Ultrasonic wave sensor

A sensor and ultrasonic technology, applied in the field of ultrasonic sensors, can solve the problems of high installation height of trucks, achieve the effects of reducing accidents, solving short-distance blind spots, and solving beam angle restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

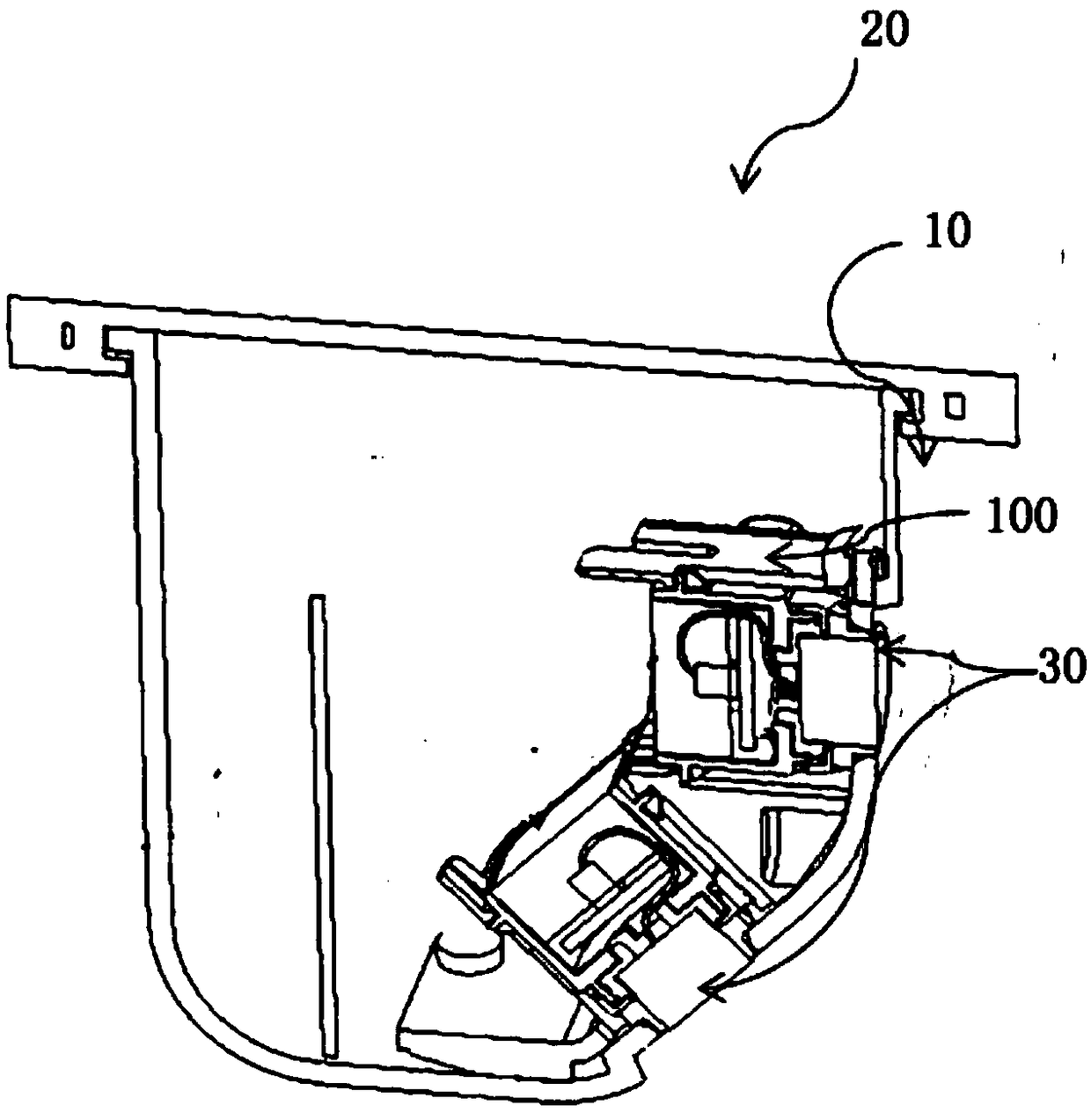

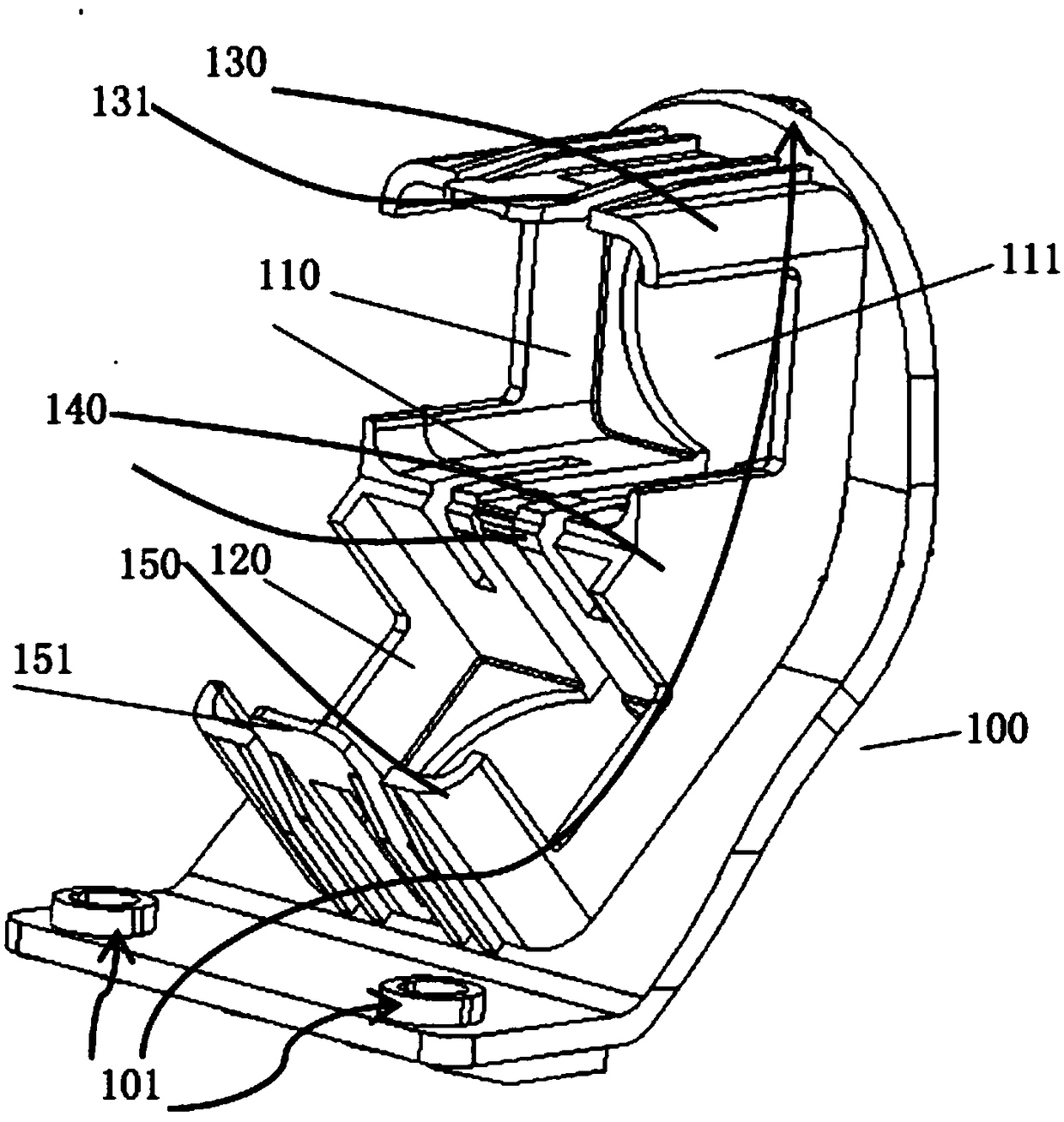

[0022] Such as Figure 1-3 As shown, an ultrasonic sensor of the present invention includes a sensor housing 10, the surface of the sensor housing 10 is provided with a strip-shaped groove 11, and a probe installation port ( 12, 13).

[0023] The sensor housing 10 is provided with a sensor bracket 100 inside. The sensor bracket 100 is used to install the ultrasonic sensor and maintain the relative position between the ultrasonic sensors. The sensor bracket 100 includes a mounting side and a fixed side, and the mounting side is in contact with the sensor housing. The sensor bracket 100 is installed and fixed on the sensor housing 10, for example, can be fixed by screws, and fixing holes 101 can be provided at the upper and lower ends of the sensor bracket 100, and fixed on the sensor housing 10 through the fixing holes 101 by screws.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com