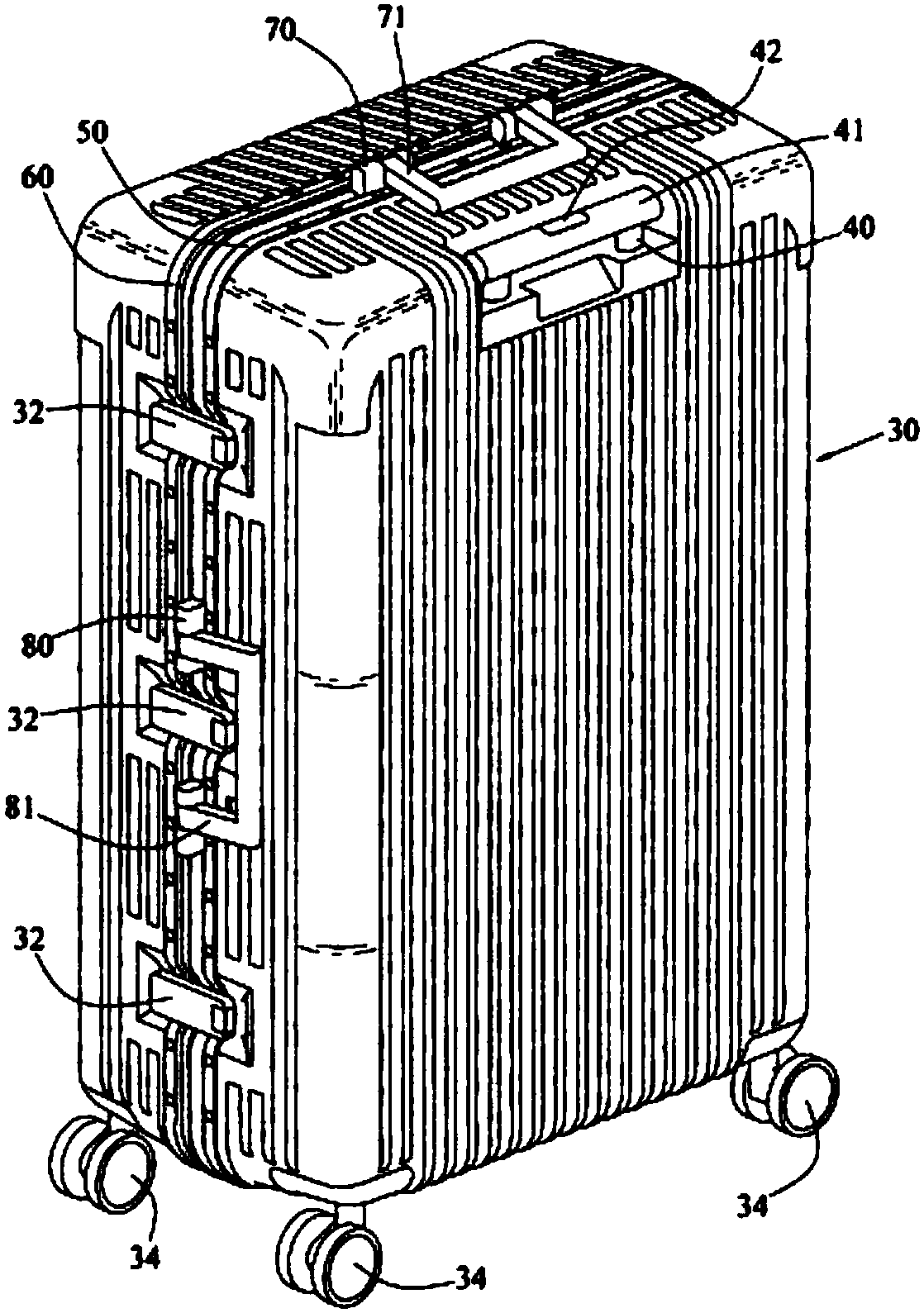

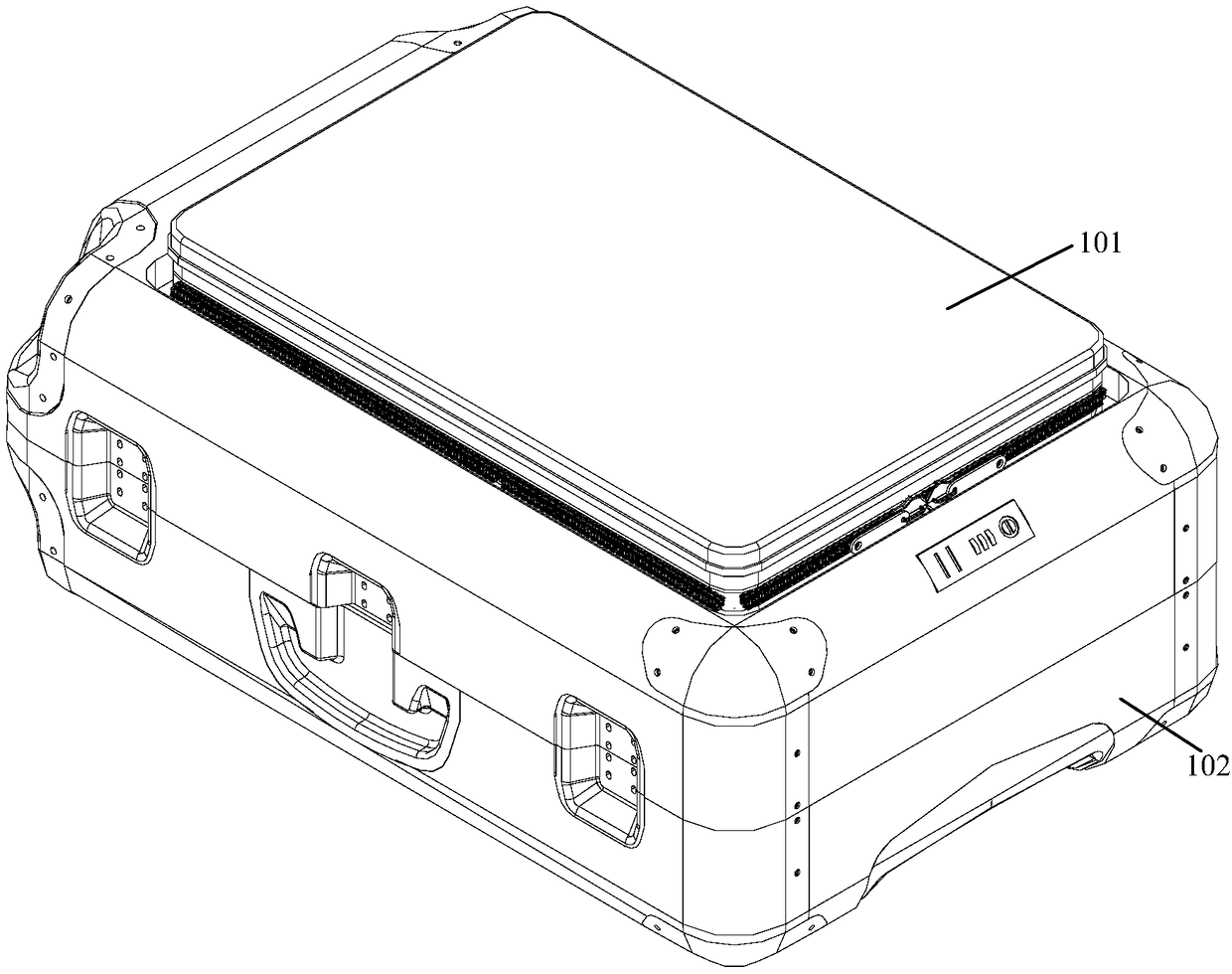

[0022] As shown in the figure, this embodiment provides an alloy box suitcase, which includes a hollow housing part 100 composed of a first box body 101 and a second box body 102 made of alloy material, which are interlocked with each other. The first box body 101 Hinged with the second box body 102; on the first box body 101 and the second box body 102 and at the edge positions where the two are fastened to each other, a transition connection belt 103 is respectively provided, and one of the transition connection belts 103 One side is sewed or bonded to the cloth tape 105a of the zipper 105 by a suture 104, and the other side is riveted by a rivet 106 or bonded to the edge of the first box 101 or the second box 102 by an adhesive. Location.

[0023] The transition connecting strip 103 is a material that can be riveted or bonded to the edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com