Freight vehicle material leveling machine

A technology of leveling machine and materials, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem of unsatisfactory material leveling effect, and achieve the effect of increasing leveling area, high leveling efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

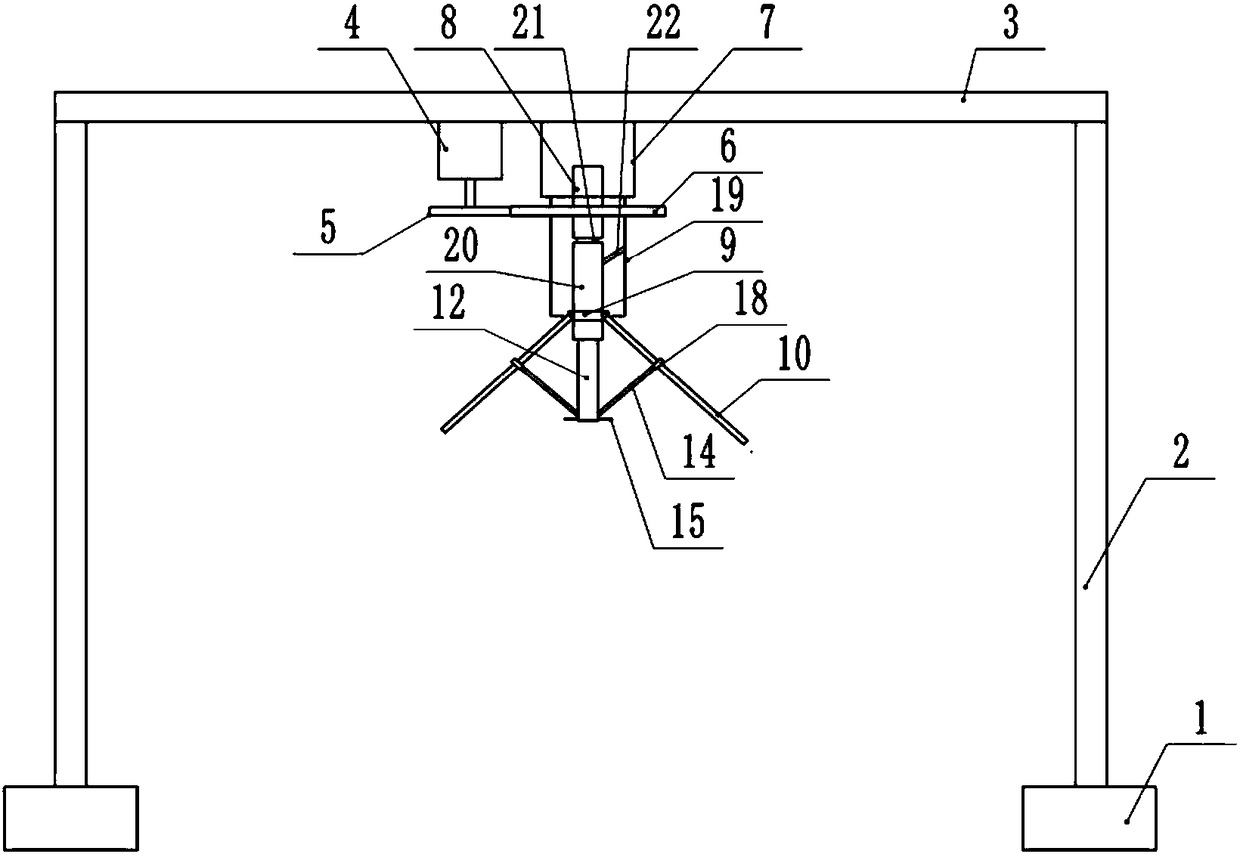

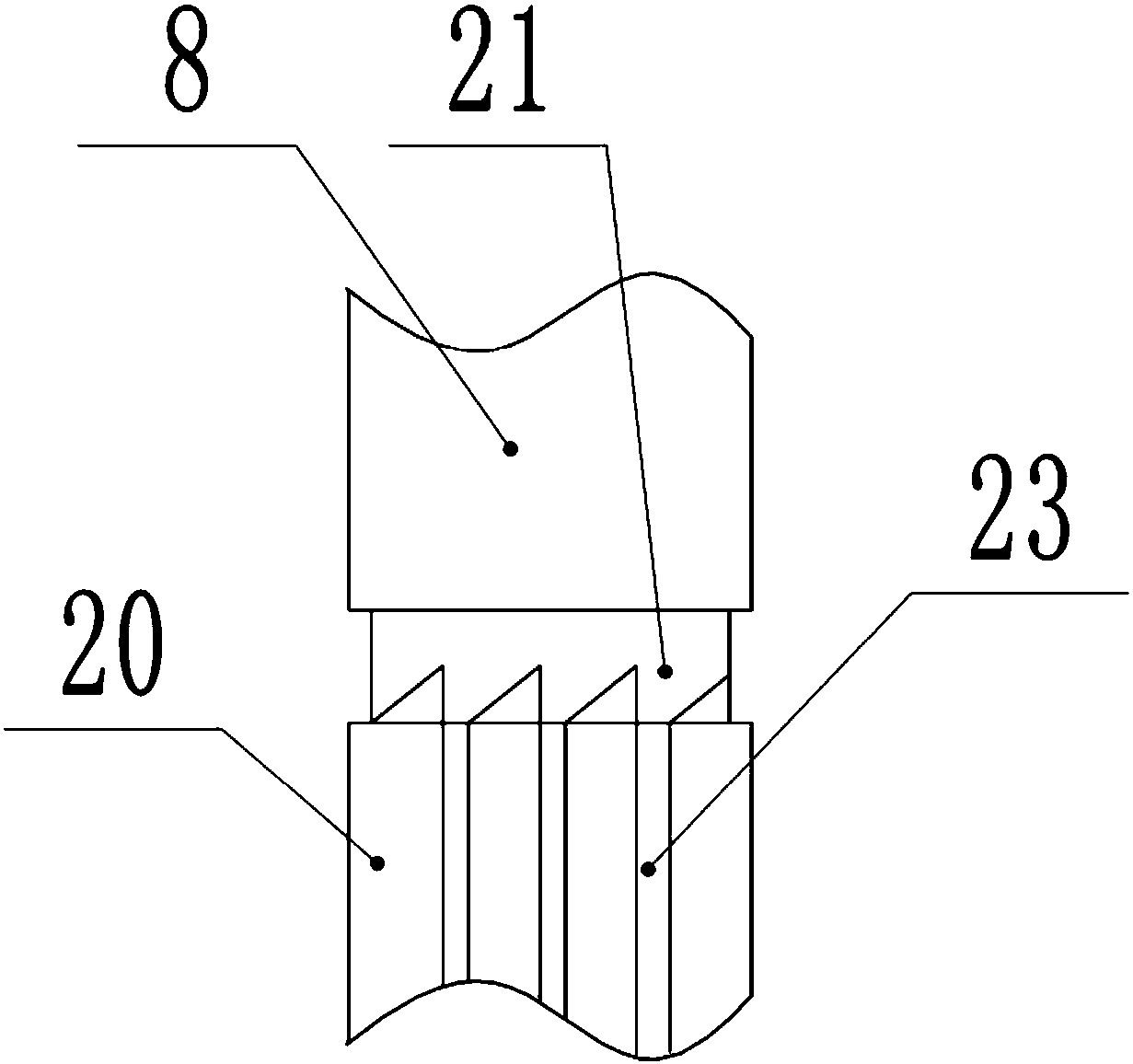

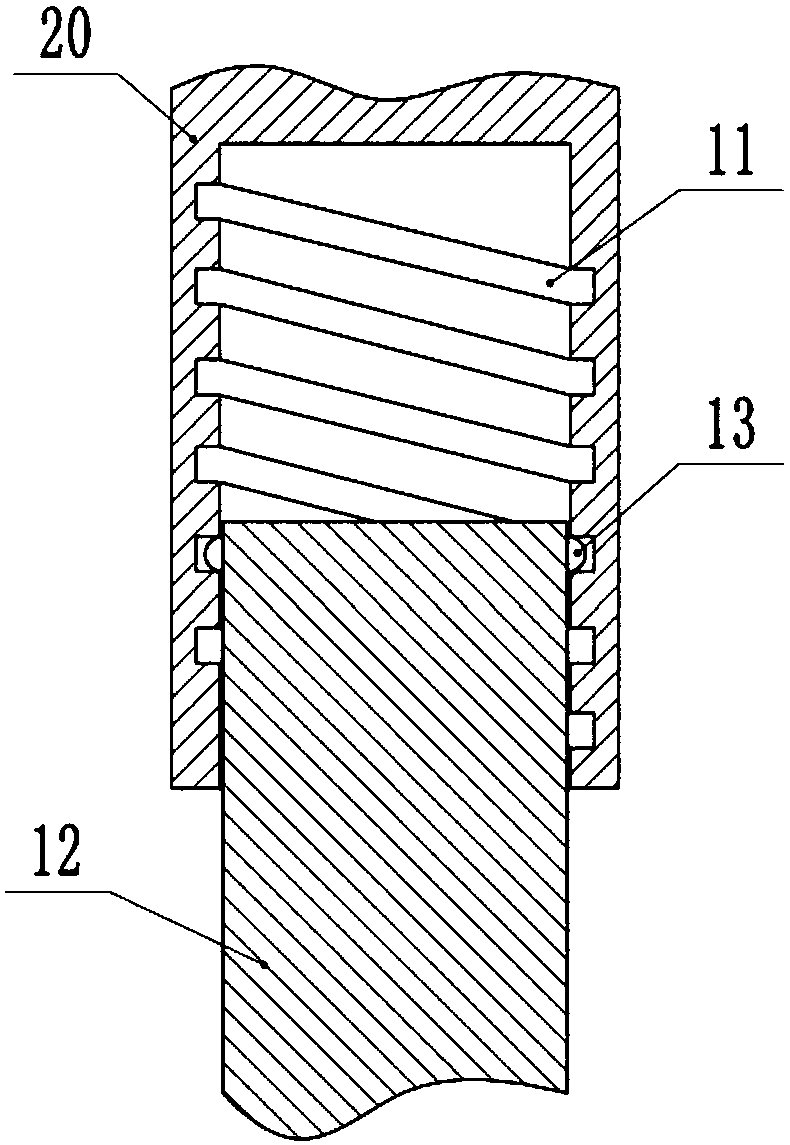

[0025] Such as figure 1 As shown, the material leveling machine for freight vehicles includes two support platforms 1, and the distance between the two support platforms 1 can be used for freight vehicles to pass through. The two support platforms 1 are respectively equipped with pillars 2 through bolts. A crossbeam 3 is installed between them, and a servo motor 4 with the output shaft