Automatic edge aligning device of shell fabric compounding machine

A laminating machine, automatic technology, applied in the direction of lamination auxiliary operation, control lamination, lamination, etc., can solve the problems of inability to shrink, affect the effect of lamination, unable to adjust the position of fabric width, etc. edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

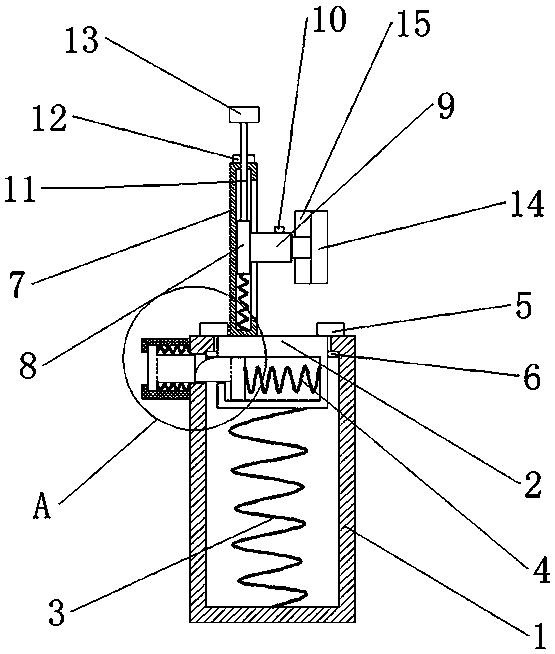

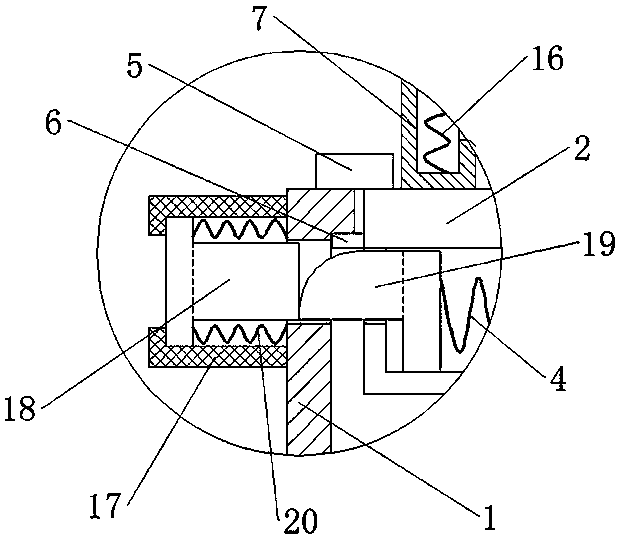

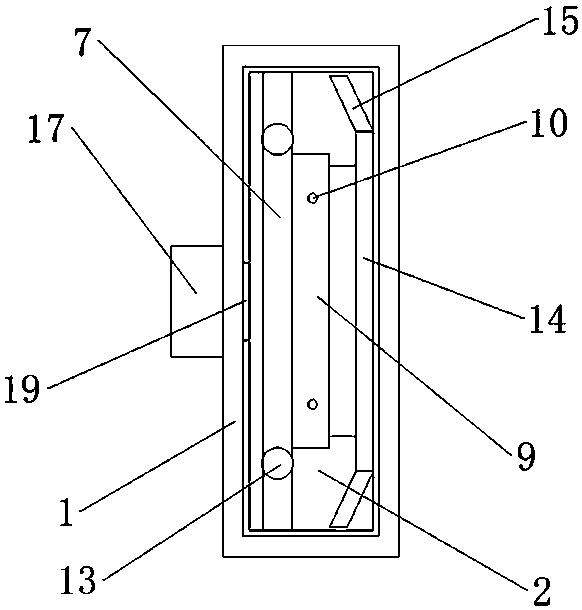

[0030] see Figure 1-3 , an automatic edge-aligning device for a fabric compounding machine, comprising a shell 1 with an upward opening, a base box 2 is slidably connected to the inside of the shell 1, a pair of limit blocks 6 are fixedly connected to the base box 2, and the lower end of the base box 2 is connected to the shell 1 A tension spring 3 is connected between the inner bottom plates of the shell, a first through hole is opened on the side wall of the shell 1, a second through hole matching the first through hole is opened on the side wall of the base box 2, and the base The inside of the box 2 is slidably connected with a locking block 19, one end of the locking block 19 passes through the second through hole and the first through hole in turn, and the other end of the locking block 19 is connected to the inner wall of the base box 2 with a first compression The spring 4 is fixedly connected with a button frame 17 corresponding to the first through hole on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com