Compressor and air suction silencer thereof

A muffler and compressor technology, which is applied in the direction of machines/engines, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of poor refrigeration effect and low performance of compressors, so as to reduce temperature, improve energy efficiency ratio, and improve Effect of Gas Transmission Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

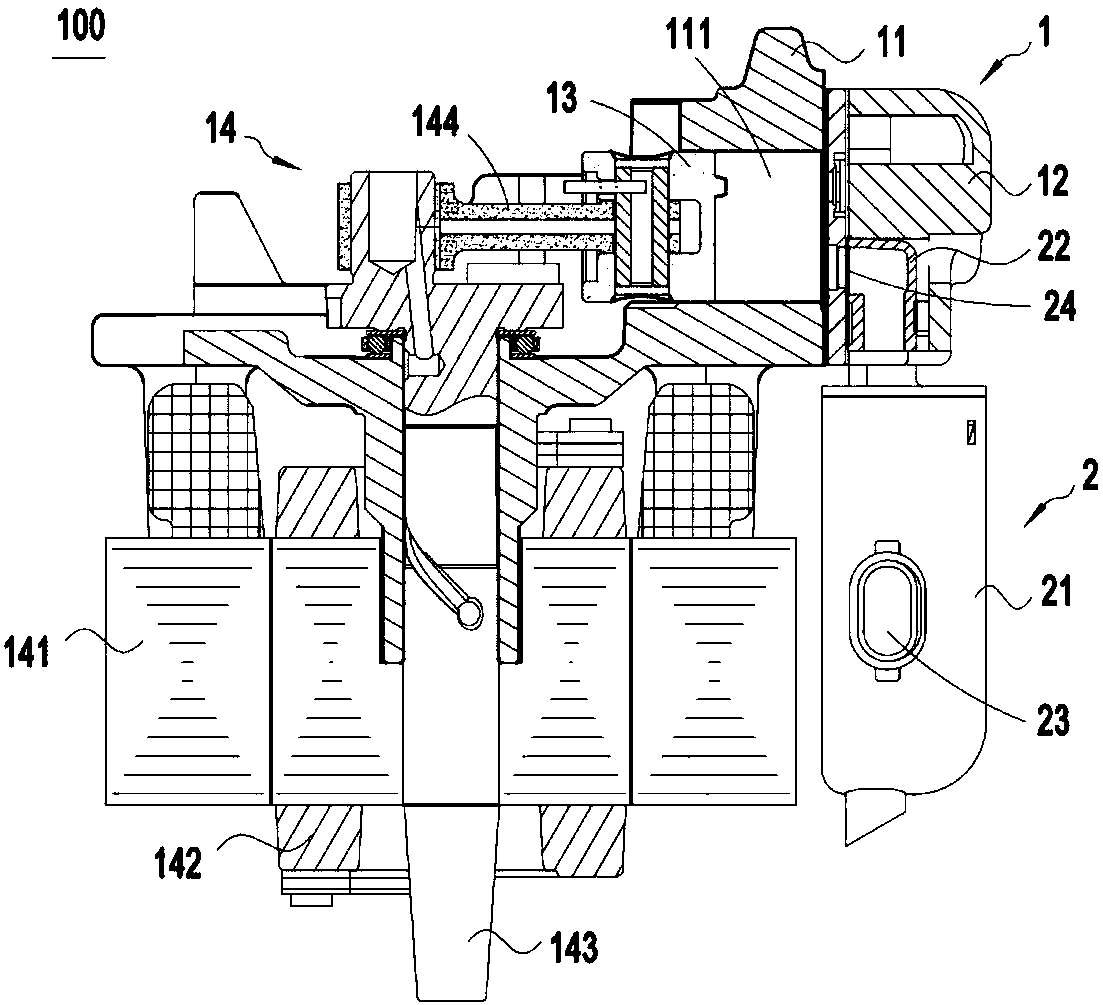

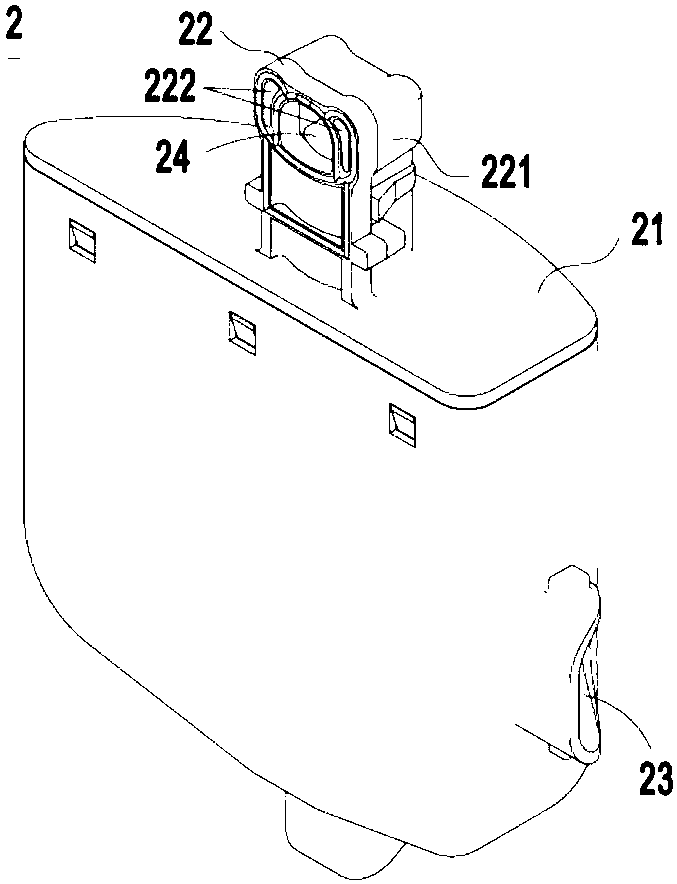

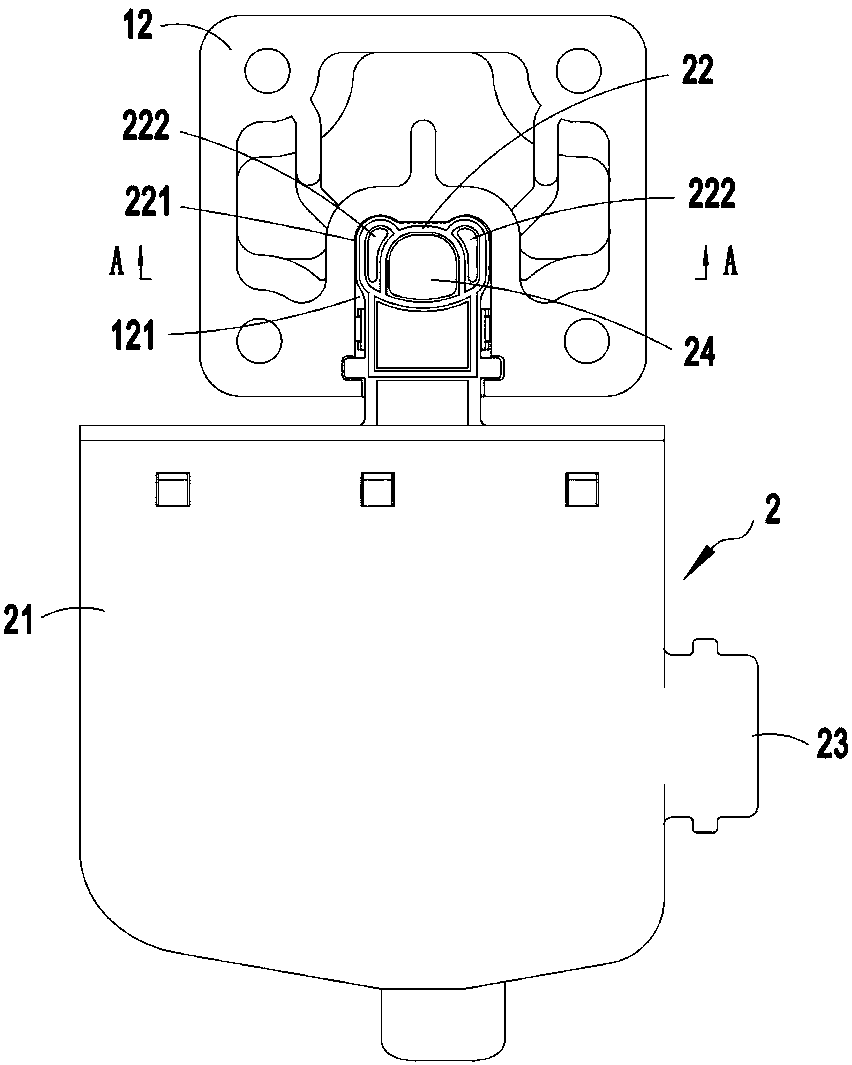

[0027] According to attached figure 1 The compressor 100 shown includes a compression cylinder 11, a cylinder head 12 arranged on the compression cylinder 11, a drive mechanism 13 for driving the compression cylinder 11, and a muffler 2 for delivering refrigerant to the interior of the compression cylinder 11. . A compression chamber 111 is arranged inside the compression cylinder 11, and a piston 13 is arranged in the compression chamber 111. The piston 13 can move back and forth in the compression chamber 111 to carry out compression operations. The driving mechanism 14 includes a stator 141, a rotor 142 arranged in the stator 141, A crankshaft 143 fixedly connected to the rotor 142 , a connecting rod 144 hinged on the crankshaft 143 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com