Ultra-high-efficiency energy-saving rare earth permanent-magnet synchronous motor

A rare-earth permanent magnet and synchronous motor technology, which is applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, and parts of synchronous machines, can solve problems such as high cost, unreliable connection, and inaccurate adjustment. Achieve the effect of low production cost, good self-locking effect and high adjustment precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

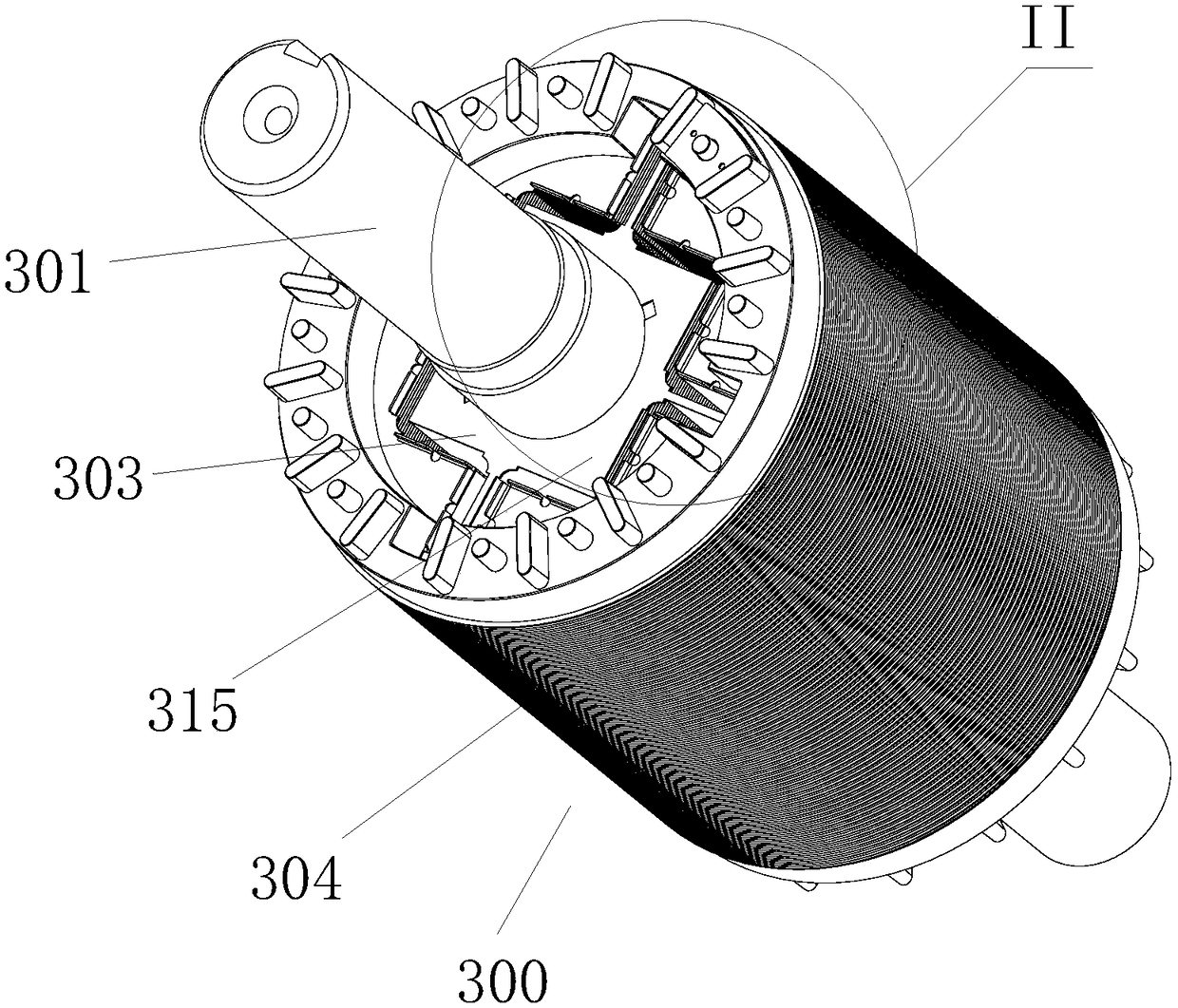

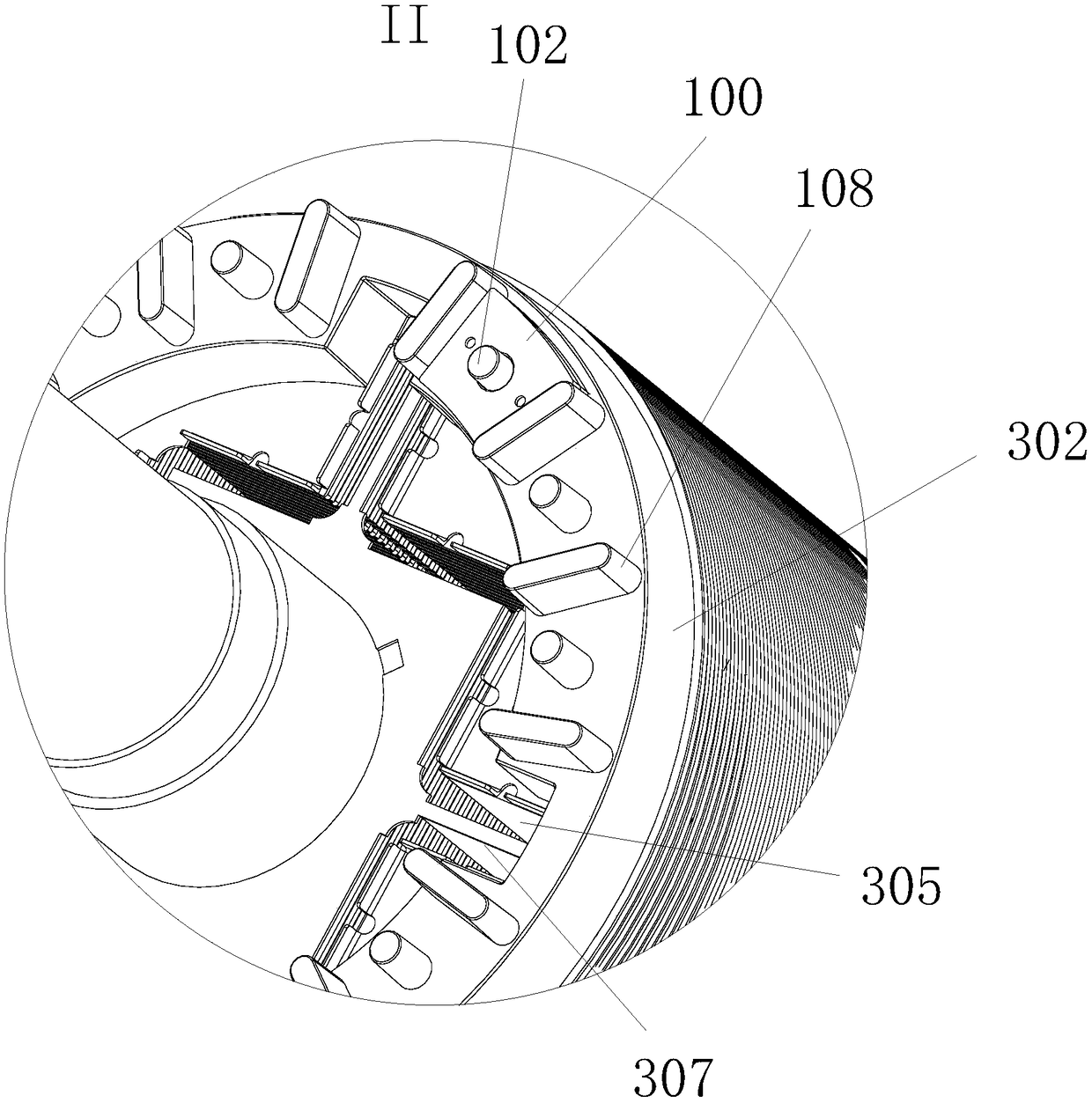

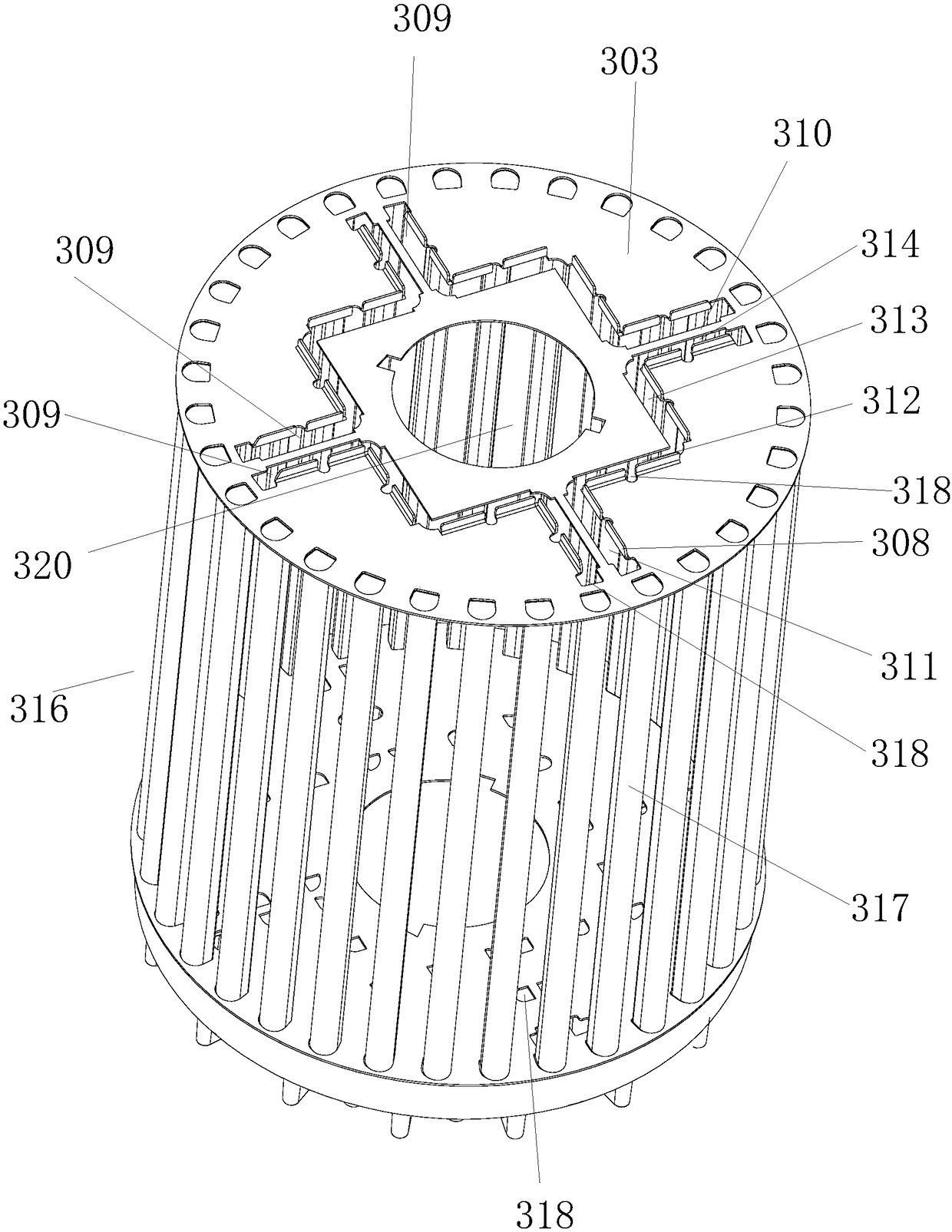

[0036] Such as Figure 1 to Figure 12 As shown, the ultra-ultra-high-efficiency energy-saving rare earth permanent magnet synchronous motor includes a casing 150. A rotor body 300 is arranged inside the casing 150. The rotor body 300 includes a rotating shaft 301. Short-circuit rings 302 are arranged at both ends of the rotor body 300. The short-circuit rings 302 A stopper 303 is fastened between the rotor body 300. The rotor body 300 includes a rotor core 304. The rotor core 304 and the stopper 303 are sleeved on the rotating shaft 301. The middle part of the rotor core 304 is provided with a groove that runs through both ends. 305, a magnetic steel is embedded in the cavity 305, and the stopper 303 is fixed on both ends of the rotor core 304 through the short-circuit ring 302 to seal and limit the magnetic steel; the stopper 303 at one end is provided with a shape similar to the opening shape of the cavity 305 1. The filling port 307 corresponding to the position, the edge o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com