Bathroom fabricated chassis

A bathroom and prefabricated technology, applied in special buildings, small buildings, building components, etc., can solve the problems of inability to reuse reclaimed water, waste of domestic water, and difficult maintenance of pipelines, so as to dilute the construction cost and shorten the construction time , the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

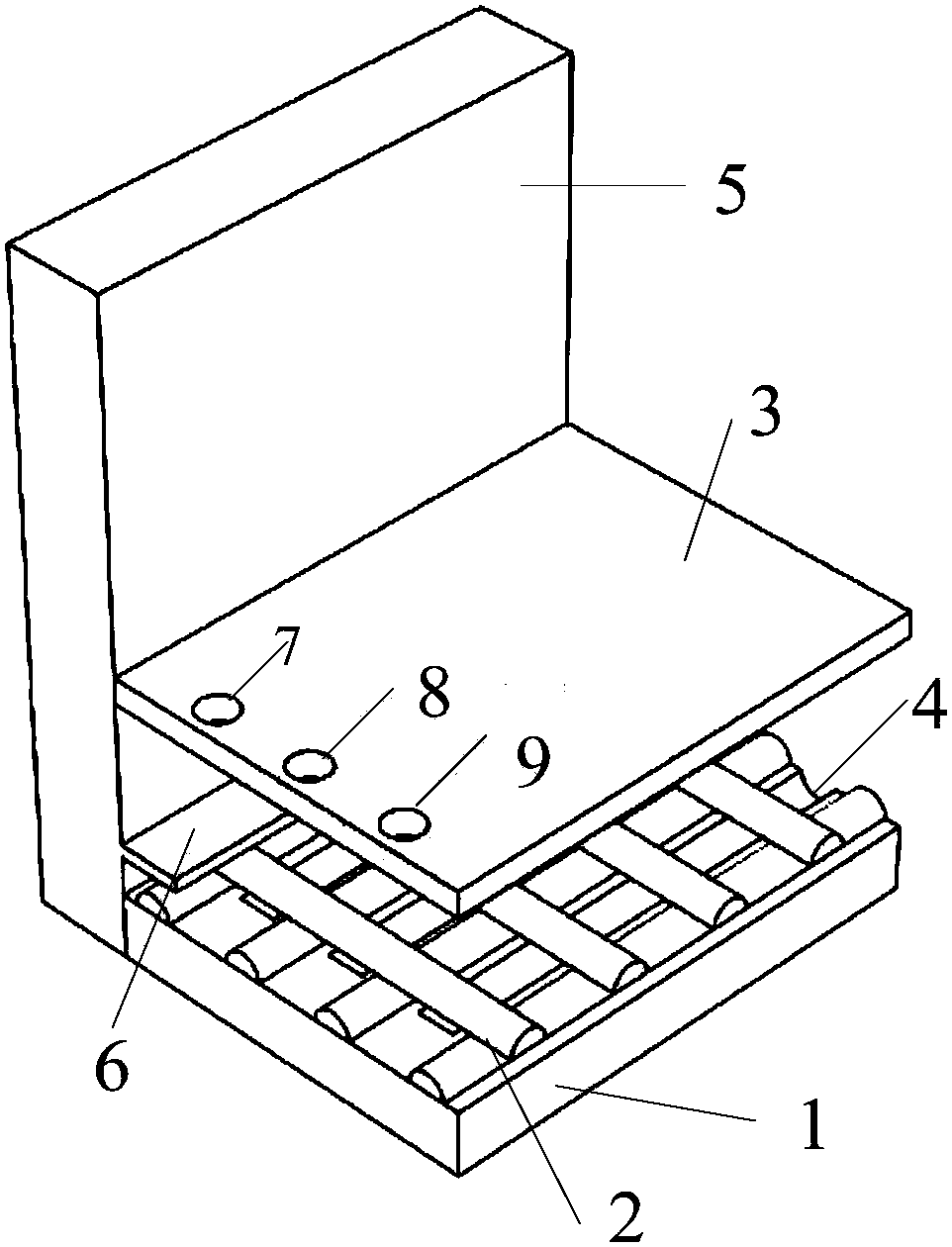

[0045] This embodiment provides a bathroom assembly chassis, which includes a waterproof integral base plate 1, a skeleton 2, a surface floor 3 and three pipes (not shown in the figure);

[0046] The waterproof integral bottom plate 1 is a flat plate, and the flat plate is provided with a pipe installation groove 4;

[0047] The skeleton 2 is installed on the waterproof integral bottom plate 1, and the surface floor 3 is fixed on the skeleton 2 by adjusting bolts;

[0048] The surface floor 3 is provided with three openings, which are respectively used for installing the toilet 9, the sink 8 and the floor drain 7;

[0049] The three pipelines are installed in the pipeline installation groove 4, and one end of the three pipelines is respectively connected to the water outlet of the toilet 9, the sink 8 and the floor drain 7, and the other ends are connected to the drainage standpipe of the toilet;

[0050] The material of the waterproof integral bottom plate is UPVC;

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com