A multi-bolt loosening test machine under combined loading of flanges under tension, bending and torsion

A composite loading and testing machine technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

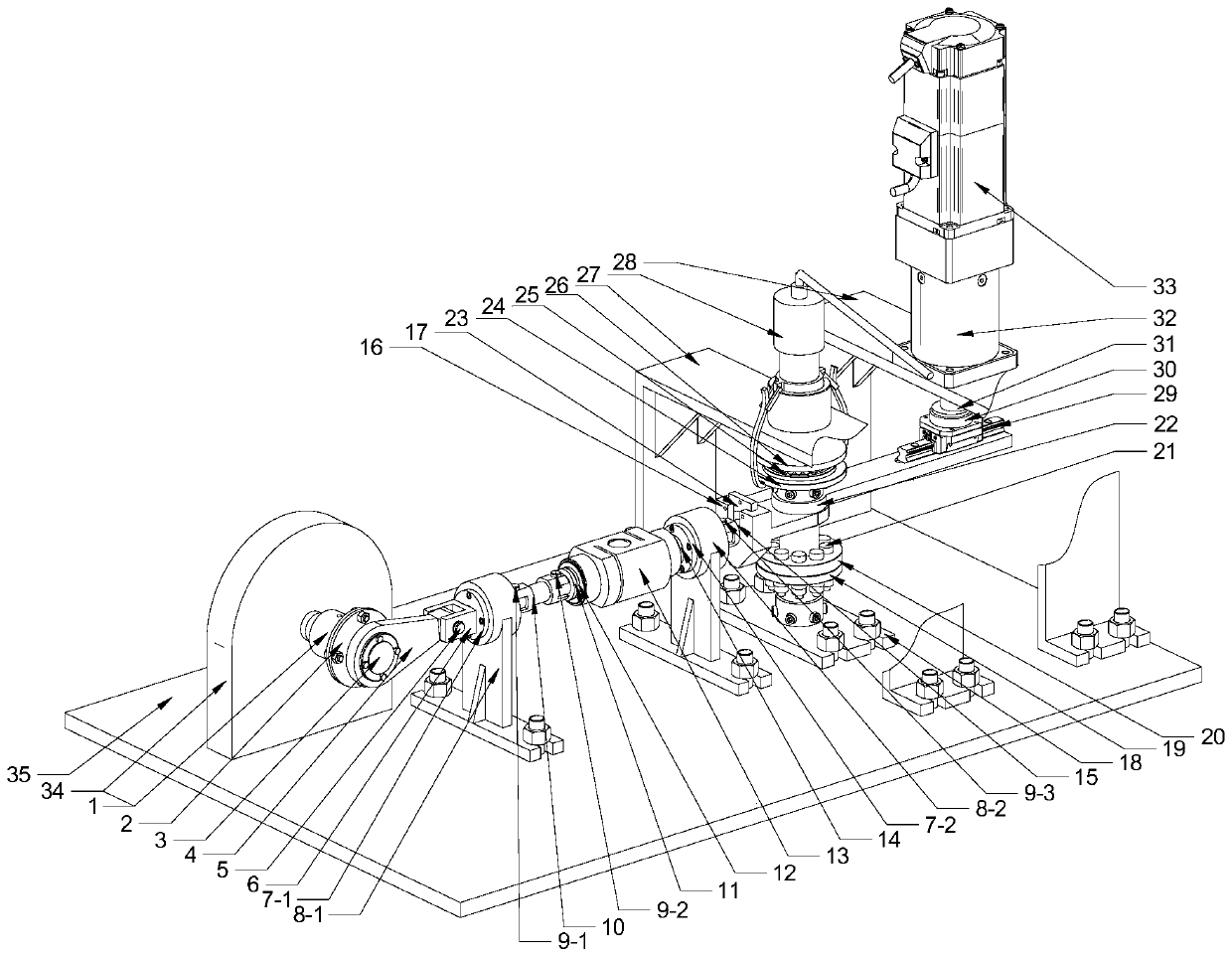

[0020] Such as figure 1 Shown:

[0021] A multi-bolt loosening testing machine for flanges under combined tension-bending-torsion loading is composed of three parts, namely an axial load transmission part, a lateral load transmission part and a torque load transmission part;

[0022] The axial load transfer part includes a lower clamping plate 18, a thin test piece 19, a thick test piece 20, a test piece bolt 21, a bearing cap 23, a thrust ball bearing 24, an upper clamping plate 25, and an axial load support 26 and hydraulic puller 27; the lower clamping plate 18 and the axial loading support 26 are all fixed on the abutment 35; the thin test piece 19 and the thick test piece 20 are assembled together correspondingly, and the The bolts 21 are fixed in the corresponding bolt holes; the thin test piece 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com