Ultra-large-scale real-time distributed strain measurement system

A distributed strain and measurement system technology, applied in the field of ultra-large-scale real-time distributed strain measurement system, can solve the problems of high test cost, long time-consuming, difficult to guarantee test accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

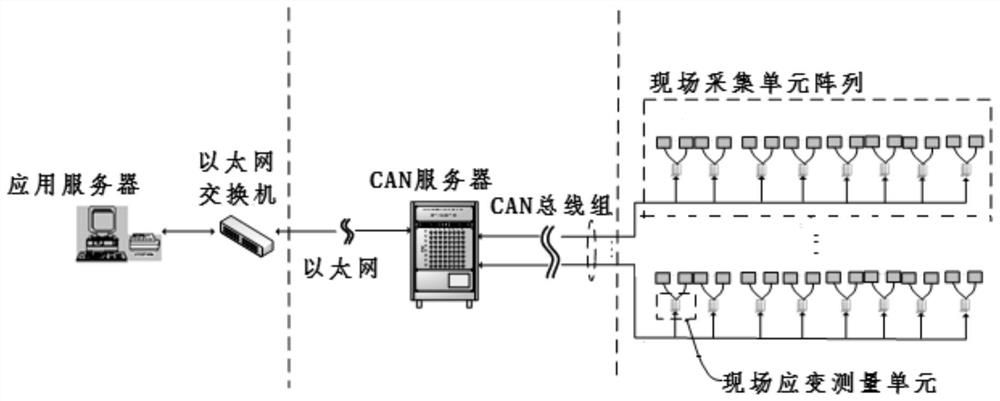

[0026] The present invention provides a super-large-scale real-time distributed strain measurement system, see figure 1 , including an application server and at least one CAN server connected to the application server, each CAN server is connected to multiple field acquisition unit arrays through a multi-channel CAN bus; the CAN server can control multiple The on-site acquisition unit array synchronously collects strain information, and the on-site acquisition unit array transmits the collected strain information to the CAN server through the CAN bus, and the CAN server transmits the strain information to the application server through the Ethernet. Through the above-mentioned technical solution, a three-layer architecture is adopted, including on-site acquisition unit array, CAN server and application server, to realize synchronous acquisition of strain signals by multiple on-site acquisition unit arrays, and to solve the front-end acquisition, communication and synchronizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com