Field emission high-precision double-gate structure for reducing electron interception and its installation method

A double grid structure, field emission technology, applied in the field emission field, can solve the problems of low grid transmittance, difficulty in achieving high-precision alignment, limited increase in physical transmittance, etc., so as to improve alignment problem and simple structure. , the effect of improving the transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

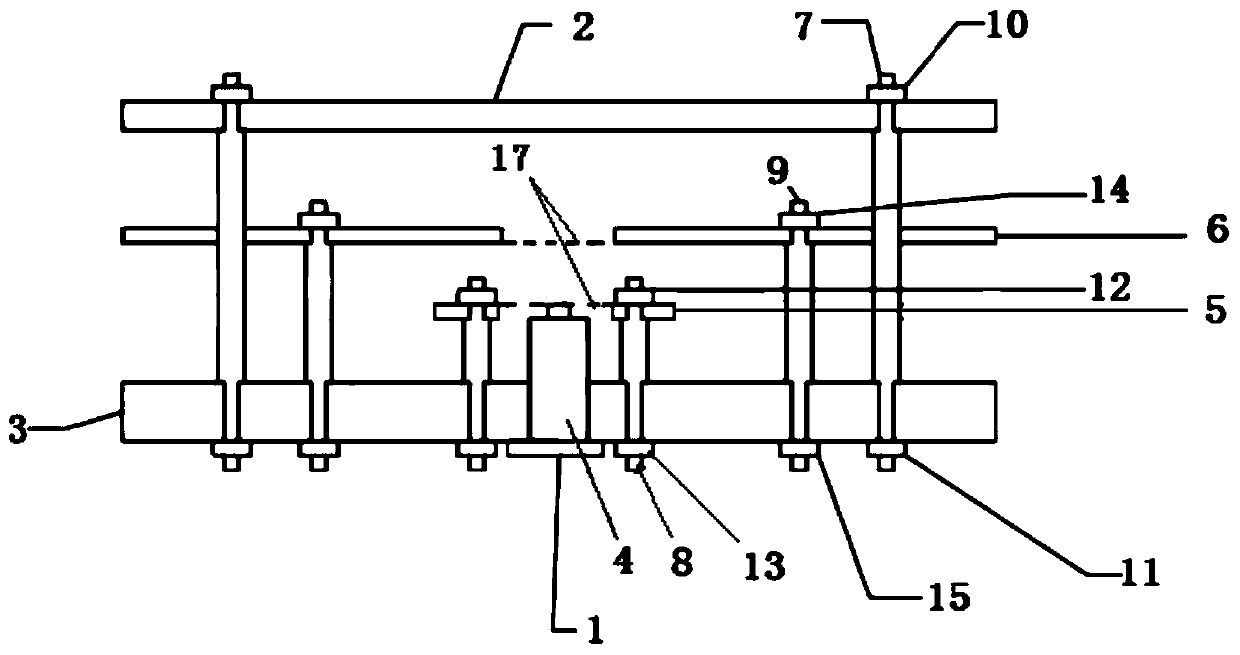

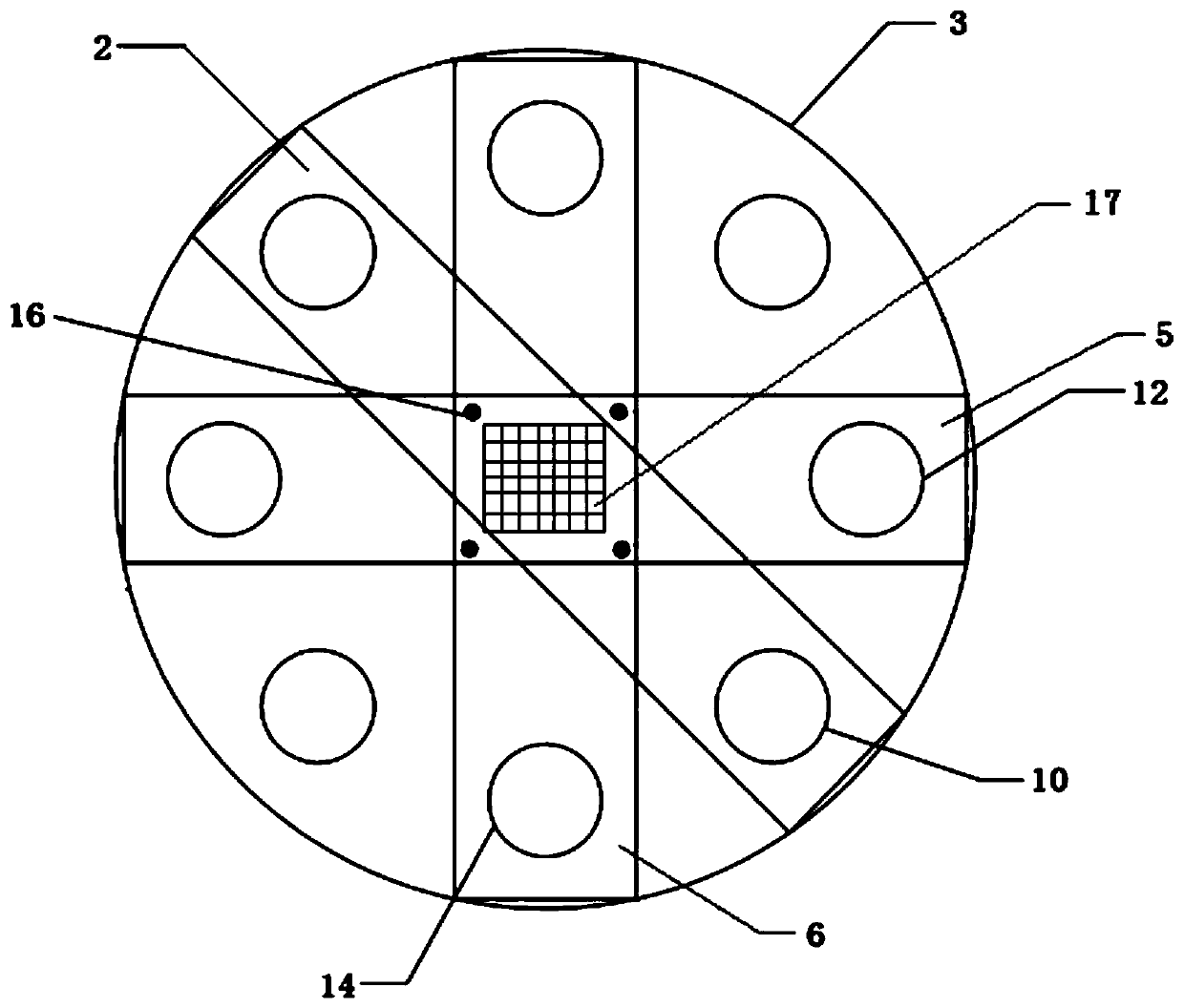

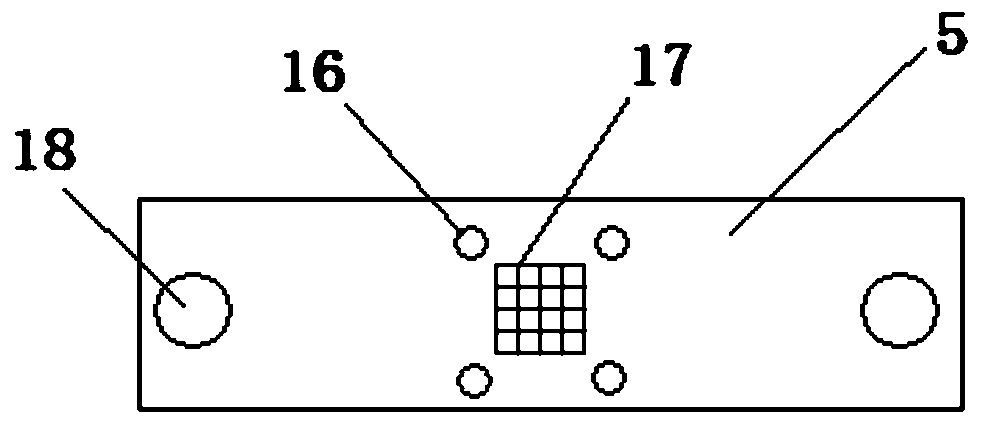

[0024] Such as Figure 1-5 As shown, a field emission high-precision double-grid structure for reducing electron interception, including a cathode substrate 1, a ceramic base plate 3, a cathode 4, a first grid metal sheet 5, a second grid metal sheet 6, and an anode plate 2 , the first ceramic column 7, the second ceramic column 8 and the third ceramic column 9; the anode plate 2 is arranged above the ceramic base plate 3, and the anode plate 2 and the ceramic base plate 3 are connected by two first ceramic columns 7, The second grid metal sheet 6 has the same structure as the first grid metal sheet 5, and the central part is provided with a grid 17, and four of the grid 17 are provided with four mutually symmetrical and identical positioning holes 16; The mesh metal sheet 5 is arranged between the anode plate 2 and the ceramic bottom plate 3, and the first grid metal sheet 5 and the ceramic bottom plate 3 are connected by two second ceramic columns 8; the second grid metal sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com