Purifying device and manufacturing process of low energy consumption lithium battery graphite negative electrode material

A technology of graphite anode and lithium battery, applied in battery electrodes, sustainable manufacturing/processing, circuits, etc., can solve the problems of limited cooling method, low quality of recarburizer, uneven degree of graphitization, etc., achieving remarkable environmental protection and energy saving, High degree of graphitization and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

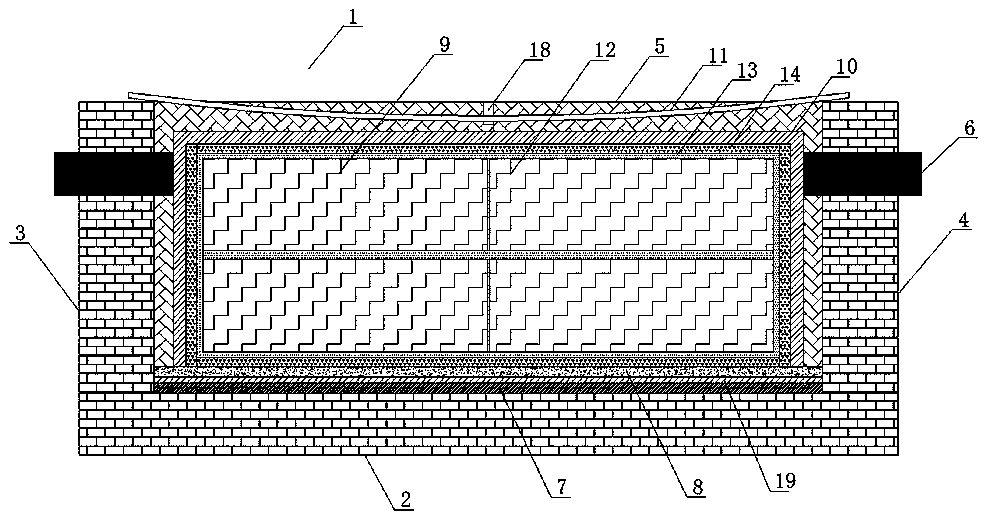

[0028] Embodiment 1: A manufacturing process of a low-energy lithium battery graphite negative electrode material purification device, comprising the following specific steps:

[0029] Step 1: Laying quartz sand and coke powder on the furnace base 2 in sequence, and compacting them;

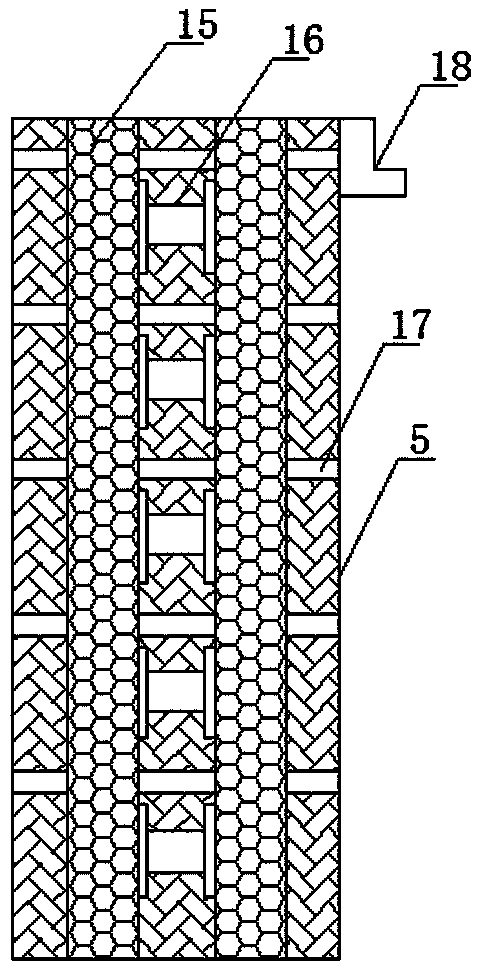

[0030] Step 2: Then hoist and fix the furnace wall panel 5, and seal the side of the Acheson furnace main body 1;

[0031] Step 3: Hoist the forming board 10 and the steel plate in turn on the inner side of the furnace wall board 5, and reserve a space between the furnace wall board 5 and the forming board 10 filled with thermal insulation materials, and reserve a space filled with petroleum coke between the forming board 10 and the steel plate spacing, and then respectively fix the forming plate 10 and the steel plate;

[0032]Step 4: Then lay petroleum coke on the upper part of the coke powder and tamp it, then lay calcined coke on the upper part of the petroleum coke and tamp it;

[0033] St...

Embodiment 2

[0037] Embodiment 2: a kind of energization heating curve, comprises the following stages:

[0038] The first stage: the transmission power is 100~150KW, and the time is 8~20 hours;

[0039] The second stage: maintain the temperature at the end of the first stage for 10-12 hours, and keep the power transmission at 100-150KW;

[0040] The third stage: the transmission power is 180 ~ 450KW, and it is maintained for 8 hours;

[0041] The fourth stage: According to the rated power and rated voltage of the transformer, the power of the power transmission is increased freely. After the temperature is measured by the infrared thermometer, when the temperature reaches above 3000 degrees, keep it for 10 hours, downshift and cut off the power, and the power transmission ends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com