A six-suspension module medium-speed maglev vehicle running mechanism

A traveling mechanism and maglev technology, applied in vehicle components, electric vehicles, electric traction, etc., can solve the problems of reducing train-rail coupling vibration, insufficient effective carrying capacity, and failing to reach the medium speed range, so as to reduce the train-rail coupling. Vibration, convenient for daily use and maintenance, and the effect of improving suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

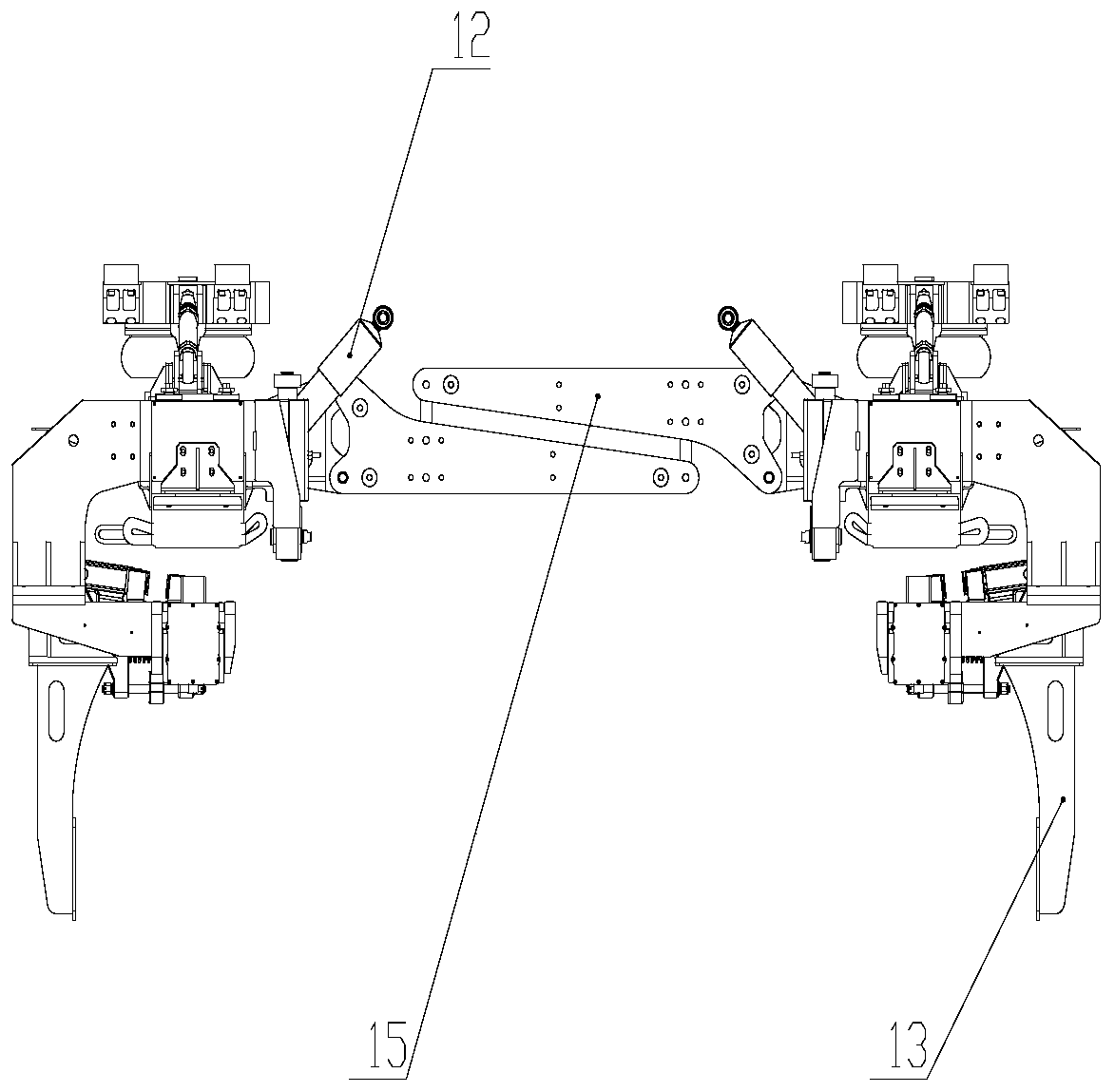

