Electronic louver film based on PDLC liquid crystal light adjusting film, glass and control system

A liquid crystal dimming film and liquid crystal dimming technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of not being able to meet the requirements of transparency or frosting, high working voltage, and low practicability, so as to reduce light pollution and power consumption Low, the effect of shielding infrared rays and ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Fabrication of PDLC liquid crystal dimming electronic louver film and electrode 7 processing

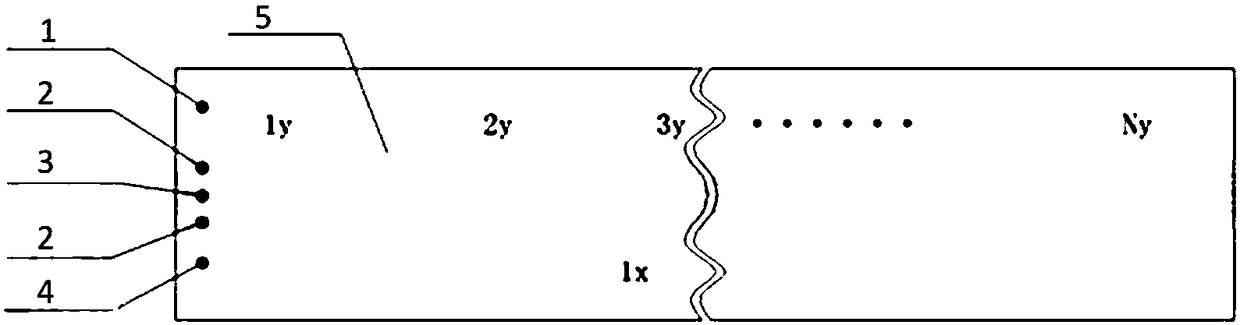

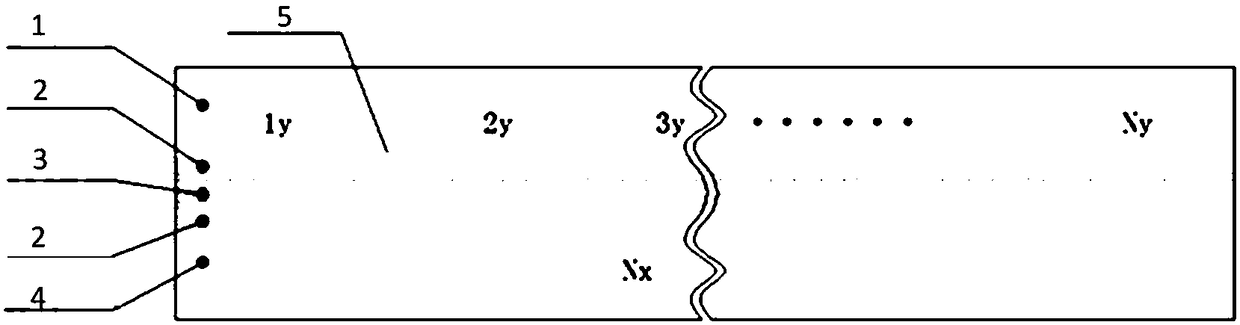

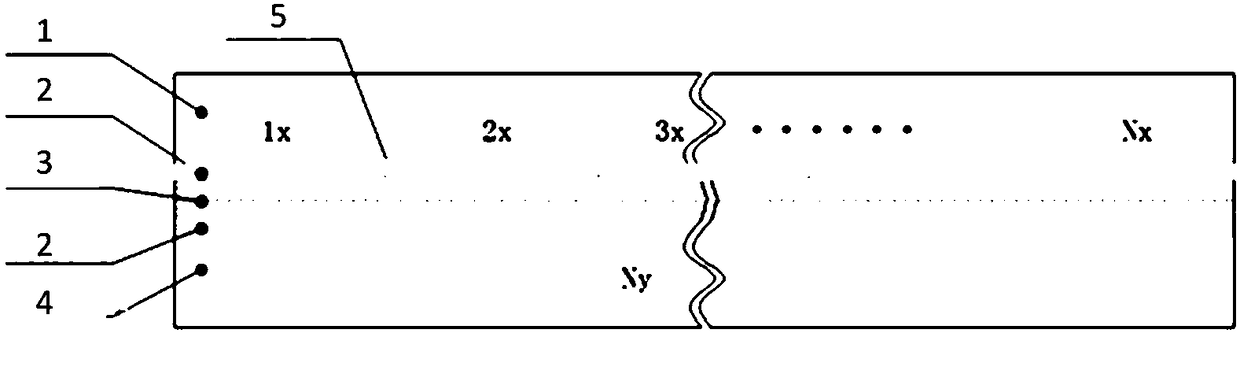

[0050] Such as Figure 1-Figure 6 As shown, 1. First, the ITO target is sputtered onto the PET film by a magnetic sputtering device to produce a PET-ITO conductive film, and then the ITO conductive film on the PET substrate is processed horizontally and vertically by using a laser etching machine. , curves, and patterns are laser etched, and the depth of the etching line 5 is based on cutting off the ITO conductive film. Description: Etching a piece of ITO conductive film can be made into 1 X ×N Y Matrix PET-ITO conductive layer; etching two ITO conductive films can be made into N X ×N Y Matrix PET-ITO conductive layer.

[0051] 2. When preparing the PDLC dimming liquid crystal film, choose a PDLC liquid crystal composition with a wide viewing angle patent No. CN105602578A of Chengzhi Yonghua Company to overcome the low transmittance and narrow viewing angle of...

Embodiment 2

[0056] Example 2: Production of PDLC liquid crystal dimming electronic louver glass

[0057] Such as Figure 7 As shown, PDLC liquid crystal dimming electronic louver glass includes electronic louver components for processed electronic louver glass, two pieces of imported EVA interlayer film, and two pieces of high-quality automotive-grade float glass. On a piece of cleaned high-quality automotive-grade float glass, spread a piece of EVA interlayer film, and then spread the processed liquid crystal film assembly for dimming glass to align with the glass edge or distance from the glass center, and then spread a piece of EVA interlayer film, and finally Lay a piece of cleaned high-quality automotive-grade float glass; remove the excess EVA interlayer on the edge of the glass; put on a vacuum silicone strip to complete the lamination. Vacuum composite molding is completed in five stages: vacuum cold pumping (the vacuum degree is above 700mm / Hg, and the vacuum is guaranteed to be...

Embodiment 3

[0058] Example 3: PDLC liquid crystal dimming electronic shutter film control system

[0059] A PDLC liquid crystal dimming electronic shutter film control system, refer to Figure 8 As shown, the control system is applied to the PDLC liquid crystal dimming electronic shutter film of Embodiment 1 and the PDLC liquid crystal dimming electronic shutter glass of Embodiment 2. The control system includes a power input terminal 12, a wireless receiving module, a WI-FI control module, an MCU and a plurality of electronic control units 13 of the electronic louver matrix. Among them, the wireless receiving module, WI-FI receiving module, MCU and several electronic louver film matrix electronic control units 13 are integrated in the main control box, the power input terminal 12 is provided with a power plug, and an isolated lightning protection Transformer 220V becomes 36V AC to supply power to the electronic louver.

[0060] A remote controller 14 is provided remotely, and a control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com