Method and device for controlling opening degree of external bed ash control valve

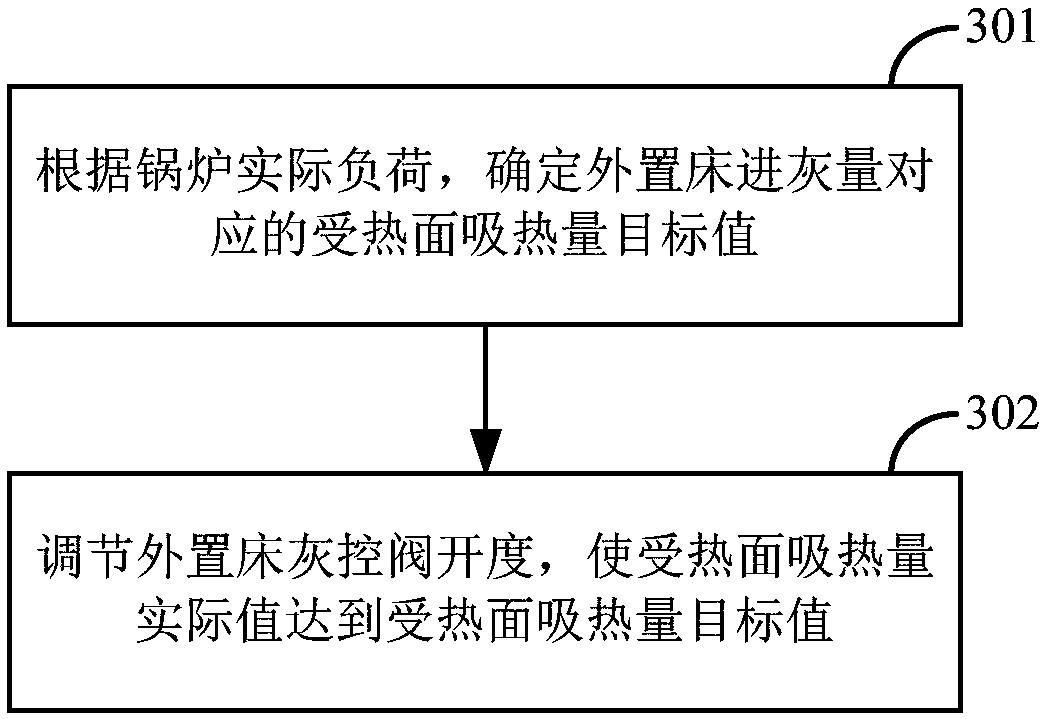

A control method and an external bed technology, applied in the field of boiler control, can solve the problems of reduced combustion efficiency, coordinated supply, unfavorable fuel volume and air volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0026] The technical terms involved in the embodiments of the present invention are briefly described below:

