A low dielectric constant temperature stable microwave medium and its preparation method

A temperature-stable, low-dielectric-constant technology, applied in the field of low-dielectric constant, microwave dielectric ceramics with near-zero frequency temperature coefficient and its preparation, low-dielectric constant temperature-stable microwave media and its preparation, can solve the problem of resonance Negative frequency temperature coefficient cannot meet application requirements, change dielectric constant, affect practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

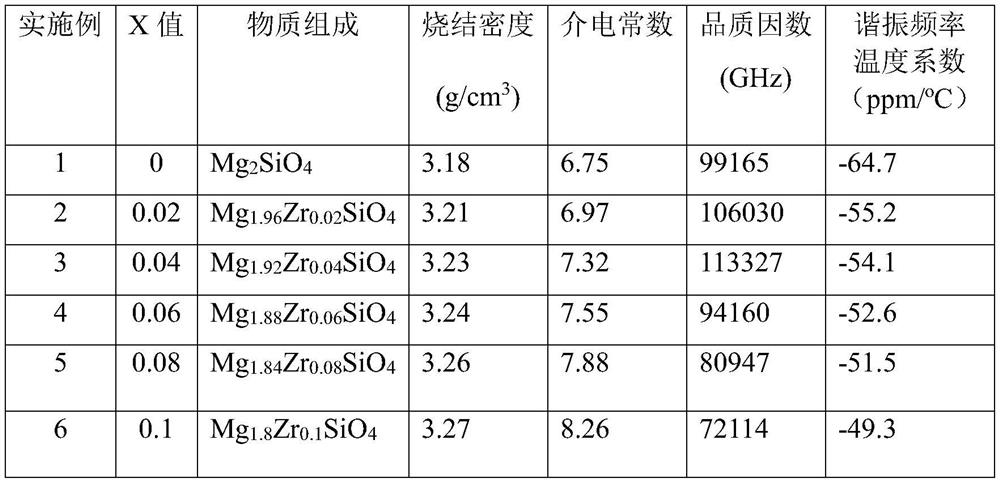

[0030] The raw material MgO and SiO with a purity of 99.9% 2 And ZrO 2 According to the molar ratio of Mg:Si:Zr as 2:1:0 ingredients, where x=0; after mixing, it is fully ball milled at 200r / min for 4h, dried at 120°C, passed through a 60-mesh sieve, and placed in a corundum crucible. Then keep it at 1050℃ for 4h to get Mg 2 SiO 4 , Its performance test is shown in Table 1.

Embodiment 2

[0032] The raw material MgO and SiO with a purity of 99.9% 2 And ZrO 2 According to the molar ratio of Mg:Si:Zr as 1.96:1:0.02 ingredients, where x=0.02; after mixing, it is fully ball milled at 200r / min for 4h. After ball milling, it is dried at 120°C, passed through a 60-mesh sieve, and placed in a corundum crucible. Then keep it at 1050℃ for 4h to get Mg 1.96 Zr 0.02 SiO 4 , Its performance test is shown in Table 1.

Embodiment 3

[0034] The raw material MgO and SiO with a purity of 99.9% 2 And ZrO 2 According to the molar ratio of Mg:Si:Zr is 1.92:1:0.04, x=0.04; after mixing, it is fully ball milled at 200r / min for 4h, dried at 120°C, passed through a 60 mesh sieve, and placed in a corundum crucible. Then keep it at 1050℃ for 4h to get Mg 1.92 Zr 0.04 SiO 4 , Its performance test is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com