Device for detecting sizes of displacement type segmented round steel and ribbed steel bar

A ribbed steel bar, dimension detection technology, applied in the direction of measuring device, optical device, mechanical gap measurement, etc., can solve the problems of inconvenience, use limitation, lack of online adjustment function of center measurement, etc., to achieve simple and convenient combination and easy work. free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

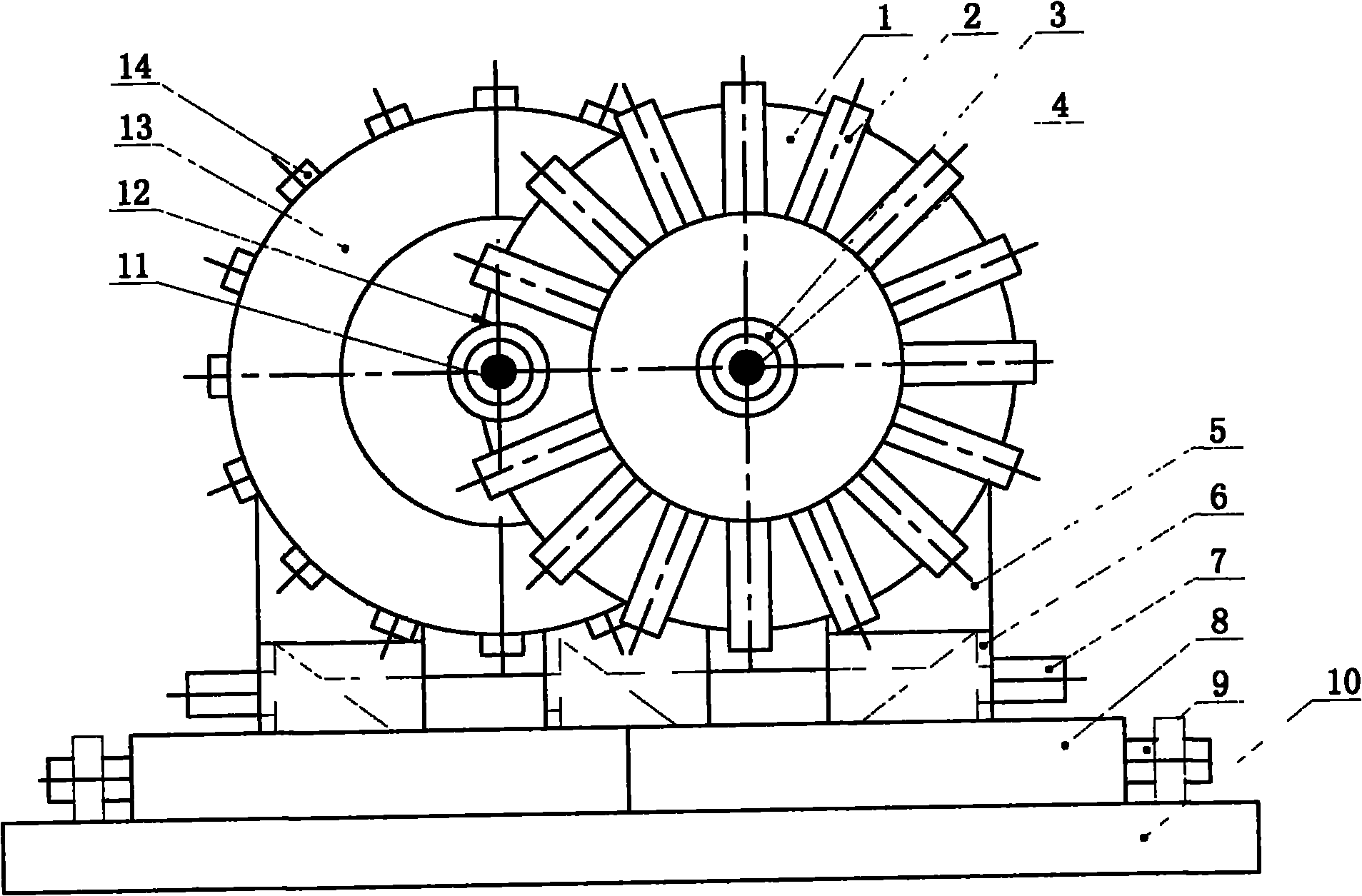

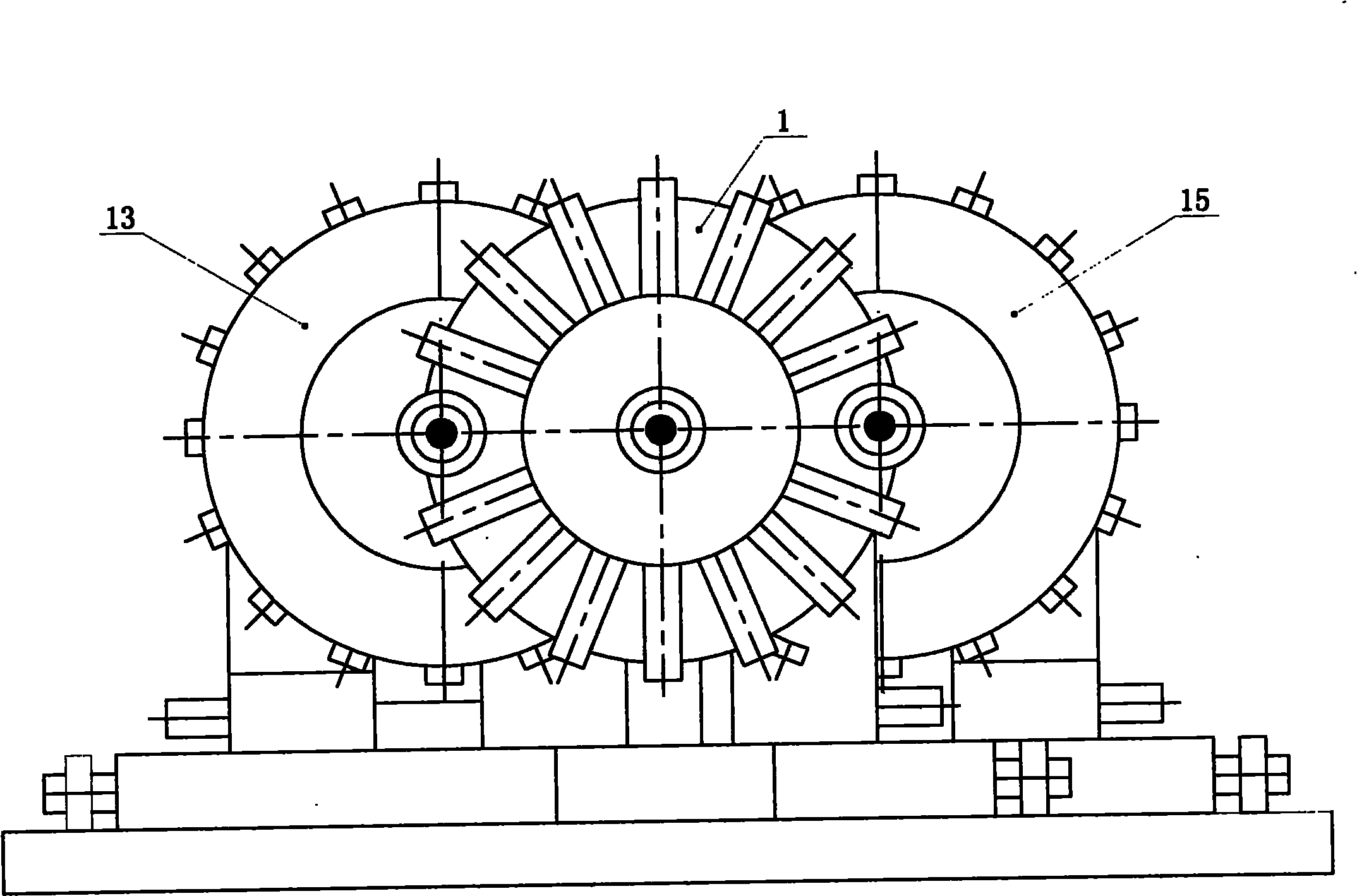

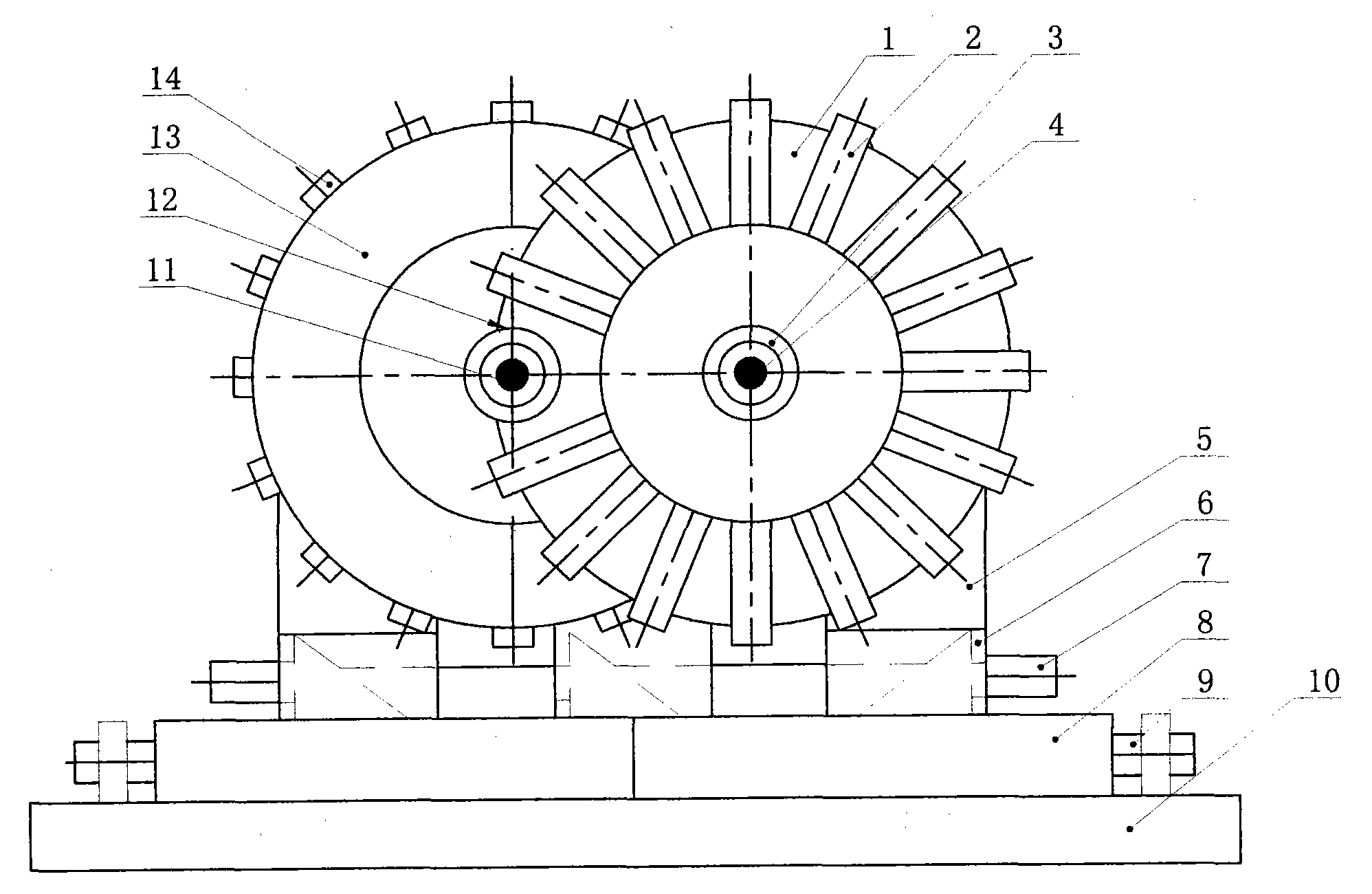

[0019] A displacement-type segmented round steel and ribbed steel bar size detection device includes a main detection unit composed of a detection main plate 1, a measuring head 2, a vertical adjustment seat 6 and a horizontal adjustment seat 8. The center of the detection main disk is formed with an over-rigid channel 4 for the rolled material to pass through. On one side of the detection main disk, measuring heads are equidistributed and uniformly distributed. The measuring heads include symmetrically arranged transmitting and receiving measuring heads. A vertical adjustment seat is installed on the lower part of the detection main disk, and the lower part of the vertical adjustment seat is installed on a horizontal adjustment seat, and the horizontal adjustment seat is installed on a base 10 .

[0020] The innovation of this de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com