[0018] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

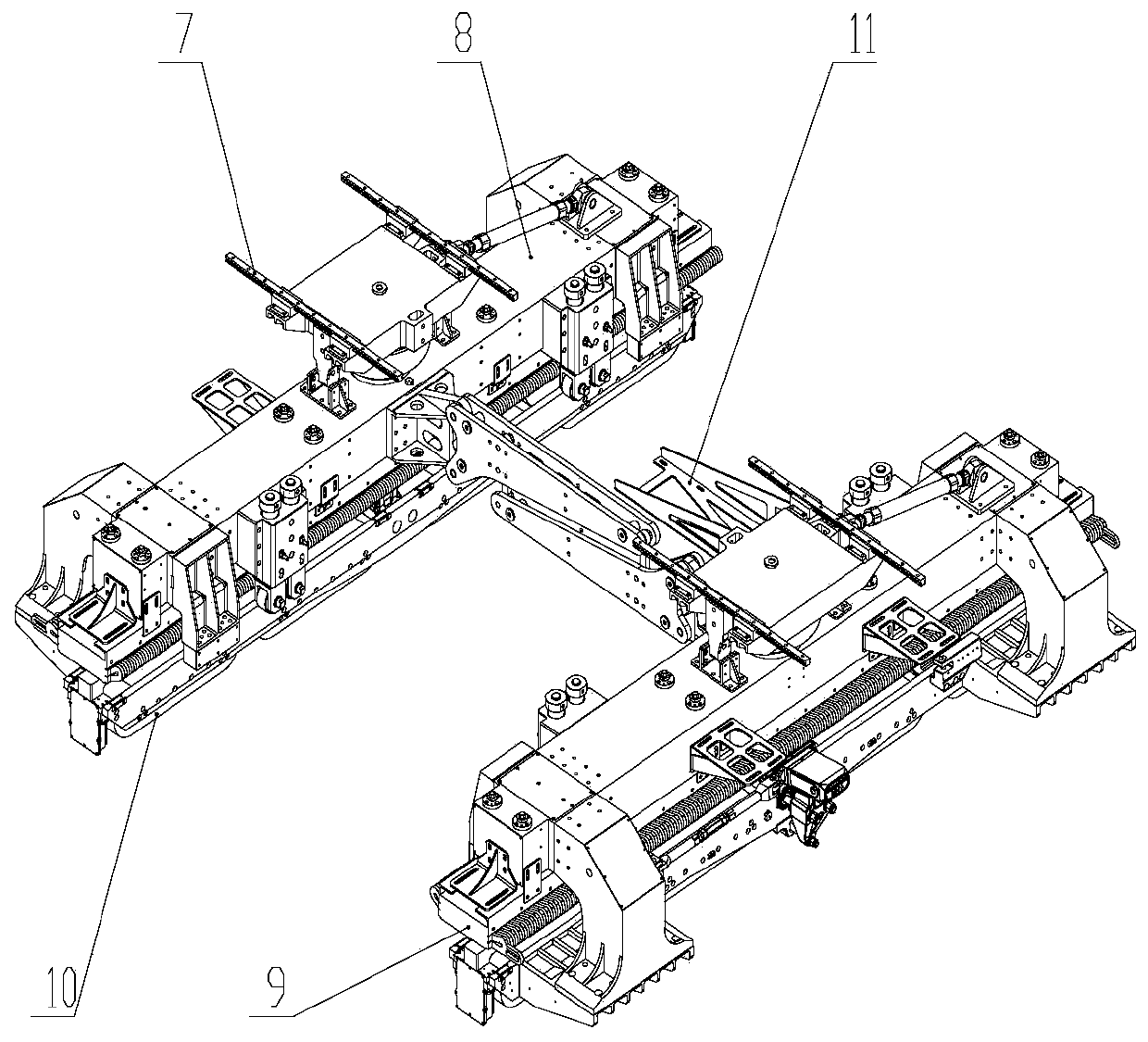

[0019] A six-suspension-module medium-speed maglev vehicle running mechanism of the present invention adds a suspension module to the existing five-suspension-module medium-speed maglev vehicle running mechanism, and cancels the forced guide mechanism, so the suspension and With excellent traction performance, compact and reasonable structure, and low power interaction with the line, it can meet the needs of medium-speed applications with a speed of not less than 180km / h.

