Energy-saving environmental-friendly external wall material and preparation method thereof

An energy-saving and environmentally friendly exterior wall technology, applied in the field of building materials, can solve the problems of unsatisfactory thermal insulation effect and limited variety of thermal insulation materials, and achieve the effects of not easy to fall off and crack, good thermal insulation performance, and protect the main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A preparation method of an energy-saving and environment-friendly exterior wall material, including the following process steps: (1) Mix fly ash and quicklime evenly, add water and stir for 3-5 minutes, then add vitrified microbeads and perlite composite aggregate , stirred for 15-30 minutes to prepare mixed slurry A; (2) Mix starch, sodium hydroxide, and cellulose C palmitate evenly, stir for 3-5 minutes, then add silicone emulsion, and stir for 10-15 minutes to prepare Obtain mixed slurry B; (3) Pour mixed slurry B, wood fiber and epoxy resin into mixed slurry A, stir for 15-25 minutes, then add water retaining agent and anti-cracking agent, stir for 10-15 minutes, wait for mixing After uniformity, detection and packaging.

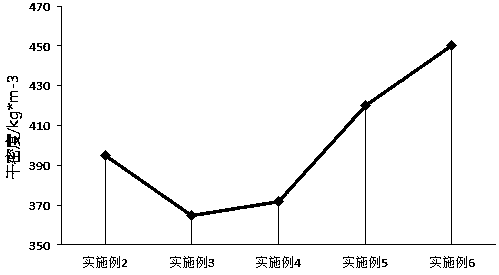

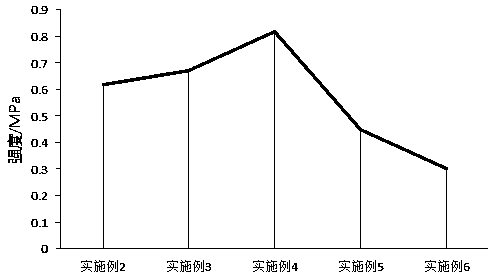

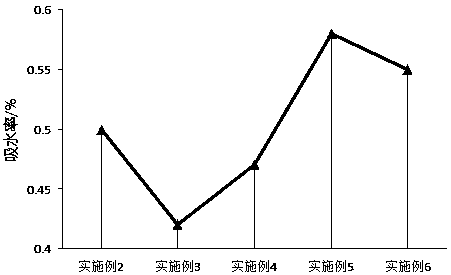

Embodiment 2

[0031] An energy-saving and environment-friendly exterior wall material, its ingredient ratio is: 38 parts of fly ash, 45 parts of quicklime, 15 parts of vitrified microbeads, 15 parts of perlite, 5 parts of starch, 8 parts of cellulose C palmitate, wood fiber 4.5 parts, 22 parts of epoxy resin, 32 parts of silicone emulsion, 3 parts of sodium hydroxide, 3 parts of water retaining agent and 2 parts of anti-cracking agent.

Embodiment 3

[0033] An energy-saving and environment-friendly exterior wall material, its ingredient ratio is: 35 parts of fly ash, 32 parts of quicklime, 7 parts of vitrified microbeads, 18 parts of perlite, 3 parts of starch, 6 parts of cellulose C palmitate, wood fiber 3 parts, 10 parts of epoxy resin, 30 parts of silicone emulsion, 2 parts of sodium hydroxide, 2 parts of water retaining agent and 3 parts of anti-cracking agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com