Drilling in-situ testing device for testing mechanical parameters of engineering rock mass and use method of drilling in-situ testing device

A technology of rock mechanics and in-situ testing, applied in measuring devices, scientific instruments, instruments, etc., can solve the problems of lack of independent intellectual property rights and creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

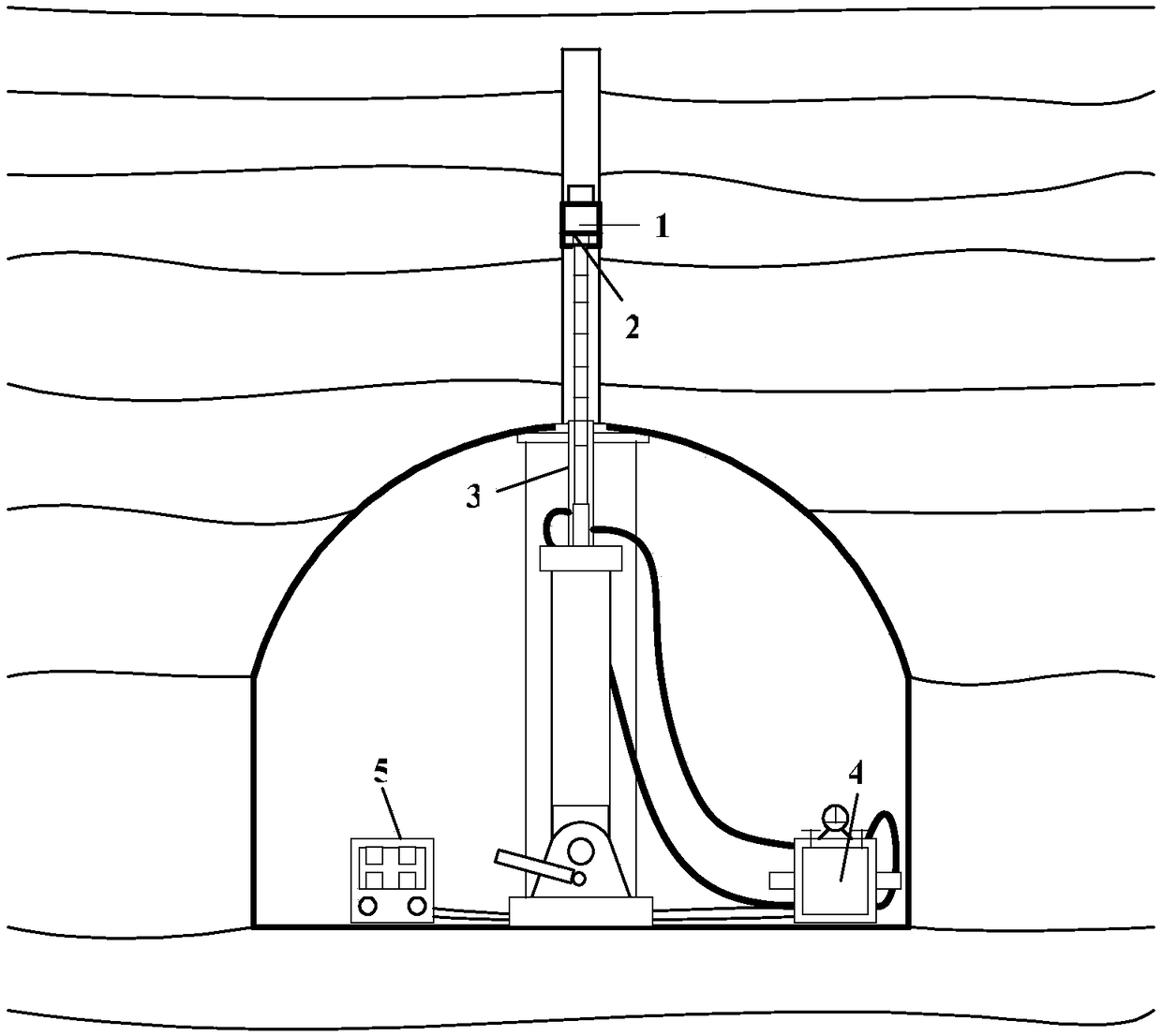

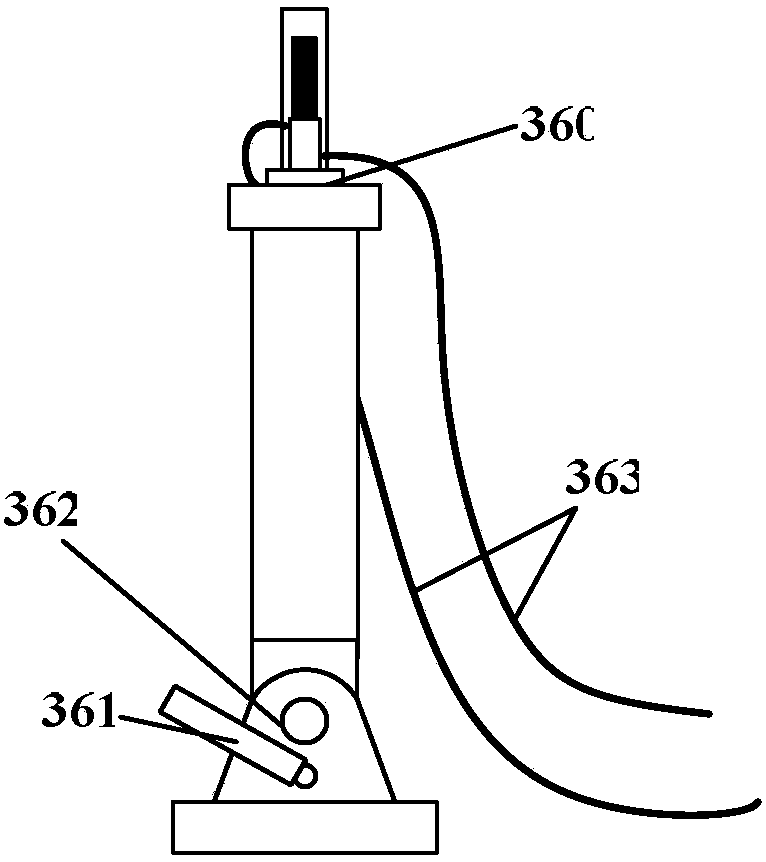

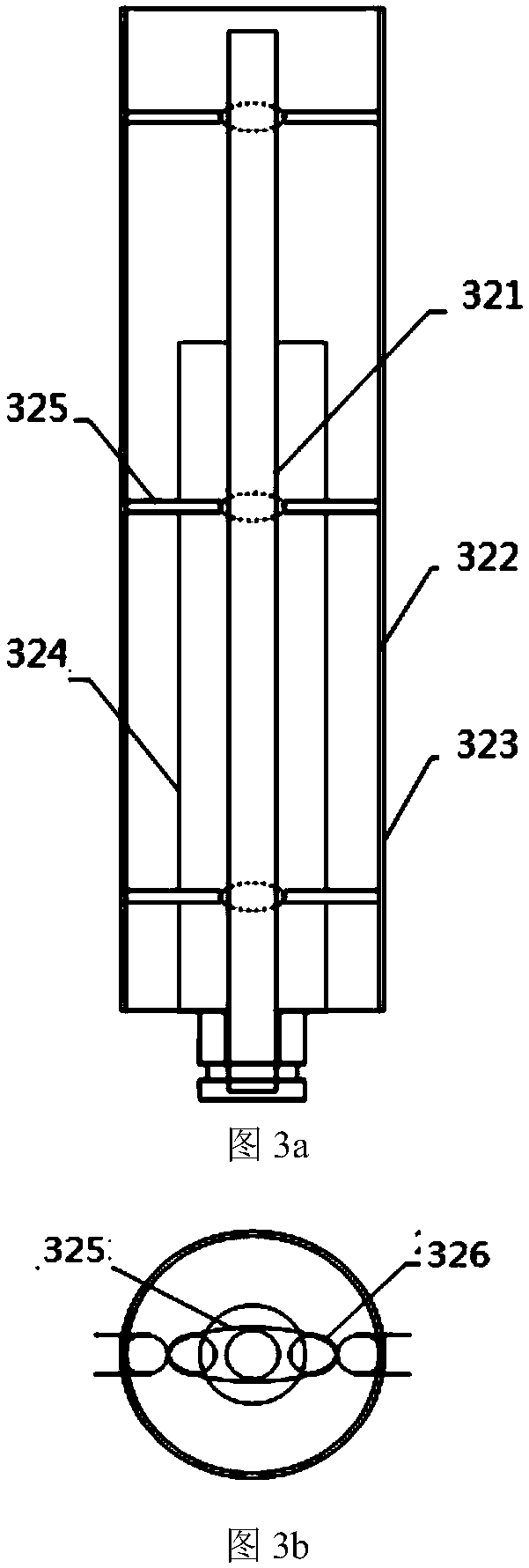

[0074] Such as figure 1 The shown in situ testing device for mechanical parameters of engineering rock mass of the present invention includes penetrating loading system 1, multi-point testing rotary positioning system 2, propulsion support system 3, hydraulic loading system 4 and control system 5 five parts; wherein :

[0075] (1) The structure of the penetrating loading system 1 is as follows: Figure 9-10 As shown, the whole includes a single-point loading instrument 11, a video acquisition unit 14, a displacement measurement unit 15, a penetrating cone head 120, and a pressure-bearing base 119;

[0076] As can be seen from the figure, the single-point loading instrument 11 is provided with a cavity 12 at the top and a pressure chamber 117 at the bottom, and the penetration cone 120, that is, the bottom of the piston head, passes through the cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com