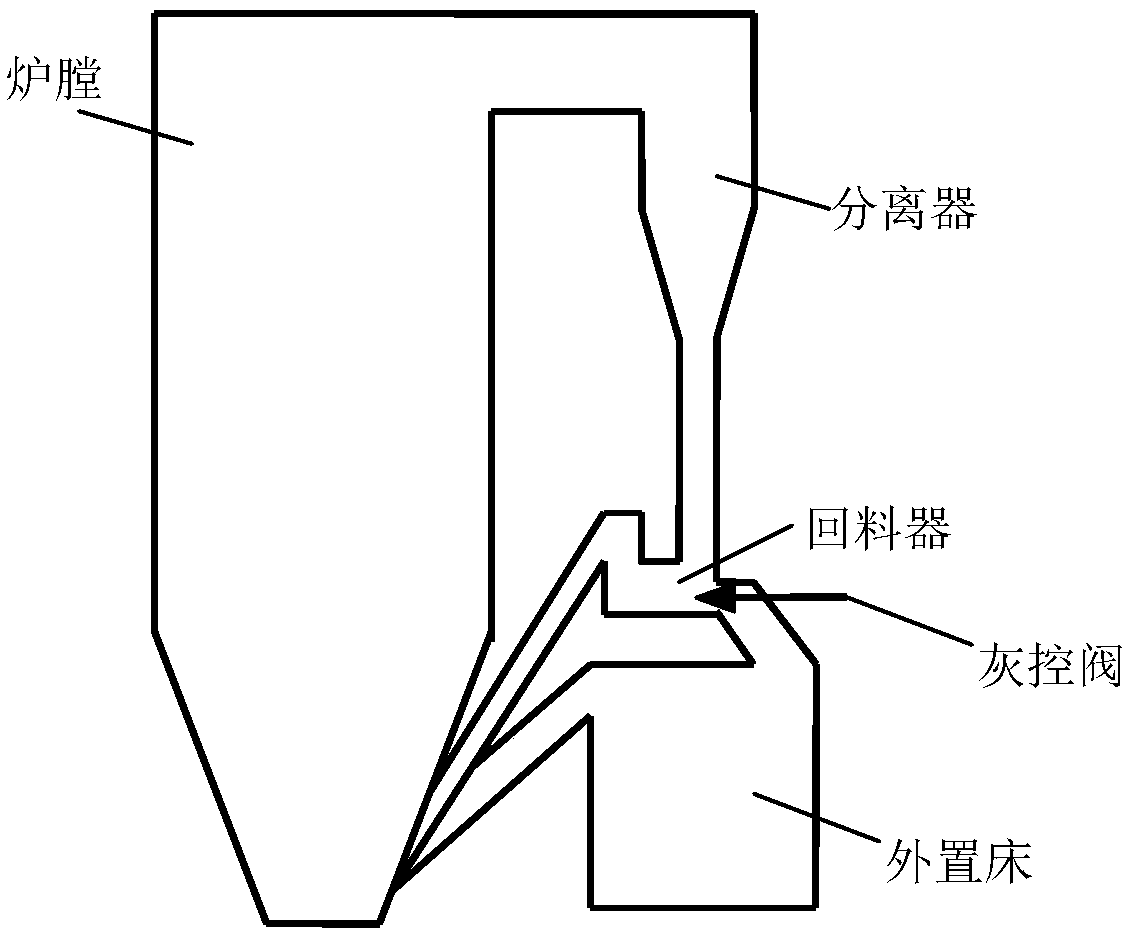

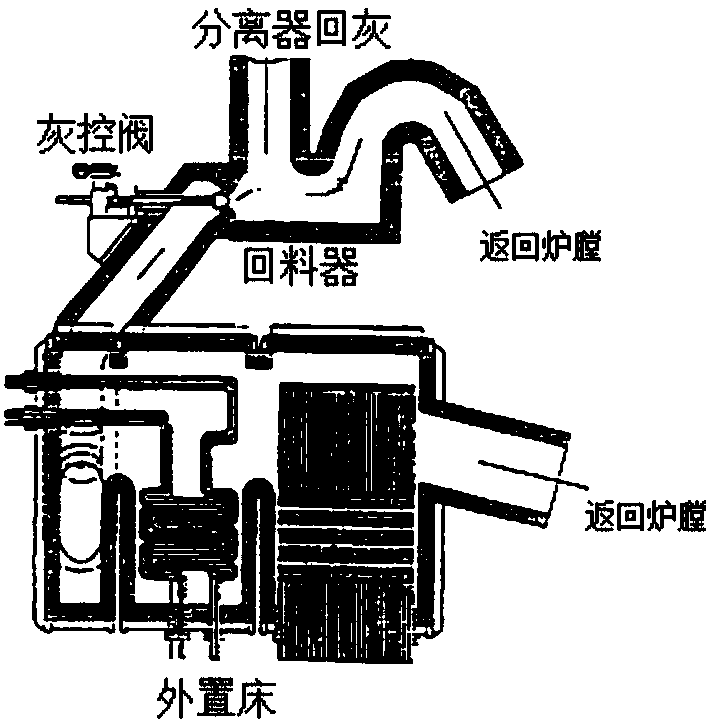

[0027] Circulating fluidized bed boiler: a boiler that uses the principle of circulating fluidized bed reactor to burn coal and other low-quality fuels. It is mainly composed of furnace, cyclone separator, return valve and tail flue. It is widely used in industrial steam supply and In the field of thermal power generation, it has outstanding advantages in environmental protection and comprehensive treatment of pollutants. figure 1 It is an example diagram of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap