Vertical silos for dry storage of spent fuel in nuclear power plants

A technology for spent fuel and nuclear power plants, applied in the field of dry storage of spent fuel, which can solve problems such as being easily blocked by foreign objects, insufficient natural ventilation heat transfer, easy to overturn, etc., to avoid external attacks and damage, and eliminate hidden dangers of physical security Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

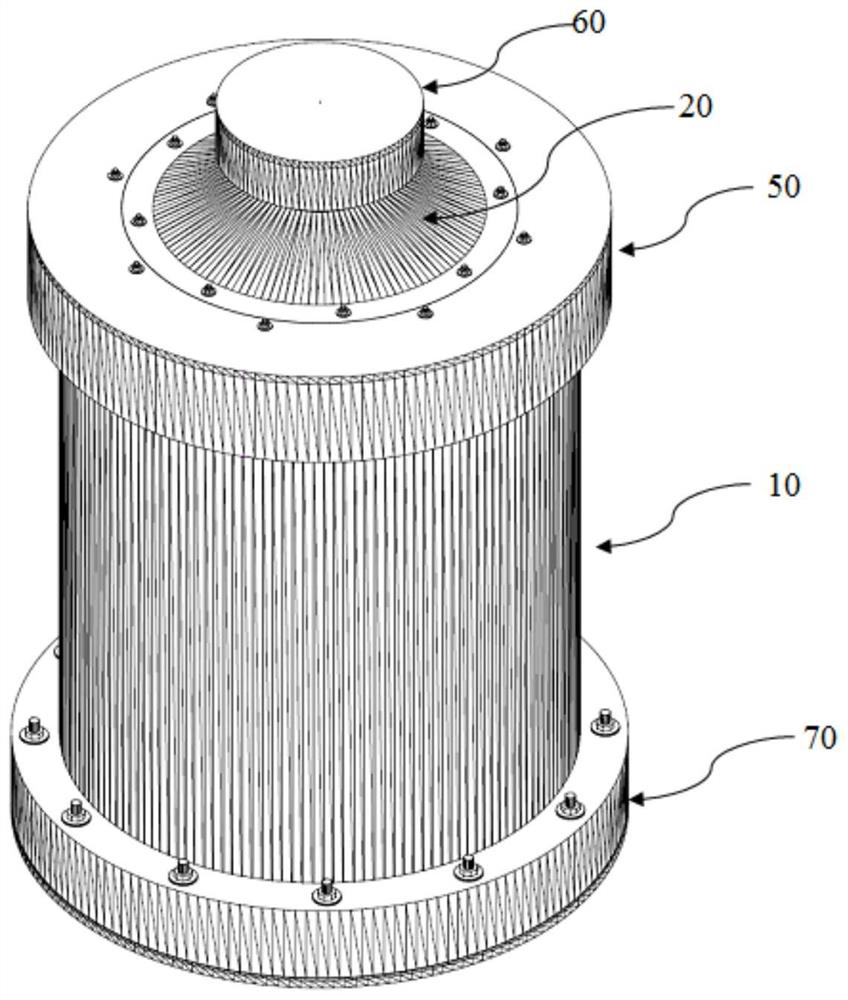

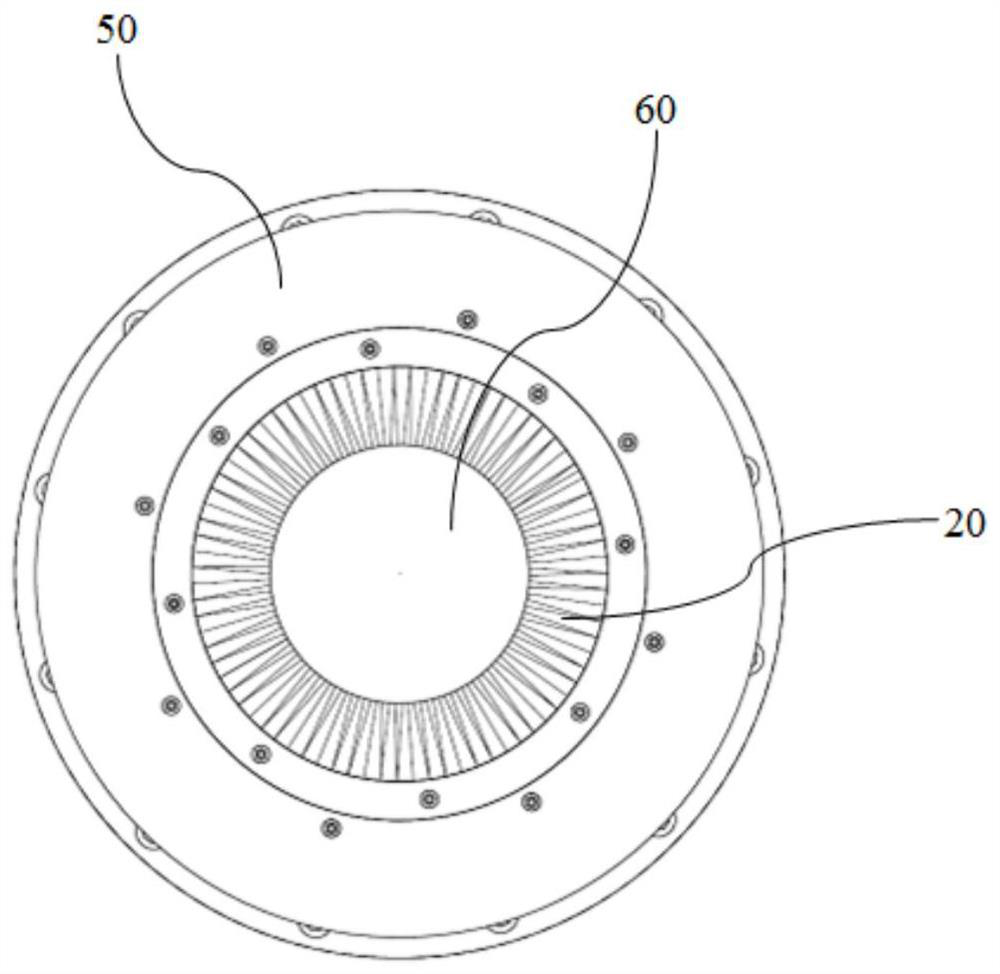

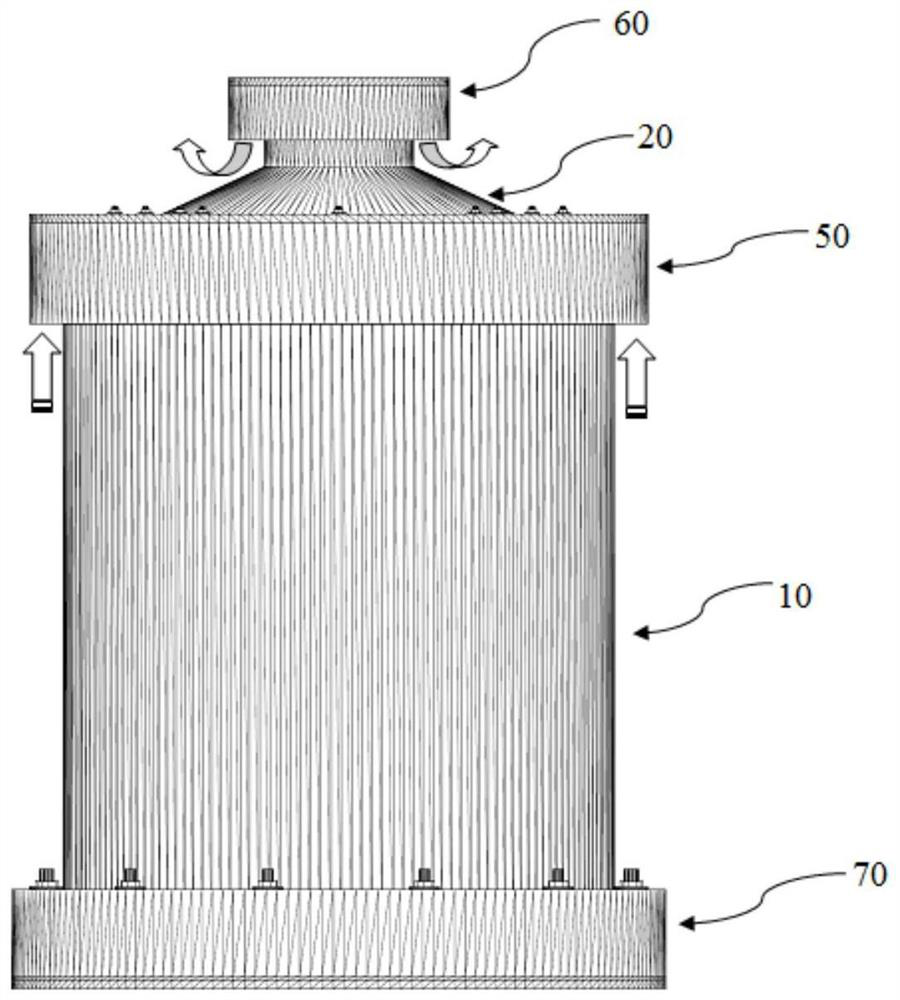

[0059] see Figure 1 to Figure 23 As shown, the vertical silo for dry storage of nuclear power plant spent fuel in the present invention includes a silo 10, a top cover 20 and a bottom plate 30, wherein the silo 10 includes an inner silo 100 and an outer silo 102, and the inner silo 100 There is a first annular cavity 104 between the outer silo 102 and the spent fuel storage tank 40 stored in the silo 10, and there is a second annular cavity 106 between the inner silo 100 and the spent fuel storage tank 40. The inner silo Between the bottom of 100 and the bottom plate 30, there is also an air inlet air