A kind of preparation method of low surface energy foamed polyester fabric

A low surface energy material, polyester fabric technology, applied in physical treatment, textiles and papermaking, liquid repellent fibers, etc., can solve the problems of complex production process, environmental pollution, a large amount of industrial waste water, etc., to achieve convenient operation, process Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

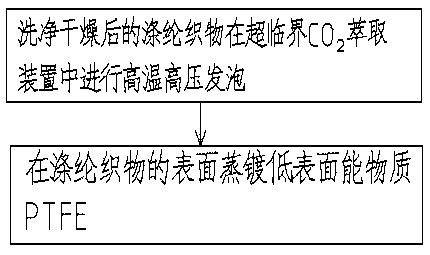

[0029] Such as figure 1 Shown, the present invention provides a kind of preparation method of low surface energy foaming polyester fabric, comprises the steps: Step 1: the polyester fabric after cleaning and drying is in supercritical CO 2 Foaming is carried out in the extraction device; step 2: evaporating low surface energy material PTFE on the surface of the foamed polyester fabric.

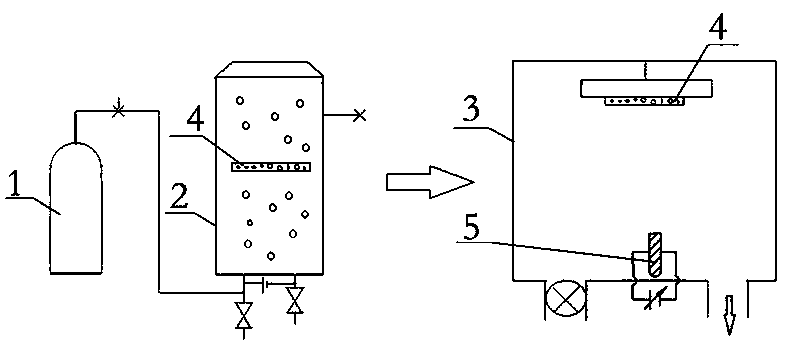

[0030] The above-mentioned preparation method adopts such as figure 2 The preparation setup shown includes CO 2 Gas storage tank 1, foaming kettle 2 and low surface energy material PTFE evaporation chamber 3, said foaming kettle 2 is supercritical CO 2 extraction unit, the CO 2 The gas outlet of the gas storage tank 1 is connected to the air inlet at the bottom of the foaming kettle 2 through a pipeline. When foaming, the polyester fabric is placed in the inner middle of the foaming kettle 2, and the foaming kettle 2 is filled with supercritical CO2 from bottom to top. 2 gas. During eva...

Embodiment 1

[0038] A method for preparing a low surface energy foamed polyester fabric, the specific steps are: cutting the polyester white gray cloth into 40cm×15cm, soaking the polyester white gray cloth in hot soapy water at 60°C for 15 minutes; rinsing the excess foam with clean water after washing foam, then placed in an ultrasonic cleaning machine filled with absolute ethanol for 15 minutes of ultrasonic cleaning; after ultrasonic washing, rinse excess ethanol with water, and finally rinse with deionized water, and dry in an oven at 80°C. Put the dried polyester white gray cloth into supercritical CO 2 In the extraction device, the temperature is set to 150°C, the pressure in the foaming tank rises to 10MPa, and the pressure is maintained for 10h, and the supercritical CO 2 It can be fully dissolved in the polyester fabric, and the pressure can be released quickly to make a porous foamed polyester fabric.

[0039] In the low surface energy material PTFE evaporation chamber, fix the...

Embodiment 2

[0041] A method for preparing porous polyester fabric with low surface energy, the specific steps are: cutting the polyester white gray cloth into 40cm×15cm, soaking the polyester white gray cloth in hot soapy water at 60°C for 15 minutes; rinsing the excess foam with clean water after washing , and then placed in an ultrasonic cleaning machine filled with absolute ethanol for ultrasonic cleaning for 15 minutes; after ultrasonic cleaning, rinse the excess ethanol with water, and finally rinse it with deionized water, and dry it in an oven at 80°C. Put the dried polyester white gray cloth into supercritical CO 2 In the extraction device, the temperature is set to 180°C, the pressure in the foaming tank rises to 20MPa, and the pressure is maintained for 24h, and the supercritical CO 2 It can be fully dissolved in the polyester fabric, and the pressure can be released quickly to make a porous foamed polyester fabric.

[0042] In the low surface energy material PTFE evaporation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com