Cement standard denseness water consumption metering device and method

A standard consistency and measuring device technology, applied in measuring devices, weighing, instruments, etc., can solve the problems of data unit inconsistency, error, water density and temperature influence, etc., to achieve accurate mass measurement, high precision, and avoid reading effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

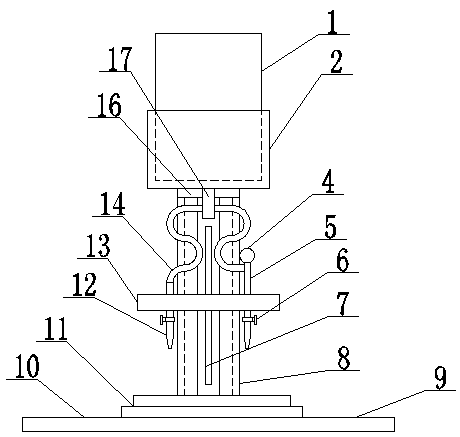

[0030] A cement standard consistency water consumption metering device, which consists of: a bracket 9, the upper part of the bracket is fixedly connected with the ring seat 2 through a support plate 15, a water tank 1 is placed in the ring plate, and the water tank The lower main water pipe 17 is fixedly connected with the water distributor 5, and the water distributor includes the main water outlet pipe 12 and the glue head dropper 4, and the lower part of the main water outlet pipe and the glue head dropper are fixed on the fixed plate In the round hole 20 of 13, the main water outlet pipe and the upper part of the glue head dropper are fixedly connected to the main water pipe through the hose 14 respectively, and the main water outlet pipe and the glue head dropper Ball valves 6 are respectively installed in the lower part.

Embodiment 2

[0032] According to the cement standard consistency water metering device described in Example 1, the support includes a base 10, the upper part of the base is fixedly connected with the vertically arranged channel steel 8, and the upper part of the channel steel is fixed with the connecting plate 16 connected, an electronic balance 11 is fixed on the base.

Embodiment 3

[0034] According to the cement standard consistency water metering device described in embodiment 1 or 2, the fixed plate is fixedly connected to the right end of the cross plate 19, the left side of the cross plate is located in the channel steel, and the The left end of the cross plate passes through the strip hole 7 on the channel steel and is connected with the channel steel by a nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com