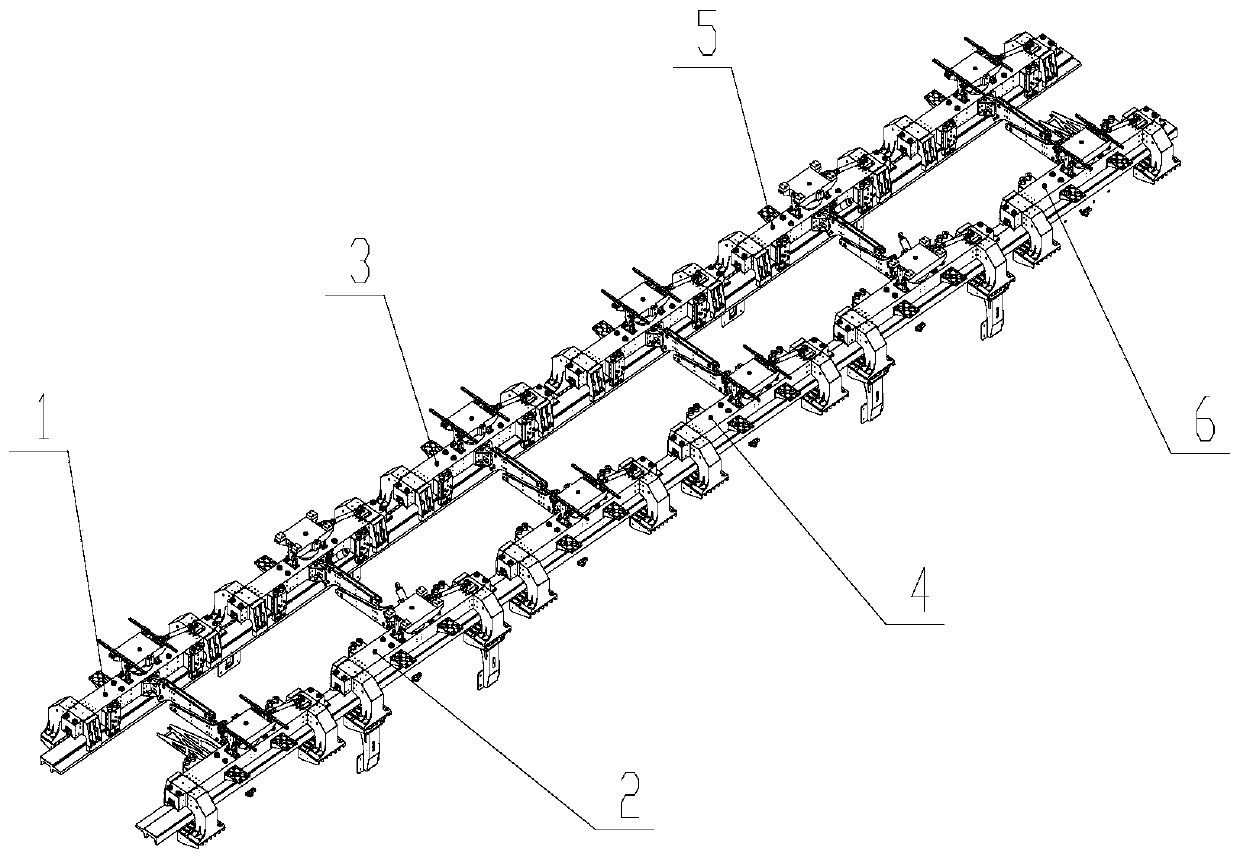

[0020] Such as figure 1 As shown, the present invention includes six suspension modules arranged longitudinally along the vehicle body; they are sequentially recorded as: the first suspension module 1, the second suspension module 2, the third suspension module 3, the fourth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com