facing down is installed on the crossbeam 3. A first gear 5 is installed on the lower end of the output shaft, and a first bracket 7 is installed on the crossbeam 3 at the right side of the servo motor 4. , the lower end of the first bracket 7 is equipped with a first bearing seat, a bearing is installed in the first bearing seat, a second gear 6 is installed on the inner ring of the bearing, the second gear 6 is preferably a shaft gear, the first gear 5 and the second The gears 6 are meshed, and the axis of the second gear 6 is threadedly installed with a screw mandrel 8; as figure 2 As shown...

Embodiment 2

[0028] Such as Figure 4 As shown, on the basis of Embodiment 1, an elastic cover 16 is installed on the second bracket 19. When the scraper 10 is opened outward, the cover 16 is supported by the scraper 10. When the scraper 10 is vertically When the rod 20 closes and closes, the casing 16 shrinks under the action of elasticity. By installing the casing 16, it can prevent the scraper rod 10 from splashing when leveling the materials in the freight car, and at the same time prevent the generation of dust and protect the environment; Install slide rails on 2, install rollers on both sides of the beam 3 in contact with the pillar 2, the rollers can slide in the slide rails, install the cylinder 17 at the lower end of the pillar 2, connect the piston rod of the cylinder 17 to the beam 3, and control the cylinder 17 enables the crossbeam 3 to slide up and down on the pillar 2, and by adjusting the height of the crossbeam 3, the freight cars of different heights can be leveled, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com