Preparation method of food-grade aluminum-free disodium dihydrogen pyrophosphate with low gas emission volume

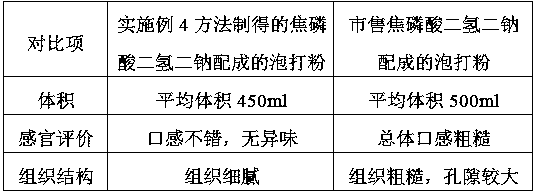

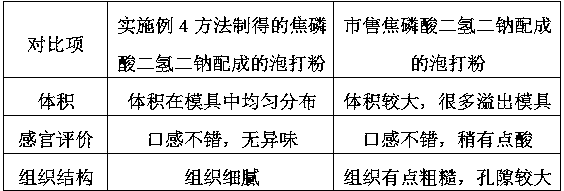

A food-grade disodium dihydrogen pyrophosphate technology, which can be used in food drying, chemical instruments and methods, and food ingredients as fluffing agents, etc. It can solve the problems of unrefined tissue structure, large volume, rough taste, etc., and achieve high-quality taste , Uniform size, smooth gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, a preparation method of food-grade aluminum-free low-gas generation disodium dihydrogen pyrophosphate, the method uses phosphoric acid and sodium hydroxide as raw materials, and the specific steps are as follows:

[0020] (1) Raw material preparation: After filtering phosphoric acid, adjust the temperature to 45°C and concentration to 51°Bé; after filtering sodium hydroxide, adjust the temperature to 45°C and concentration to 30°Bé; the mass content of raw phosphoric acid is 80%, arsenic≤0.0002 %, the mass content of sodium hydroxide is 98%.

[0021] (2) Neutralization: Add phosphoric acid to the neutralization tank, start stirring, add additives calcium carbonate and potassium dihydrogen phosphate before adding sodium hydroxide, the additives are added in an amount of 0.1% of the mass of phosphoric acid, and the additives After dissolving completely, open the sodium hydroxide feed valve, control the sodium hydroxide feed rate to be 0.3kg / s; The pH value ...

Embodiment 2

[0024] Embodiment 2, a preparation method of food-grade aluminum-free low-gas generation disodium dihydrogen pyrophosphate, the method uses phosphoric acid and sodium hydroxide as raw materials, and the specific steps are as follows:

[0025] (1) Raw material preparation: after filtering phosphoric acid, adjust the temperature to 60°C and concentration to 53°Bé; after filtering sodium hydroxide, adjust the temperature to 60°C and concentration to 40°Bé; the mass content of raw phosphoric acid is 85%, arsenic ≤ 0.0002 %, the mass content of sodium hydroxide is 99.5%.

[0026] (2) Neutralization: Add phosphoric acid to the neutralization tank, start stirring, add additives calcium carbonate and potassium dihydrogen phosphate before adding sodium hydroxide, the additives are added in an amount of 0.5% of the mass of phosphoric acid, and the additives After dissolving completely, open the sodium hydroxide feed valve, control the sodium hydroxide feed rate to be 0.4kg / s; The pH va...

Embodiment 3

[0029] Embodiment 3, a preparation method of food-grade aluminum-free low-gas generation disodium dihydrogen pyrophosphate, the method uses phosphoric acid and sodium hydroxide as raw materials, and the specific steps are as follows:

[0030] (1) Raw material preparation: After filtering phosphoric acid, adjust the temperature to 50°C and concentration to 52°Bé; after filtering sodium hydroxide, adjust the temperature to 50°C and concentration to 35°Bé; the mass content of raw phosphoric acid is 83%, arsenic≤0.0002 %, the mass content of sodium hydroxide is 99%.

[0031] (2) Neutralization: Add phosphoric acid to the neutralization tank, start stirring, add additives calcium carbonate and potassium dihydrogen phosphate before adding sodium hydroxide, the amount of calcium carbonate added is 0.3% of the mass of phosphoric acid, dihydrogen phosphate The amount of potassium added is 0.1% of the mass of phosphoric acid. After the auxiliary agent is completely dissolved, open the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com