A structural panel containing bamboo strips and its design method

A technology of structural boards and bamboo strips, applied in design optimization/simulation, building components, building structures, etc., can solve the problems of not fully utilizing the performance of bamboo, and the lack of clear determination and calculation methods for the bearing capacity of bamboo-containing structures, etc., to achieve Easy industrial hoisting and transportation, ensuring durability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

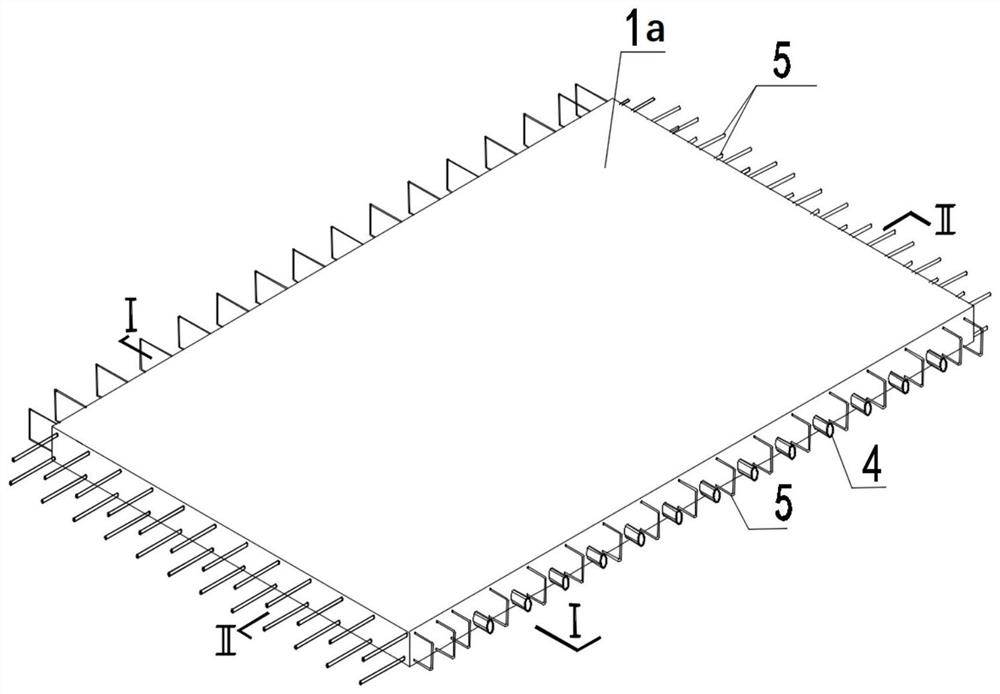

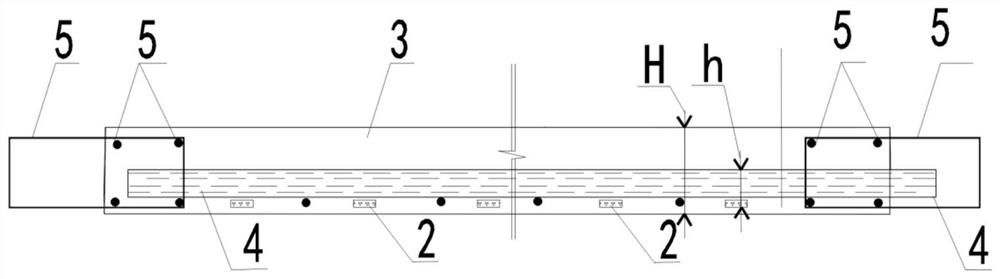

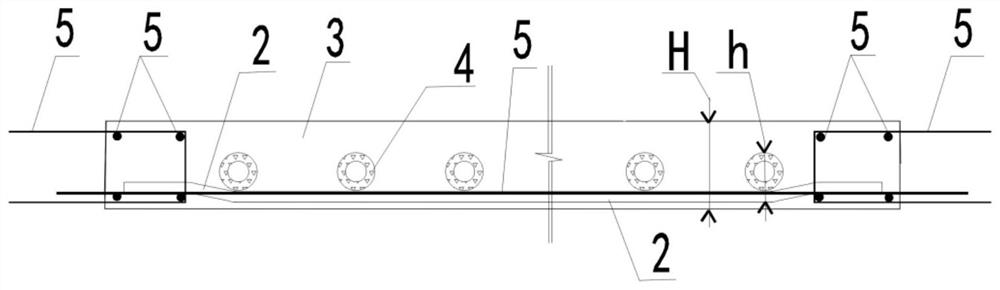

[0058] Such as Figure 1-3 As shown, the floor 1a of this case is a flat body with two upper and lower surfaces and four connecting surfaces, which consists of round bamboo section 4, bamboo slice 2, steel bar 5 and concrete 3, specifically the short direction of the floor (i.e. I-I Section direction) adopts round bamboo section 4 to bear the force, and the long direction of the floor (i.e. II-II section direction) adopts bamboo slice 2+reinforcing bar 5 to bear the force, and the connection joint around the described structure floor slab contains reinforcing bar 5, and reinforcing bar 5 To form the stirrup skeleton, the components include round bamboo segments 4 and bamboo slices 2 + steel bars 5 to form a grid that is a square grid, and the grid is placed in the thickness of the protective layer near the bottom of the slab, wrapped by concrete 3, and does not expose the surface. And the round bamboo section and the bamboo slices 2 form the grid skeleton and are included in t...

Embodiment example 2

[0086] Such as Figure 4-6 As shown, the floor 1a of this case has two upper and lower surfaces and a flat body with four connecting surfaces, which consists of round bamboo segments 4, bamboo slices 2, steel bars 5 and concrete 3, specifically in the short direction of the floor (i.e. I-I section direction) adopts round bamboo section 4 to bear the force, and the long direction of the floor slab (that is, the direction of the II-II section) adopts the force of bamboo slice 2, and the connection joints around the structure floor slab contain reinforcement bars 5, and the reinforcement bars 5 form the stirrup skeleton , the component consists of round bamboo segments 4+bamboo slices 2. The grid is a square grid. The grid is placed in the thickness of the protective layer close to the bottom of the slab, and is wrapped by concrete 3 without protruding from the surface. The round bamboo segments and bamboo slices 2. The surrounding frame of the grid is contained in the frame of s...

Embodiment example 3

[0095] Such as Figure 7-9 As shown, the wall panel 1b of this case has two flat surfaces and four connecting surfaces, which are composed of round bamboo segments 4, bamboo slices 2, steel bars 5, section steel 6 and concrete 3, specifically the vertical wall panels. Round bamboo section 4 is arranged to replace steel bar and concrete (effect is to bear pressure and resist horizontal shear force, prevent wallboard from cracking), and the horizontal direction of wallboard is arranged on the two outer sides of vertical vertical round bamboo section 4 close to the surface Horizontal bamboo slices 2 (a total of two layers of bamboo slices) replace the steel bars to resist tension and prevent cracking. The joints around the structural wall panels contain steel bars 5, and the steel bars 5 form a skeleton. The components include round bamboo segments 4 and bamboo slices. 2. The grid is a square grid (full bamboo grid). The grid is placed in the center of the wall panel so that it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com