LLC Sensorless Synchronous Rectification Control Method Based on Phase Shift Angle Feedforward

A technology of synchronous rectification and control method, which is applied in the direction of control/adjustment system, instrument, output power conversion device, etc. It can solve the problems of not considering the change of the maximum gain value, low decoupling accuracy, and increased system hardware cost, etc., to achieve Solve the hysteresis of synchronous rectification control, ensure safe operation, and reduce hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

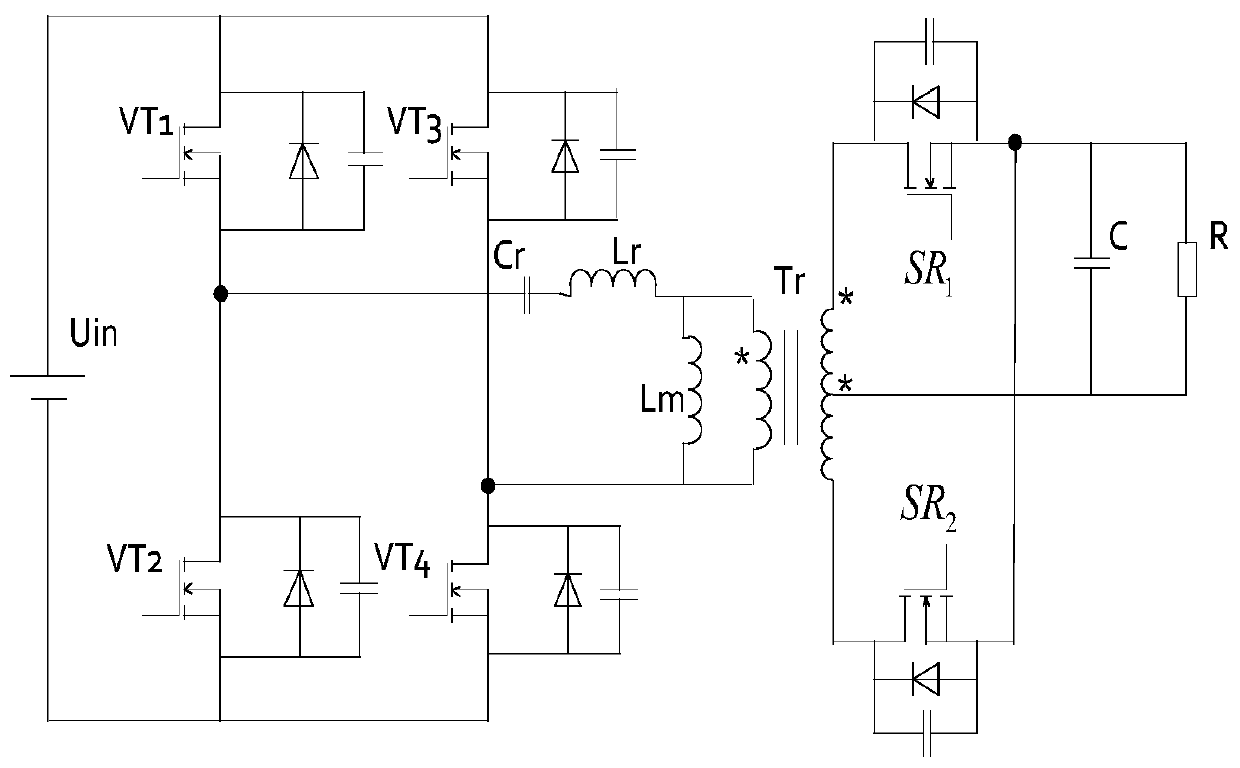

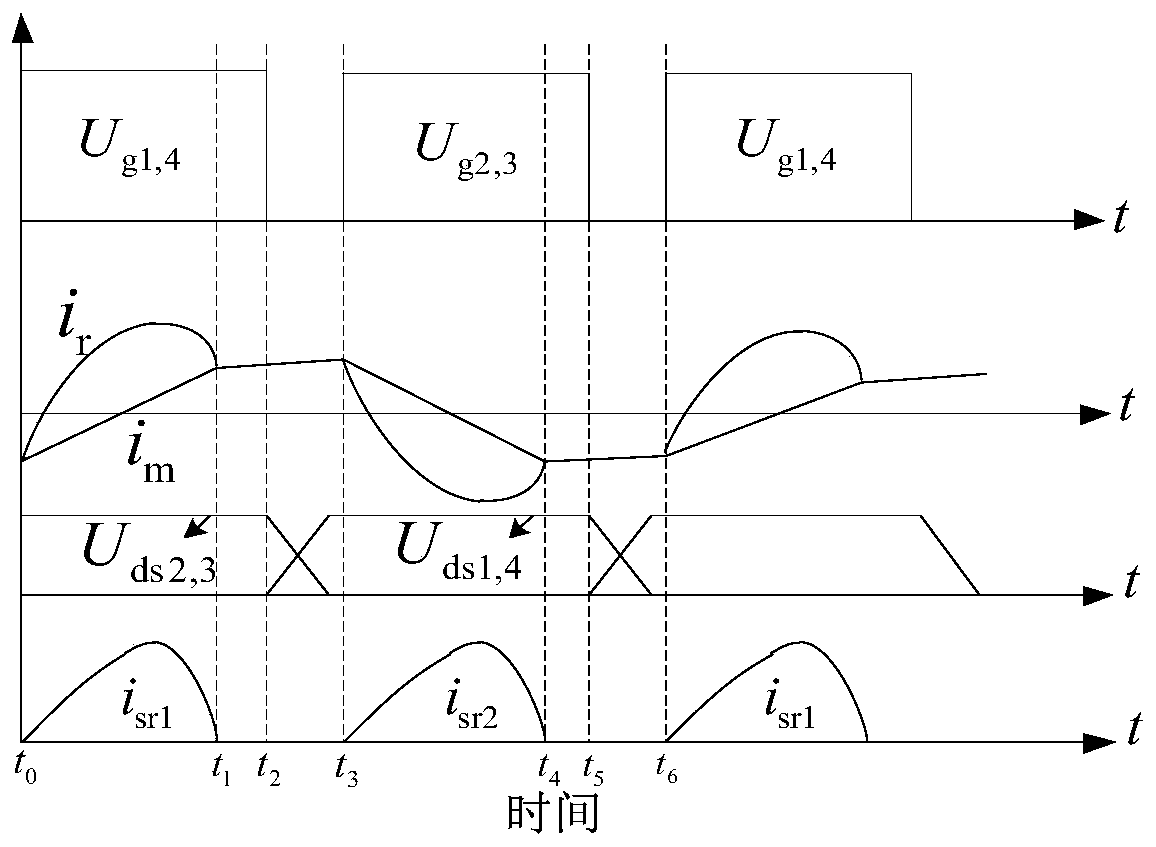

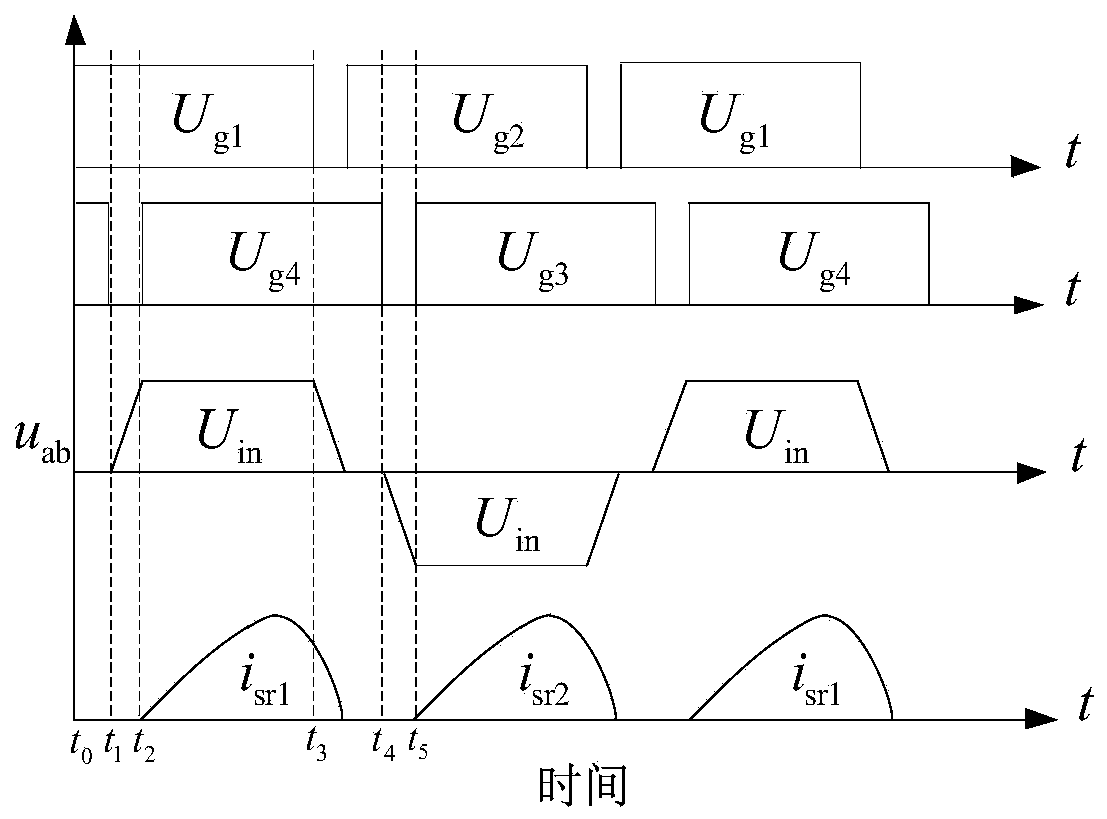

[0056] figure 1 It is a circuit scheme of the present invention. u in for the input power supply, VT 1 -VT 4 is the primary switch tube of the transformer, C r is the resonant capacitor, L r is the resonant inductance, L m is the magnetizing inductance, T r For high frequency transformers, SR 1 and SR 2 It is a synchronous rectifier tube, C is a filter capacitor, and R is a load. When the frequency conversion control in the hybrid control is adopted, the switching tube VT 1 with VT 4 Simultaneously on and off, the switch tube VT 2 with VT 3 Simultaneously on and off, the switching tubes of the same bridge arm are complementary conducting, and the duty cycle of each switching tube is fixed at 50% after ignoring the dead time, by changing the switching frequency f s to adjust the output voltage. The corresponding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com