Spinning dust collection device

A technology of dust collection and weaving, which is applied in the direction of weaving, combined devices, textiles and papermaking, etc. It can solve the problems of dust collection and poor cleaning effect, and achieve the effects of avoiding secondary dust, good dust removal effect and good working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

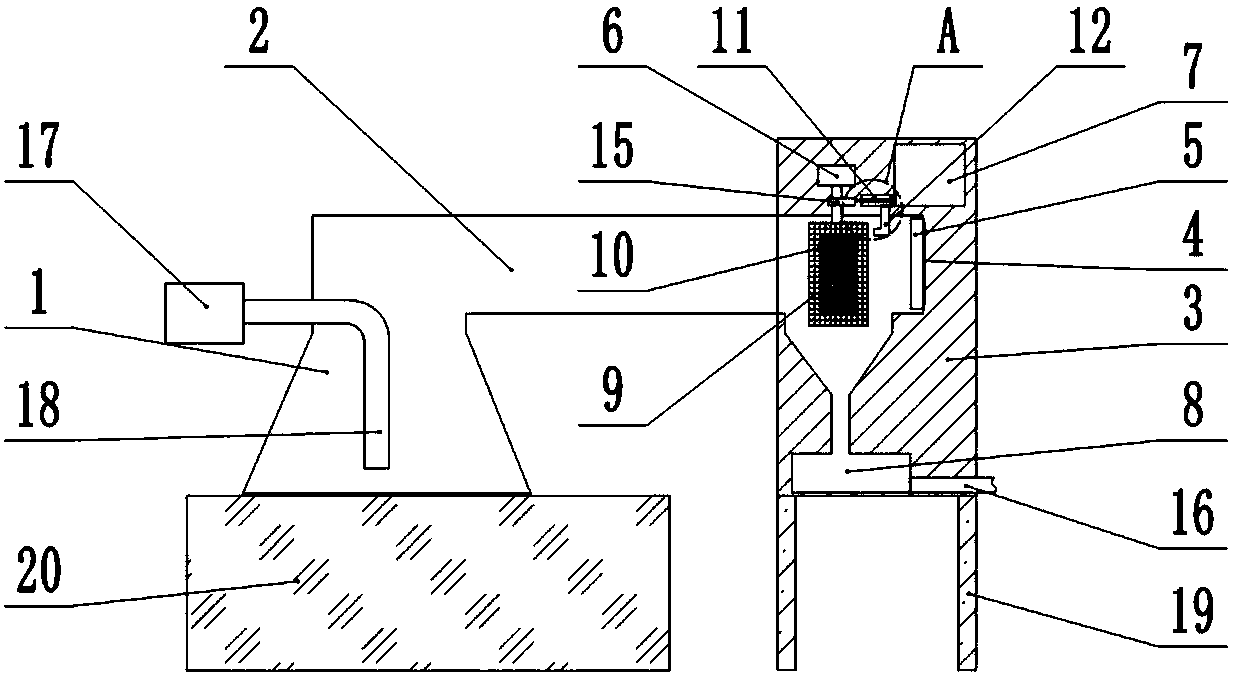

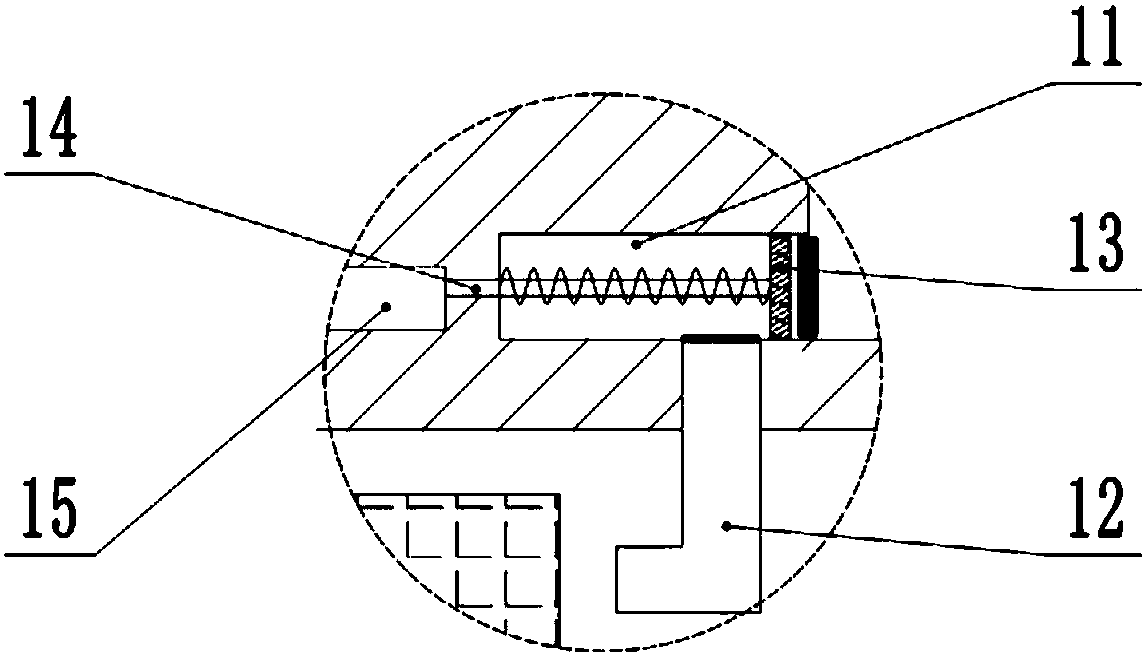

[0025] basically as figure 1 Shown: a textile dust collection device, including a first dust suction pipe 1, a second dust suction pipe 2 and a dust collection box 3, the first dust suction pipe 1 and the second dust suction pipe 2 are perpendicular to each other and connected, the first The opening of the dust suction pipe 1 is downward and the opening of the first dust suction pipe 1 is a wide mouth, the dust collection box 3 is located at the right end of the second dust suction pipe 2 and the end of the second dust suction pipe 2 extends into the dust collection box 3 Inside. The side wall of the second suction pipe 2 right-hand side is provided with an exhaust port 4, and the exhaust port 4 is provided with a screen, and the left side of the exhaust port 4 is provided with a first negative pressure fan 5.

[0026] A motor 6, a water tank 7 and a waste water pool 8 are fixed in the dust collection box 3, the motor 6 and the water tank 7 are positioned above the second suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com