channel 108 communicating with the first annular chamber 104 and the second annular chamber 106; the upper area of the silo 10 is provided with an air inlet 110 communicating with the first annular chamber 104, The air inlet 110 is provided with an air inlet protective cover 50, the top cover 20 is provided with an air outlet 200, the air outlet 200 is provided with an air out...

Embodiment approach

[0075] see Figure 20 to Figure 22 As shown, as a preferred embodiment of the present invention, the vertical silo for nuclear power plant spent fuel storage of the present invention further includes a shielding ring 70 arranged at the outer bottom area of the outer silo 102 . The shielding ring 70 is an integral concrete structure and is installed at the outer bottom end of the shell 1020 of the outer silo 102 . The shielding ring 70 is provided with 12 through fixing holes 700. After being inserted into the fixing screw 300 on the bottom plate 30, the shielding ring 70 is directly seated on the skirt 1024 of the external silo 102, and then fixedly connected with matching nuts, so that The shielding ring 70, the outer silo 102 and the inner silo 100 form an integral structural unit.

[0076] Since the circular air inlet air channel 108 between the bottom of the inner silo 100 and the bottom plate 30 adopts an unshielded full-range ventilation design, for the bottom area, o...

Embodiment 2

[0091] see Figure 24As shown, it is a schematic diagram of the second embodiment of the vertical silo for dry storage of nuclear power plant spent fuel in the present invention. The bottom of the cylinder 1000 is evenly spaced with a plurality of through holes 1000a, and the plurality of through holes 1000a constitute the air inlet air channel between the bottom of the inner silo 100 and the bottom plate 30.

[0092] The inner wall of the cylinder 1000 is provided with a steel lining 1004, and a vertical rib 1002 is welded on the steel lining 1004. The bottom of the vertical rib 1002 extends to the bottom plate 30 and is fixed by welding with the bottom plate 30. The top interface of the vertical rib 1002 Below the top interface of the cylinder 1000 , when the top cover (not shown in the figure) is used for sealing, the bottom of the top cover is nested inside the cylinder 1000 and supported on the top of the vertical rib 1002 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com